Create It REAL just received a significant investment.

We thought it was time to catch up with the Danish company and spoke with Create It REAL chief Jeremie Pierre Gay, who explains their strategy and more about the investment.

Fabbaloo: Just so our new readers know, what does Create It REAL do?

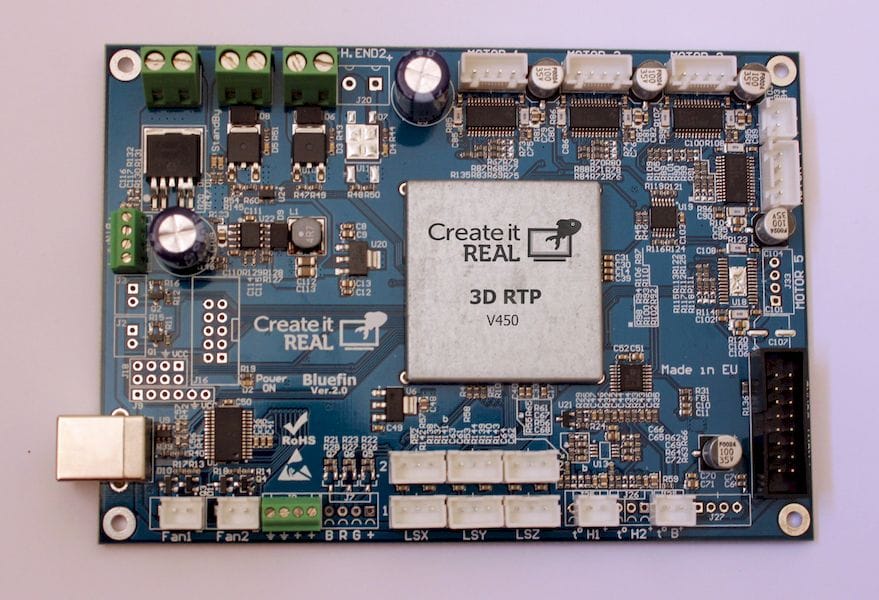

Jeremie Pierre Gay: Create it REAL is a Danish R&D center founded in 2009, specializing in 3D printing technologies. In 2013 we launched worldwide the first real-time processor dedicated to 3D printing. It allows FDM printers to reach speeds up to 5 times faster than current standards. We also developed our own slicer with unique features. We are selling our platform to 3D printer manufacturers and to large corporations for ad-hoc projects.

Fabbaloo: Speedy 3D printing is of interest to many in the industry; what companies have deployed your technology so far?

Jeremie Pierre Gay: Our customers are usually second time buyers when they have realized that 3D printing is very, very slow and they that could get same results in much less time. This is critical for companies as they can make several prototype iterations in a day instead of waiting until the next day when they print overnight. But speed is not everything, because for many customers, print quality is even more important. Seeing is believing, so I invite you to check our Instagram account to see our results.

Fabbaloo: Is use of your technology in a desktop 3D printer as simple as swapping in your control board? Can anyone do this? Or are there other considerations?

Jeremie Pierre Gay: For a 3D printer manufacturer, yes, it is easy to swap their boards with ours. Depending on how they built their machine, they may need some cable adaptors but that’s it. We provide a demo kit including the board, key cables and a 3.2” color touch screen. After that you need to create the printer settings, which you can do directly into our slicer software (much easier than upgrading a firmware).

The slicer is free and can be customized on demand to the manufacturer’s need or an end user target (beginner, advanced, expert modes). In the end you just need to double click on the configuration you want (Draft, Recommended, High-quality) and you are ready to print.

Fabbaloo: While it seems the company originally intended on speeding up 3D printers, you recently seem to have branched into a few other directions. What are they, and why go there?

Jeremie Pierre Gay: Four years ago speed was really a problem, which is why we focused on it. We fixed it so we could move forward on the next industry issue. Now, we believe the 3D printing market is blocked by the intellectual property rights.

Most brands do not release STL files because they know, like MP3’s back in the 90’s, that they will be copied and shared on Internet. So we want to build the “Spotify of 3D Printing”, where people will be able to 3D print without accessing the file itself.

They will be able to print as much as their subscription allows (it could be free by the way, it will depend on the brand business model and choice), but in any case, like on Spotify they do not need to access the file. This approach also guarantee no one altered it and settings used are the ones decided by the designer.

We can do this thanks to our real-time processor which can know decrypt files on the fly in the printer directly. We believe this is the safest approach as software based solutions will secure files up to your computer, but the files are clear between the computer and the 3D printer.

Many people will prefer to keep using free-to-use files and customize them if needed, while others will prefer to click and print a secured branded file. Thanks to our platform, they will be able to do both!

Fabbaloo: Are there additional future angles you are considering for leverage of your technology that differ from current uses?

Jeremie Pierre Gay: Our aim is to speed up 3D printing adoption and to make people more creative with the right tools. We believe 3D printing’s technical complexity is a key issue holding back this creativity. This is basically what we are trying to improve with REALvision (our own slicer), as we want to hide the complexity and automate most of the technical part (who needs to know what is an “extrusion rate” or an “overhang angle”?)

We believe end-users should be able to browse a web site or catalogue and “click to 3D print” any object they want. All the complex operations should be hidden and eventually they would not even need any piece of software. We will soon release our online slicer that will be the foundation to reach this goal. We are now in beta test with our current and future partners.

Fabbaloo: Recently you received a significant investment. Can you tell us the reasons for the investment, and who made it?

Jeremie Pierre Gay: R&D is a costly activity with long term goals, and R&D in 3D printing is even more difficult as things move so fast you need to find the right balance between short term issues and long term goals. The investment was led by the Danish Growth fund, a state investment fund helping Danish companies by providing capital and expertise and some private investors who share our vision and believe we are on the right track.

Fabbaloo: What is your intention for use of the funds?

Jeremie Pierre Gay: We will expand our team hiring software engineers to bring to life all our ideas. We also need to be more visible outside the 3D printing community so brands understand we already have the solution they are waiting for. Finally, we will also look to build long term partnerships with other companies in the industry to bring state of the art technologies faster to the market.

Fabbaloo: Where do you see Create It REAL in five years?

Jeremie Pierre Gay: We believe 3D printing is one of those technologies that can really change the world and bring creativity to all. Production tools in the past were in the hands of large companies or dedicated to some regions in the world, while now anybody with a good idea can make an impact. We hope in five years Create it REAL would have managed to fix all the issues we could identify and we helped to accelerate 3D printing adoption.

As a final word, let me offer to 3D printer manufacturers or innovators in the 3D printing field the possibility to contact us if they are willing to try our technology so we can boost the industry together.

Via Create It REAL