![The LumiFold TB portable high-resolution desktop 3D printer [Source: Lumi Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a5a65d343.jpg)

Lumi Industries is set to release a new desktop 3D printer.

The Italian company has been on these pages before, specifically in 2015, where we reported on their development of a resin 3D printer that used the (at the time) unusual concept of a stock LED/LCD tablet as the light engine. Previously they had developed a more or less standard resin 3D printer.

But that was 2015, and today is late 2018. Where the heck has this printer been? Now we find out.

CEO Davide Marin explains what happened:

“The New Lumifold disruptive mechanical system, allowing the 3D printer to be very thin and totally space-saving when off and closed, but to grow in height, when on and printing, was first launched in 2015.

We have been working on it since then, redefining the system to reach a professional accuracy level up to 25 microns on Z axys, developing a powerful electronic board without compromising the minimum size, finding a functional, minimal but also eye catching and cool aesthetic design.

The system can be applied to different 3D printing technologies being them filaments or different type of resin techniques (SLA, DLP, LCD).”

Their goal is to produce an extremely tiny 3D printer that is low cost. The cost factor is achieved by eliminating the light engine component entirely and requiring the operator to provide a small tablet (in this case an Apple iPad Mini 3 or 4), which are often in the possession of the operator anyway.

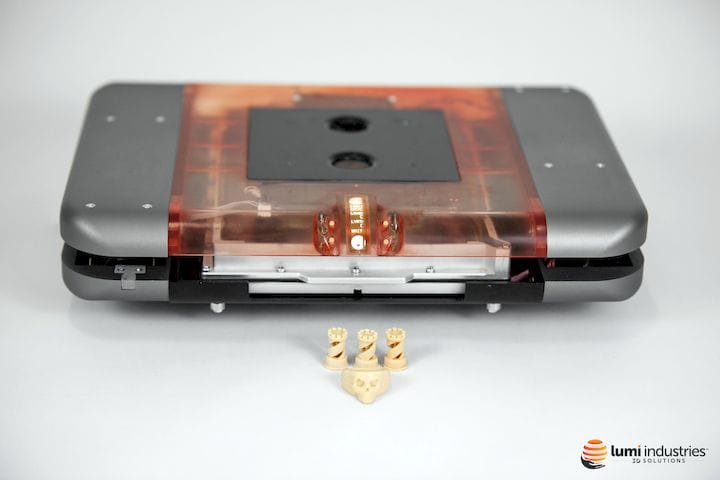

![Sample 3D prints from the LumiFold TB appear to be of excellent quality [Source: Lumi Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a5a6b9a79.jpg)

The company’s software on the tablet produces appropriate light patterns that shine through the bottom of the resin tank and solidify the photopolymer, layer by layer. They explain that they don’t use standard 3D printing resin because it’s optimized for UV light wavelengths, while tablets don’t produce those frequencies so well. Instead they have a modified photopolymer resin that reacts better to the light produced by the tablets. However, it takes a bit longer to solidify, which is why most manufacturers prefer the UV-style resins.

The LumiFold TB, as it is now called, includes a 100 x 100 x 100 mm build volume, which is small but appropriate for a high detail 3D printer like this. They boast of a XY voxel size of only 0.078mm and a layer size of 0.025mm, which should produce excellent quality prints.

There is no wiring required between the tablet and the printer itself, as this is all done through a wireless bluetooth connection. This should make installation extremely easy.

But the most fascinating feature of the LumiFold TB is that it is literally foldable. At top it doesn’t really look like a 3D printer at all; it appears to be more of a “tab” (hence the name “TB”).

![The LumiFold TB portable desktop 3D printer unfolded [Source: Lumi Industries]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a5a715f18.jpg)

But here we see the device unfolded and ready for action. The mechanism lifts open the print volume and the resin tank is at the bottom. The tablet is placed underneath to provide the light engine source. It’s certainly highly portable.

One question I have is regarding the “daylight” sensitive photopolymer resin. As the machine does not appear to have “shades”, is it recommended to 3D print in the dark? I suspect leaving this machine open on the windowsill in the sun would be a bad idea.

Another question is the price. As of this writing Lumi Industries does not yet have an official price for the machine, but they do intend on showing it at the upcoming Rome Makerfaire where more details may be forthcoming.

Via Lumi Industries

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.