Your desktop 3D printer is likely far more well equipped than early machines, but are there things to make it even better?

I’ve observed the progression in capability of the first extrusion-based desktop 3D printers in 2008 all the way to today and it is startling the amount of functional and quality improvements that have taken place. Today’s machines are often highly reliable, produce very good quality results and are often inexpensive, too.

But that wasn’t the case years ago. I recall when the idea of motion axis end stops was a feature. However, we’re long past those days, as each year manufacturers manage to pack an increasing number of amazing features into current 3D printers.

Today we see machines that include a number of defacto standard features, such as a touch screen for control, heated print surface and much more. These all make using the machine more reliable and easy, but is there more you can do?

There is. Here are several add-ons you might consider applying to your desktop 3D printer to improve your 3D printing experience.

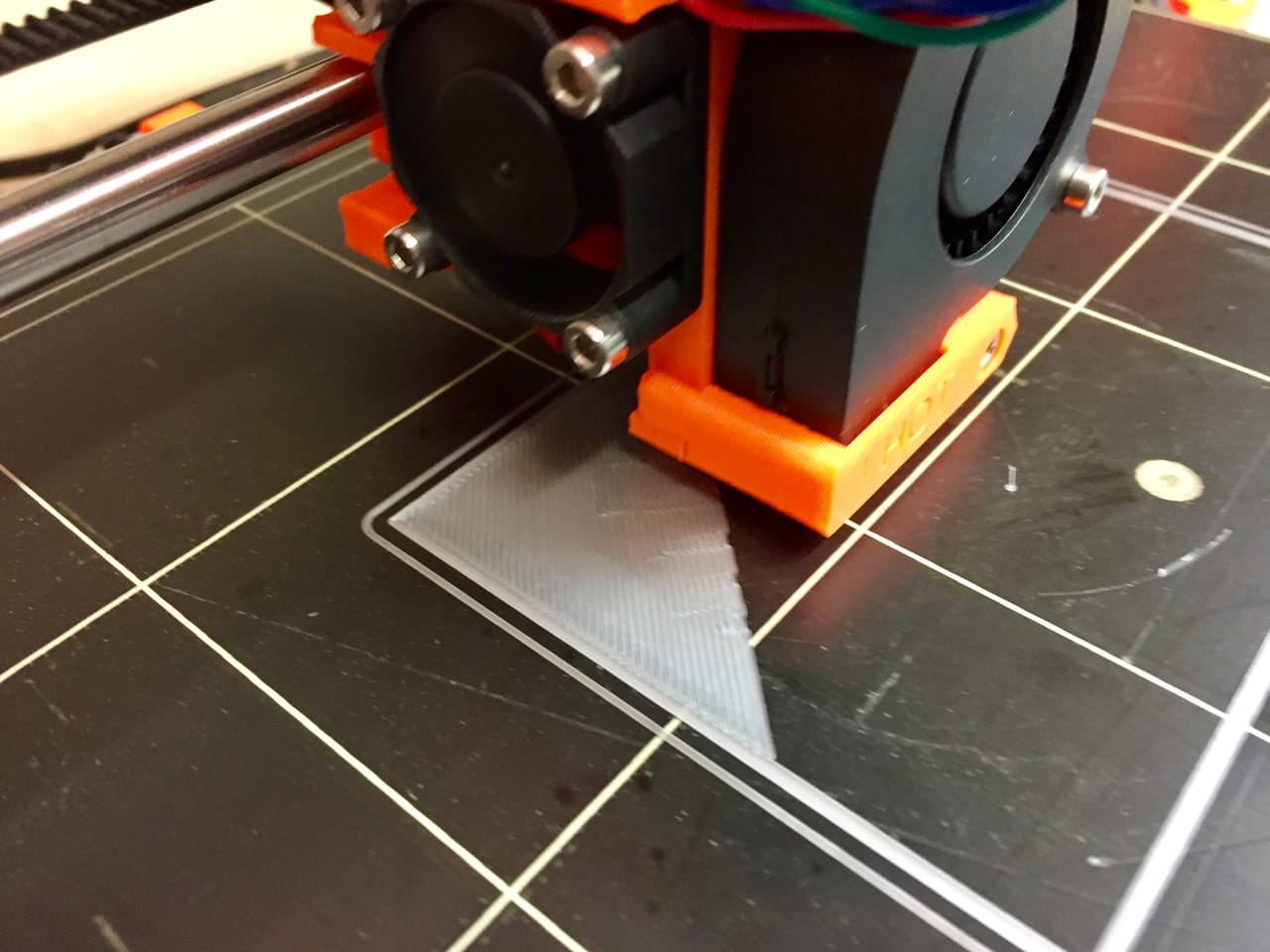

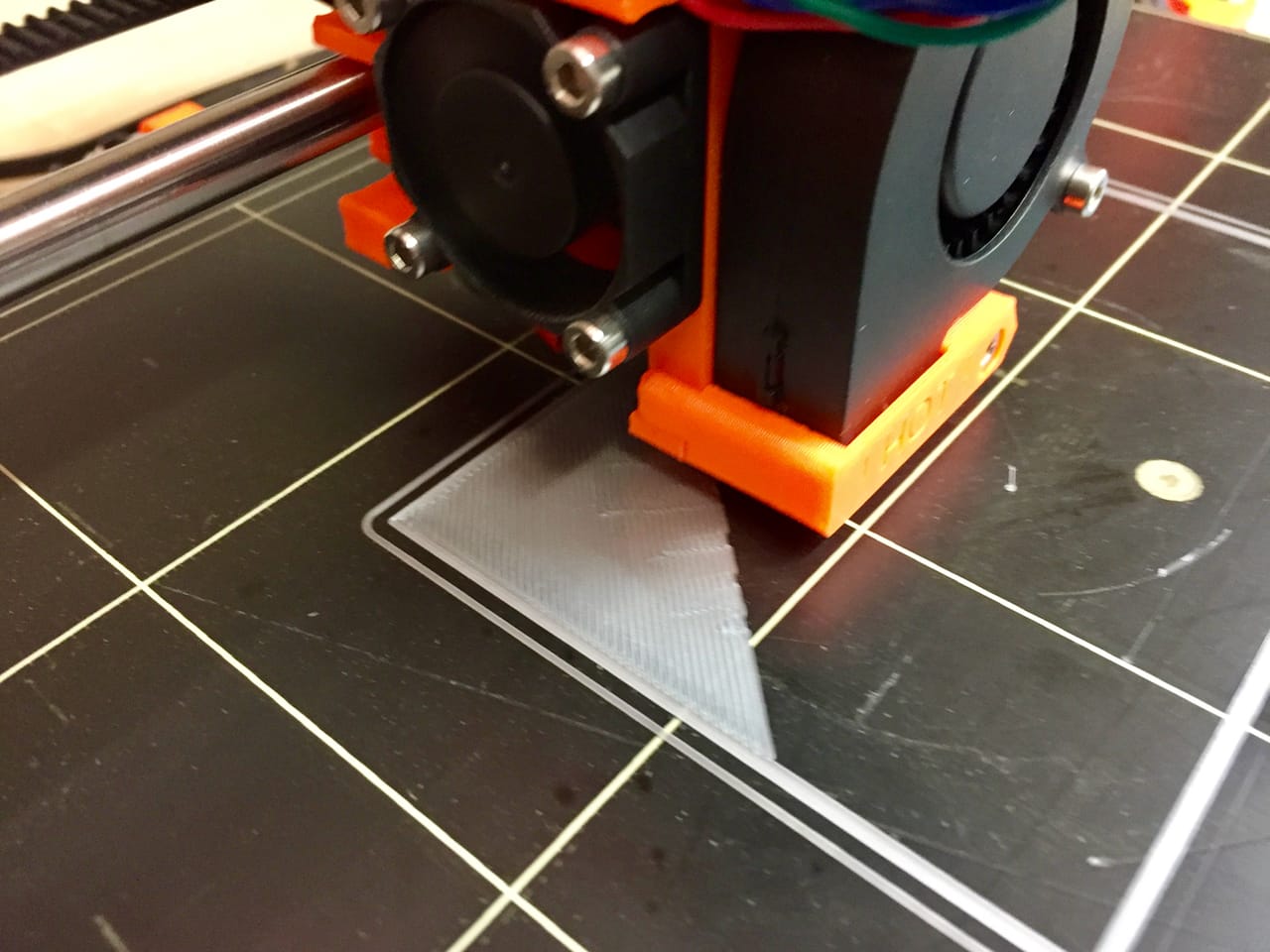

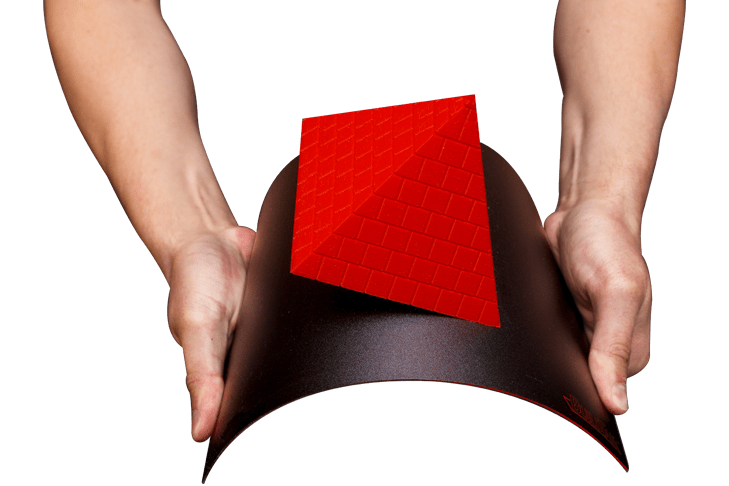

Sophisticated Adhesion System: Many desktop 3D printers offer stock, fixed print plates on which you must apply glue or other substances to afford proper adhesion during the printing process. One highly productive upgrade is to acquire a professionally designed adhesion system, which can substitute for your existing print surface.

A good option here could be one of the print plates from PRINTinZ or BuildTAK, who produce a series of different adhesion solutions. An increasingly popular system is a magnetically attached spring steel flexible plate with adhesion surface. These permit you to easily remove the plate from the 3D printer and twist for easy release.

Cloud-based Control: Most desktop 3D printers are rather dumb. That is, they have a rudimentary control panel that simply runs the machine locally. Even many of the visually fancy touch screens typically do just this and not much else. But a powerful upgrade can be a set-top box attached to the 3D printer via USB can add a number of extremely useful functions.

A set-top box can connect to the internet properly, and provide a wealth of function, particularly if combined with a cloud system. Essentially, this means remote control of your device, potentially video monitoring via internet, mobile app access, and often the ability to access a stored library of 3D models and sliced print jobs.

There are plenty of options for this upgrade, including the open source OctoPrint, as well as commercial options such as 3DPrinterOS, AstroPrint and others.

Effective Spool Holder: I’ve yet to see a stock desktop 3D printer with an outstanding spool holder, at least for machines consuming generic 3D printer filament. Most often you end up building your own, which can be fun as you’re 3D printing the parts.

Nevertheless, a custom-built spool holder will permit you to use all sizes of spools, even larger capacity versions. It can also reduce filament path friction and ease spool rotation, which can affect print quality.

Filament Dryer: Not many 3D printer operators have one of these, but a filament dryer is an accessory device in which you store filament. The idea is to pull the moisture out of the filament before you print it, which can increase the quality of prints significantly in some cases. This is particularly important in humid environments.

It’s also a way to resurrect old filament that’s been lying around exposed to the environment, so it may be a way to pay for itself if the filament dryer can restore filament you’d otherwise throw away.

Advanced Slicing: Every 3D printer is accompanied by a software GCODE slicing system recommended by the manufacturer. In most cases the software is tuned to work best with that particular device, but many of these systems don’t provide more advanced flexibility in options to attempt complex 3D prints.

A good option is to splurge on a third party software slicing system, and there’s one that is most notable: Simplify3D. It’s a paid product, but I’ve found it works with almost all desktop 3D printers, is very easy to use, provides as much or as few advanced features as you’d like to see, and quite often the print quality is superior to the stock slicing software that came with the machine.

Color Upgrade: Tired of 3D printing in a single color? It’s possible to change your machine into a multi-color machine by using the Palette. It’s another accessory device that, on the fly, cuts and pastes multiple filaments into a single strand that feeds into your desktop 3D printer.

The idea is to “change” colors during printing by segmenting the input filament into the correct sequence of color changes. It’s a very interesting idea and can literally make your mono printer a color printer.

Composite Materials Upgrade: You may have heard of “metal” 3D printer filaments, with some folks 3D printing steel, copper, brass, carbon fiber or other seemingly exotic materials. While it’s possible to simply buy these filaments and attempt to 3D print them, that’s not a good idea.

The problem is that virtually all desktop 3D printers default to a brass hot end nozzle. Brass as a material, is softer than many of these composite materials, which are powdered and mixed into a standard polymer binder. As they pass through the softer brass nozzle, they gradually wear it away, compromising your 3D printer’s ability to precisely deposit material.

The upgrade recommendation here is to swap out your brass nozzle for a much harder one. Stainless steel nozzles are very easy to install and can handle most of the composite materials, but it’s also possible to get even stronger nozzles made from tungsten, for example.

The bottom line here is that it is quite possible to supercharge your existing 3D printer with the addition of some well-tested third party equipment and services. What upgrade might you consider?