One of the trickier aspects of operating 3D printers for hire is that of pricing prints.

I found this out when first setting up a pricing system for our workshop’s equipment, and it was surprisingly more complex than I had ever imagined.

You’d think it would be straightforward: just figure out the cost of materials for the job in question, and mark it up a percentage. But no, there’s far more than that to consider.

The obvious missing elements in my primitive pricing structure are the cost of labor to operate the device, and the cost of the equipment itself, which must be defrayed over all the jobs that take place on them over their expected lifetimes.

But then it gets more complex, as machine time is incredibly valuable. Thus a job that uses lesser amounts of material in a sparse design takes up considerably more machine time than a “denser” 3D print that may use more material. So really an optimized pricing formula should take into account not only the amount of materials, but also the density of the print.

Each machine also offers statistics upon which to calculate prices – but they frequently vary by manufacturer, machine and especially 3D printing process. Some processes involve multiple sets of materials. A full RGB color 3D printer might consume ink sets as well as thermoplastic material. If a job is using up all the yellow ink, then it should pay for same.

Some equipment also uses disposable adhesion sheets, which also must be accounted for – and these get quite complicated as sometimes they can be reused or partially used.

The more you get into 3D print pricing, the hairier it gets. Eventually I understood why some 3D print services simply took the cost of materials for a given print job and multiplied by “5” to arrive at the job fee. This seemed to be a very common approach. It’s easy to use, albeit not particularly accurate.

And all this is happens when you have full control over the pricing system, sometimes with modest systems like spreadsheets. What happens when you engage a 3D print job management system? Are you forced into using their concept of job pricing? What if it’s different than you expect or require?

This is something that every vendor of 3D print management software or services must contend with: allowing sufficient flexibility for clients to create pricing formulas that meet their needs.

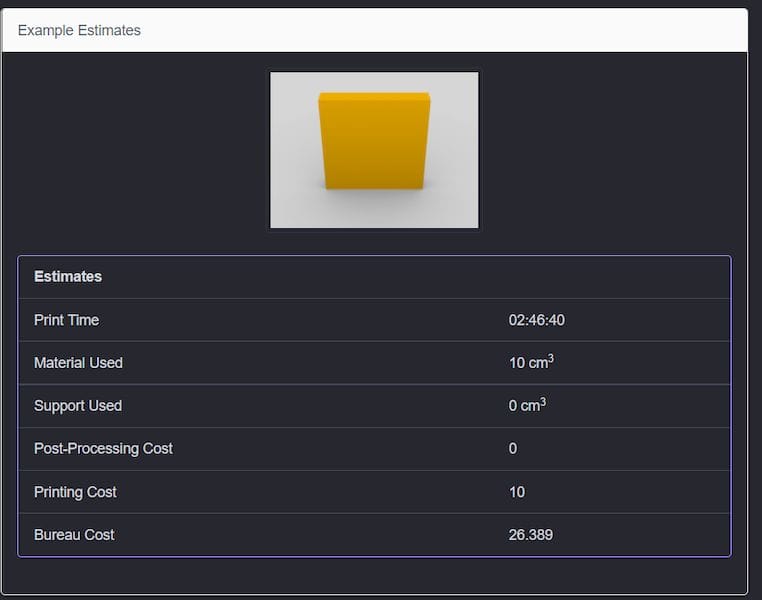

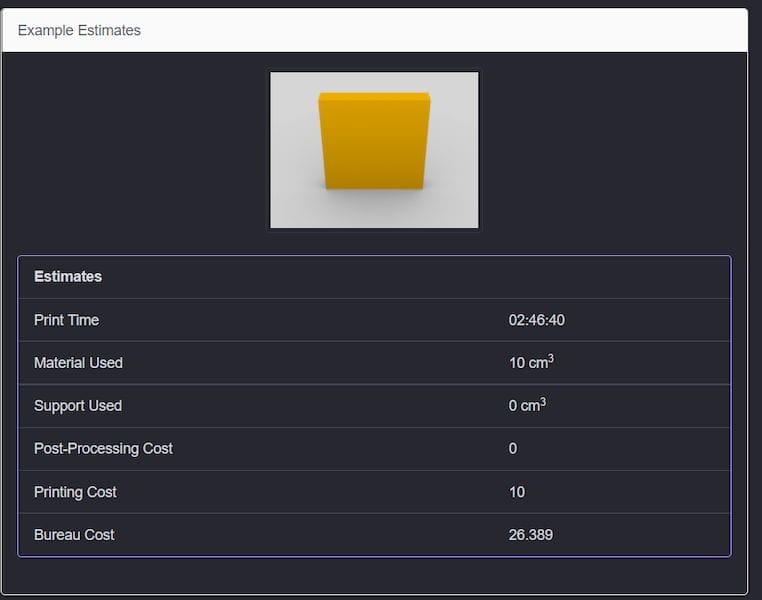

That appears to be the case, at least in the latest update from Authentise, whose “Manufacturing Execution System” now includes a formidable pricing system. Their “MES” now offers somewhat more complex pricing capabilities. They explain:

Users can now determine the price by time factors and material usage separately. Additionally, price factors like printer of choice or material can be weighed individually to drive the total cost of the order. Is machine time your key driver, or material use? Do you want to add a per-piece overhead?

It’s this kind of flexibility that will attract more people to using specific 3D print management systems, as you can imagine a prospective client dropping any system that cannot handle their pricing needs.

I suspect this is not the end of pricing system exploration for Authentise, as there are other dimensions of the problem yet to be explored. We will see, as these issues take time be identified, developed and deployed.

Via Authentise