I have no idea how I missed this, but there is another free method for repairing broken 3D models.

Everyone using a 3D printer has certainly encountered bad 3D models. These are a result of the poor STL file format, which permits the definition of invalid solid 3D models. They may be fine for display on 2D screens, but when you attempt to print them there are problems. 3D printing transforms the virtual model into a physical object and it’s possible to define a geometry in STL that is impossible to produce in real life.

Thus you must use a repair tool to detect and fix these issues, which might include “holes”, stray segments, reversed facets and more.

Fortunately, there are a number of tools available for doing so. Some are standalone software tools, but an increasing number of them are online services of one kind or another. Some repair functions are bundled into other tools to ease the workflow – you might not have to jump out of one tool and then back in just to get a repair completed.

One of the more popular tools for 3D model repair has been NetFabb, now owned by Autodesk. Since the acquisition there has been a bit of confusion about the product, but as of today it still exists and can be used at no charge in standalone mode as “NetFabb Basic”.

What I did not realize was that there is a cloud-based version of NetFabb available to anyone, and it’s completely free of charge – and being in the cloud, there is no need for software installation.

Strangely, it’s not produced by Autodesk, but instead it’s from Microsoft, who have partnered with Autodesk (some years ago) to provide this service.

There’s not a big mystery to using it. You simply drag your 3D model into the window and hit “Repair”. The NetFabb system runs behind the scene in Microsoft’s Azure cloud quickly and your model is soon ready for download. You must hit “download” to download the result; I would have preferred it to automatically download it when done, but it’s only one more click.

The repairs seem good, but it’s a bit hard to tell as there is practically zero instrumentation about the processing. But a good result is a good result, and I’ll take it.

It’s very important to have multiple repair options available, because the different algorithms used by different repair tools can approach a given 3D model in different ways. It’s not uncommon for a repair to fail. In that case, you want to pull the next repair tool out of your toolbox and try that. And the next one, too, until you get your file properly repaired. Having another repair tool in your pocket is always a good thing.

There is a catch here, however.

The resulting repaired file is provided only in .3MF format, the slowly-being-adopted modern way to represent 3D models.

This is unsurprising, as both Autodesk and Microsoft are key members of the 3MF consortium.

It may be a bit strange to some who have grown up using only STL models, but 3MF is certainly a valid and superior way to represent 3D models. It’s an extensible format that will eventually be the de facto standard.

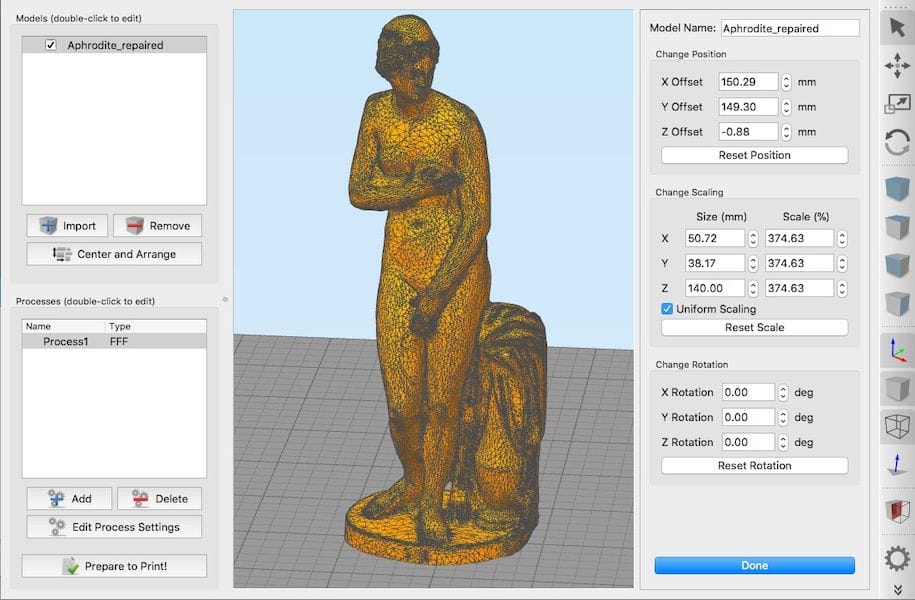

My thought was to convert the resulting 3MF file into a STL file, with, say MeshMixer, and proceed with the business of slicing and printing, but something interesting happened.

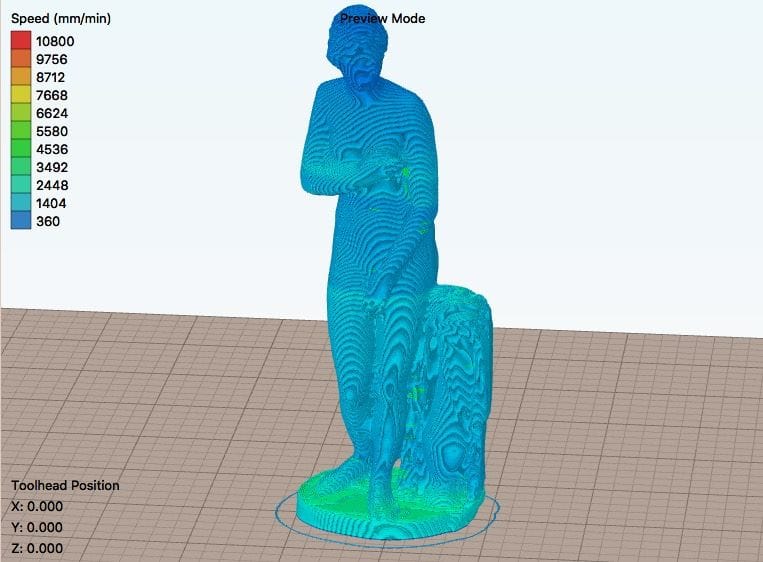

By chance I double-clicked on the 3MF file and I noticed that Simplify3D opened up the 3MF file directly. I could then slice the 3D model and print at will – without having to resort back to STL in any way.

It is a small thing, but to me it’s important: it’s evidence that 3MF has made sufficient inroads into various applications and utilities to enable accidental direct app to app use of 3MF without having to convert files.

If I had created the original file in 3MF I would have demonstrated an entire workflow that completely eliminated STL! Maybe I will do that next time.

You might want to bookmark this link if you haven’t already.

Via Microsoft