![Mitsubishi’s concept for a new metal 3D printer [Source: Mitsubishi]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a3d085c1a.jpg)

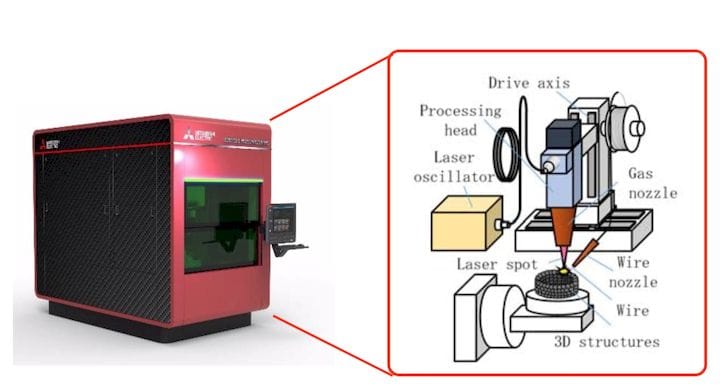

Mitsubishi Electric announced a new metal 3D printer.

The company, part of the gigantic Mitsubishi conglomerate, produces a wide variety of industrial equipment, ranging from automotive, to factory, to semiconductors and even space-based systems. But to our knowledge they had not yet announced a 3D printer.

But now they have.

The as-yet-unnamed machine, likely an early prototype, is set to be shown to the public at an industrial trade show in Japan next month. However, they say they will not release a commercial version for purchase until as late as March 2021, some 2.5 years from now.

Mitsubishi is undertaking an interesting 3D printing process with the new machine, which uses a direct energy deposition method. We’ve seen this form of metal 3D printing before: it involves feeding a metal, either powder or wire, towards a moving energy source. The metal is briefly melted and deposited on a surface, where it quickly solidifies. Moving the deposit toolhead in three dimensions gradually builds up a complete object.

But there are some interesting differences in this approach, making their process attractive.

The machine will use common welding wire as its material. This has two key advantages over most other metal 3D printing processes.

First, the cost of the material will be rock-bottom low. Welding wire is a very inexpensive material that is commonly available worldwide at commodity pricing levels. It’s also available in a wide variety of different materials, many of which might be appropriate for 3D printing.

Secondly, the material is wire, not powder. 3D printing processes using powder are subject to all kinds of constraints and extra process steps. Powder users must continually store their very expensive 3D printing metal powder in airtight containers to prevent immediate oxidation. They must also sieve unused powder after printing to pick out splatter that might corrupt future prints – again doing all this in an airtight manner. They must also do all this work in air-controlled environments as the powder is both toxic and sometimes explosive, leading to considerable expense just to set up the 3D print workshop.

These are not the only advantages the new Mitsubishi process has. They seem to have implemented some type of sophisticated technology on the deposition tool.

The energy source is a laser, which we’ve seen before. However, Mitsubishi is using a pulsed laser. This enables them to use a voxel-by-voxel approach to 3D printing the metal, rather than a continuous melt as other similar processes might use.

Their “Dot Forming” approach is enhanced by their ability to control the laser power with precision, as well as controlling the shield gas at the point of deposition. The shield gas is a flow of gas surrounding the nozzle that helps to contain the melting environment. If they can control this zone accurately, they may be able to increase part quality significantly.

It seems that they may be able to do this, judging by the images of prints they’ve tested:

![Samples from metal 3D printers [Source: Mitsubishi]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a3d0e3daf.jpg)

Here we see a sample of their Dot Forming print process on the right, with a sample on the left from a continuous laser process (they seem to call it “consecutive” instead of “continuous”, perhaps due to a translation error).

This jives with my experience in examining continuously fed metal 3D prints, which tend to be a bit sloppy on quality. In fact, several such systems also include a matched CNC mill that can quickly clean up the print by producing smooth finished surfaces. But Mitsubishi’s process might not require that step, making it less expensive.

We won’t know much more about this process until they release more in a year. Or two.

Via Mitsubishi

Aerosint and Aconity have proven out their work in multi-metal powder deposition 3D printing.