In a surprise announcement, Stratasys unveiled an apparently new 3D printing technology, “STEP”, and a company to run with it, Evolve Additive Solutions.

“STEP” refers to “Selective Thermoplastic Electrophotographic Process”, and is able to 3D print objects in plastics. Apparently it is a kind of combination of 2D deposition and 3D printing technologies.

They haven’t yet revealed many details about the nature of the STEP technology, focusing mostly on its benefits. But those benefits seem like a fantasy wish list for those close to 3D printing:

- “50x faster” than current 3D printing processes

- Isotropic parts in all dimensions

- Part strength “on par with” or “exceeds the capabilities of” injection molding and CNC milling

- Scalable to large production volumes

- Reliability and yields “comparable to traditional manufacturing”

- Full color capable

- Multimaterial capable – on the same print layer

- Reusable, hands-free support removal (less than 12 hours)

- High resolution, with 0.05mm feature size

- Integration with standard factory software and hardware systems

And finally:

- “Lowest AM cost per part available” and “Cost competitive with injection molding”

Wow! If this is all true, this could be an incredible breakthrough for the industry. It could mean that real, scalable production 3D printing could appear.

But how does STEP actually work? While Stratasys and Evolve Additive Solutions don’t really say, we can make some guesses by watching their video, which, by the way, appears to include a prehistoric image of Stratasys founder Scott Crump with his original kitchen machine in 1988, something I’ve never seen before:

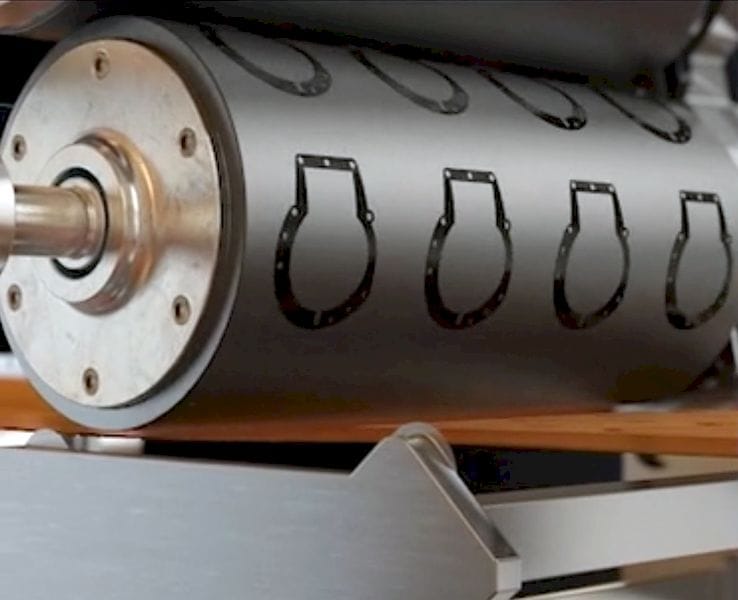

What appears to be happening is something akin to a drum-style photocopier, with material deposited on a precision cylinder that is then rolled to press against the paper, erm, I mean the object.

The system also appears to utilize a conveyor belt approach to production, which matches the roller concept. It is clear how this could be scaled up: the roller repeatedly deposits material on a segment of the conveyor belt, which slides out of the machine when completed. A new belt segment slides in and the process repeats.

2D paper printing technology is quite advanced and can be extremely rapid. While most people are familiar with the relatively slow desktop 2D printers, industrial 2D printers can blast out printed sheets (rolls, actually) at unbelievable speeds. I suspect this is where the speed of the STEP system originates.

For Stratasys, I think this is a blockbuster move. Facing increasing competition from countless lower-priced copycats on their traditional product lines, and from HP at the high end, the STEP technology could open up another avenue for revenue. And it’s a big one.

There are a lot more companies that could buy this technology than traditional 3D printers as we’ve come to know them. Anywhere there is production injection molding equipment, you may, in theory, find a potential customer for STEP equipment.

But there is one catch: none of this is actually available today, it appears. EAS and Stratasys have not announced any specific machine models, pricing or availability dates. In fact, the machine shown seems to be only a rendering, and not an actual machine.

This tells us that they’re still in progress. I have no doubts that Stratasys and team can pull this off, but we just don’t know the details yet. Stratasys says this project has been in incubation for “10 years”, so there’s clearly a lot to this.

I’m sure we’ll be hearing a lot more in coming months.

Via Stratasys