An Australian company is commercializing an unusual 3D metal printing process.

Titomic, based in Melbourne, uses an unusual 3D printing process originally developed by CSIRO, the Australian research agency.

Their process employs kinetic fusion, the mechanical bonding of like particles when sufficient impact is employed. Their 3D printer essentially sprays “cold” metal particles at a target where they naturally fuse together without the need for heating, lasers or other high temperature mechanisms.

By moving the spray application they can gradually build up 3D objects. However, there’s another twist here: their process is to spray metal particles onto an existing scaffold. By gradually adding layers of material to the scaffold they can produce a far stronger object made from metal. However, the scaffold will be embedded within after 3D printing completes.

The process allows them to build parts on a flat base, too, which matches the capabilities of other 3D metal printing processes. But they can, for example, 3D print a bicycle frame in metal by coating a frame with titanium. It’s not clear what the scaffold is made from, but it should be a hard material that would not be affected by high-impact metal particles.

This process is quite interesting, and from the company’s videos it seems they can apply it in different ways: a stationary spray applicator blasts a 3D moving scaffold; a moving spray applicator deposits material in layers.

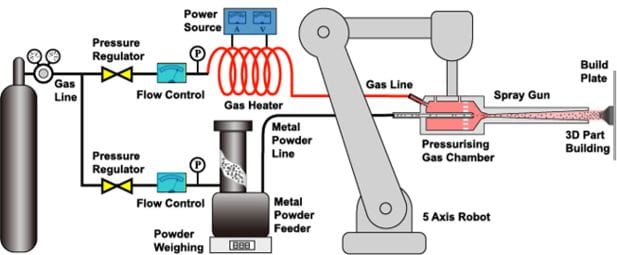

The process requires input high pressure gas, which is split into two flows. One flow drives the metal particles, and the other is heated. The heat is not sufficient to melt the particles, but rather is present to ensure proper particle flow.

One important advantage to this approach is that the operator could theoretically mix different metal powders in the input hopper to dynamically create different alloys when 3D printing.

The resulting deposition is quite coarse, and thus this process cannot be used to 3D print smaller detailed objects. However, it is quite fast and should be very applicable for the production of larger metal objects.

The coarseness, however, may demand some post processing to smooth the surfaces in some cases.

This is an interesting process, and is one of many more inexpensive processes that are attacking the traditional 3D metal printing approaches. For now, however, I suspect the traditional producers will focus on the pricey certified markets such as automotive, aerospace and medical, while the lower priced technologies such as those from Titomic will likely find success on markets that haven’t been able to afford traditional 3D metal printing options.

Via Titomic