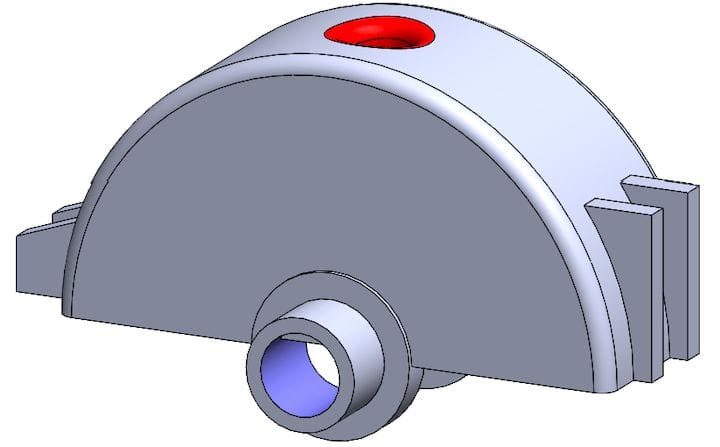

![A redesigned replacement part [Source: SOLIDWORKS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a5074974e.jpg)

Robert Maldonado undertook a challenging job to repair a broken toy using 3D printing and CAD, illustrating how challenging it can be.

The application engineer at DesignPoint had obtained a more than well-used ancient Guitar Hero video game at a thrift store, in a pique of nostalgia for his youthful experiences.

However, he discovered the guitar itself was broken, as the “whammy bar” was inoperative. I’m not at all certain what a “whammy bar” does, but apparently it’s a critical component to Guitar Hero. (Editor’s note: only if you want a good score!)

Maldonado discovered that the bar’s internal attachment had worn away and broken, as you can see in his short video:

This is a scenario encountered far too often by consumers: a relatively complex item has irrevocably broken in a way that is seemingly impossible to repair on one’s own.

Maldonado took apart the guitar and discovered that indeed the spring tab on the interface connector had broken away. He also noted some aspects of the original design that contributed to the failure.

At this point in the diagnosis, most people would simply give up and toss the guitar in the recycling bin and purchase another unit, as repair parts for such a device are near impossible to find without cannibalizing another device. However, Maldonado is a design engineer with CAD design skills, so the outcome turned out quite differently.

![Improved part design using fillets [Source: SOLIDWORKS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a507ad7ab.jpg)

He was able to redesign a replacement part by measuring the original’s dimensions with calipers and forming a similar geometry in SOLIDWORKS. Maldonado even incorporated several minor fixes into the new design that should make the new part much stronger. He notes, however:

“I changed the cantilever design to a doubly-supported overhanging design, which should give it better resistance to the bending moment that it experiences during use. NOTE: this would make it very difficult to mold without the use of side cores, but since we are 3D printing, we have that design flexibility!”

So perhaps the original design did not have the required strength due to its manner of manufacture? In any case, Maldonado successfully 3D printed a version of the new design, but found the mounting hole to be too small. This is a very common occurrence as 3D printers often overflow holes when extruding and make them smaller than intended.

![The 3D printed repair part installed in the aging Guitar Hero [Source: SOLIDWORKS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a508000f4.jpg)

But after a quick hole resizing, a proper part was produced, and he was able to successfully restore the part to full operation. He even tidied up the exterior of the guitar to make it appear as good as new, which it was.

All of this was apparently completed within a single day, quite an impressive feat of repair.

![Before and after images of the used Guitar Hero [Source: SOLIDWORKS]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a508477d3.jpg)

My thought is this: I wish many more people were able to accomplish this repair, but the truth is that even though 3D print technology is reasonably accessible in most locations these days, the skills and tools to perform the design work are not. For many situations, paying a 3D CAD designer to redevelop a replacement part would far exceed the costs of simply replacing the device completely.

The biggest barrier to 3D printing for most people is the design step, not the printing itself.

Via SOLIDWORKS Tech Blog

Tech Soft 3D, a producer of powerful toolkits for CAD/CAM applications, received significant funding.