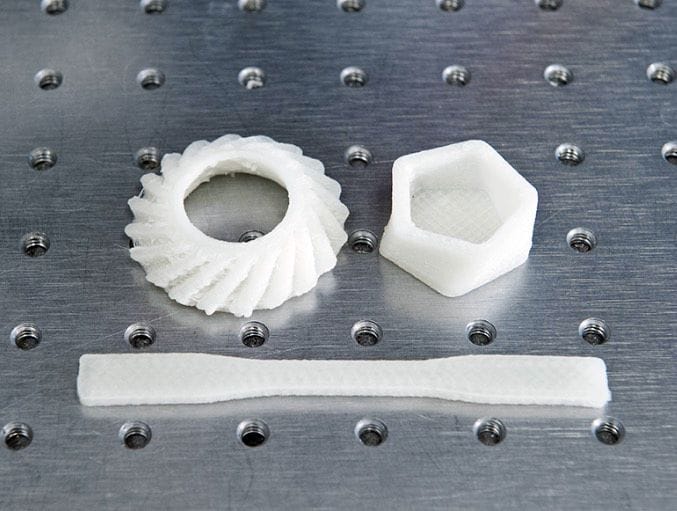

![3D prints made from cellulose [Source: MIT]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a12378b48.jpg)

Researchers at MIT have been working on a practical method of 3D printing cellulose.

Cellulose is a bio-material that’s common in nature. It’s extremely common, and you encounter some everyday. Wikipedia writes:

”Cellulose is an important structural component of the primary cell wall of green plants, many forms of algae and the oomycetes. Some species of bacteria secrete it to form biofilms. Cellulose is the most abundant organic polymer on Earth. The cellulose content of cotton fiber is 90%, that of wood is 40–50%, and that of dried hemp is approximately 57%.”

The commonality of cellulose would suggest that if used as a 3D printing material, it could be quite inexpensive, as compared to many of the currently popular materials, some of which are derived from unsustainable sources like petroleum.

Cellulose also has a number of interesting chemical and engineering properties, making it even more attractive for use as a 3D printing material. And as an organic material, it is entirely biodegradable.

Why haven’t 3D printer operators used cellulose already? It seems it has a rather challenging problem to overcome. As you heat it up for extrusion the material very rapidly degrades and becomes unusable.

But now MIT researchers have found a fascinating method of actually 3D printing with cellulose. Their process involves multiple steps, and starts with a material known as cellulose acetate, a material formed by exposing cellulose to acetic anhydride to form a type of salt.

The cellulose acetate is mixed with acetone in just the right proportion to form a viscous slurry that is suitable for extrusion using a type of paste extruder mechanism.

![Cellulose 3D printing concept [Source: MIT]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a123dea99.jpg)

As the extrusion proceeds, the acetone naturally evaporates, leaving a print made of solid cellulose acetate. This isn’t quite cellulose, so the print is then soaked in a bath of sodium hydroxide which removes the acetate and leaves a pure cellulose object.

The researchers found that their process delivers objects with very strong bonding between layers, said to be higher than is typically found in extrusion-based 3D printers. They also found it relatively easy to mix in different substances to obtain different properties. For example, they added an antimicrobial dye to the mix and printed self-sterilizing tweezers. This bodes well for widely varied uses of cellulose 3D printing in the future.

![Antibacterial tweezers 3D printed in cellulose material [Source: MIT]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a12430e3a.jpg)

For now this is merely research and is not a product. My main question about this invention is the cost. The original intent was to leverage the commonality and thus inexpensive nature of widespread cellulose, but will that equation still hold after requiring acetates, acetone and sodium hydroxide? The multiple stages of this process may negate the expected cost savings.

If the researchers can verify the cost and functional utility of their process, then we may see it appear as a true commercial product in the future.

Via MIT

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.