nScrypt, a manufacturer of industrial 3D printers and bioprinting tools, has announced the ability to 3D print medical implants with embedded circuits and sensors.

The goal of the technology is to be able to monitor the health of both the device and the patient.

Florida-based nScrypt is a unique company, in that it has developed a range of industrial 3D printing and bioprinting technology capable of fabricating parts with very specific applications. For instance, the firm has developed tools such as a microdispensing SmartPump, as well as a high precision pick-and-place system with ≤2 micron repeatability. nScrypt’s 3Dn Bio Assembly Tools will even be used in 2019 on the International Space Station, where they will be used to print beating heart patches.

For this latest achievement, nScrypt has relied on a polyamide polyolefin and cellulose (PAPC) compound, developed by FibreTuff Medical Biopolymers, that uses FDA-compliant ingredients. The material is meant to be a cost-effective alternative to polyether ether ketone, an industrial plastic known for its many useful physical properties, including strength, heat resistance and biocompatibility.

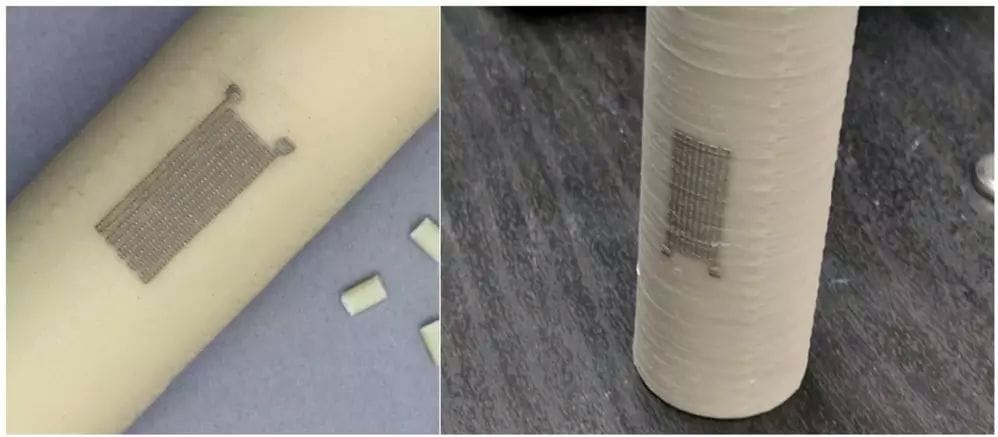

FibreTuff’s PAPC materials provide part strength, layer adhesion and the ability to adhere to specialized coatings. This last feature makes it possible for circuits to be placed on or embedded within PAPC parts, so that sensors can be attached to monitor the health of the part or its surrounding environment. As a result, this process is ideal for 3D printing medical devices or implants so that the embedded sensor can track the health of the part or patient.

Read more at ENGINEERING.com