Sometimes it’s hard to figure out what might happen in the future, but perhaps we there is something now visible.

Having seen hundreds of 3D printers and their varied technologies over the past near-eleven years, I think I am now seeing what might be the very earliest chapter of an industry turnover.

Let me explain.

One way to look at the distant future is to imagine some mysterious, science-fiction style technology that doesn’t presently exist. We don’t know when that might happen, and we don’t exactly know what it is or may do for us, let alone how it may work.

But another way to imagine the future is to look at what is happening today and make some extrapolations. This may be more accurate, as there is a more solid foundation to base assumptions upon.

Major changes in technology don’t happen overnight; they happen slowly, right in front of everyone’s eyes. We don’t understand that a change is happening until it’s well underway. When we first see the “new thing” we often ridicule it as being inadequate for current use, even though it may improve gradually and eventually overtake current methods.

This is especially true if you begin to see multiple signals heading in a particular direction.

And this is the point I think I am at with the 3D printing industry.

Let’s put it another way: before our ubiquitous color inkjet 3D printers that seem to be everywhere these days, there was something called “dot matrix” printing. These machines used a primitive mechanical approach to printing characters by triggering ink ribbon impact of “dots” on a “matrix”.

The output was incredibly lousy by today’s standards, but it was actually quite useful at the time for many applications. Then somehow we switched over to inkjet 2D printing and everyone forgot about dot matrix devices. They were expensive at first, and people wondered about the costs, reliability, compatibility, software, usage and many other things. But it prevailed.

Today I am seeing the first evidence of what might be the technology for 3D printers of the future.

It’s called voxel-based 3D printing.

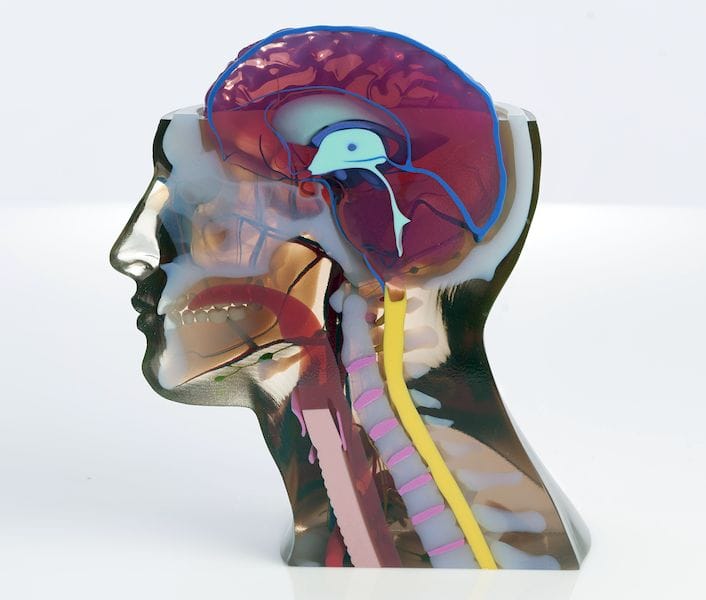

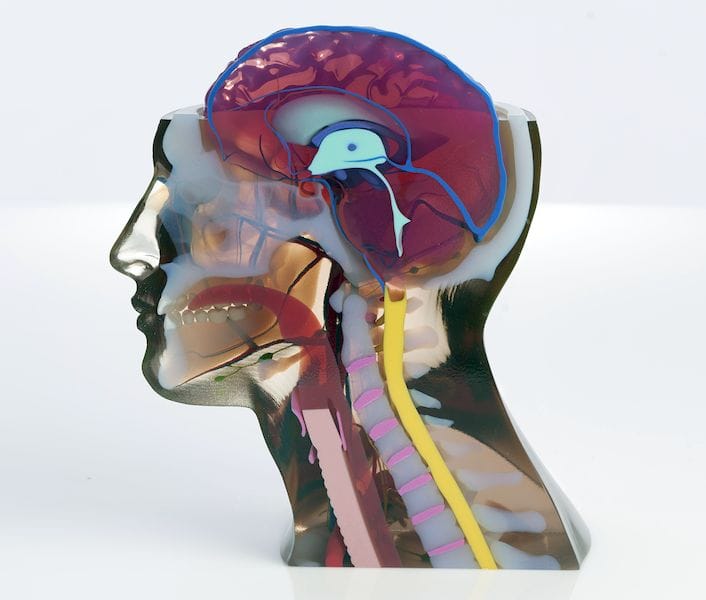

This capability means there is some direct level of control over literally every single voxel (a 3D pixel) of the output part. Not just the surface, but every voxel, even those buried deep inside the part.

“Control” in this case means the ability to change the material. It could be a soft or hard material. It could be a color or texture. It could be a material with different thermal properties. It could be an electrically conductive – or resistive material. Or anything we come up with in the future: radioactive, biological, liquid, explosive. Anything.

The first 3D printers that can do this type of 3D printing are now out. They are in a dreadfully primitive state in that the types of materials are extremely constrained. Perhaps colors only at this point. But this technology, as demonstrated in several proprietary processes, could be adapted for other materials as above.

Now I am certain you are thinking, “But no one wants color prints; we just make mono-material parts. This is all unnecessary!”

That’s correct. We just make mono-material parts (largely) today.

Why do we do that?

Because that’s what we’ve always done.

That’s what our machines allow us to do.

That’s what our software allows us to do.

That’s how we think of part design today.

But that’s all based on a past technology that enables only mono materials.

What if someone made software that could easily create highly complex 3D object designs in many materials?

What if you could buy 3D printers that could indeed use many different materials?

What if the ingenuity of such parts became an expectation?

What would a part printed on a mono-material non-voxel machine seem like in that kind of world? I suspect it would feel a lot like a dot-matrix print.

I think these things could indeed happen, and maybe sooner than you think.

I see this technology emerging from three companies today:

- HP, whose MJF technology can indeed control 3D prints voxel by voxel, and even at small production levels. So far they’ve used the tech only for color voxel control, but that’s just the beginning.

- Stratasys, whose PolyJet technology was adapted to produce full color prints on their J750 device, but could theoretically introduce a number of different materials in the future.

- Rize, whose inkjet technology also promises to enable voxel level control suitable for embedded circuitry, full color and more.

Since the technology from these companies emerged, I have begun to sense a slight movement away from STL file format – because it does not support voxel-level control, at least for these machines. I’ve also seen a couple of software ventures attempting to enable true multi-material voxel-level 3D design.

If these companies, and others who implement similar complementary technologies, continue to expand their capabilities, we may just end up with that future world described above.

This is the beginning of a huge industry switchover, one that may take many years to become visible.