There seems to be lot of news surrounding MIT’s announcement of a color changing 3D printing technology, but how could you use it?

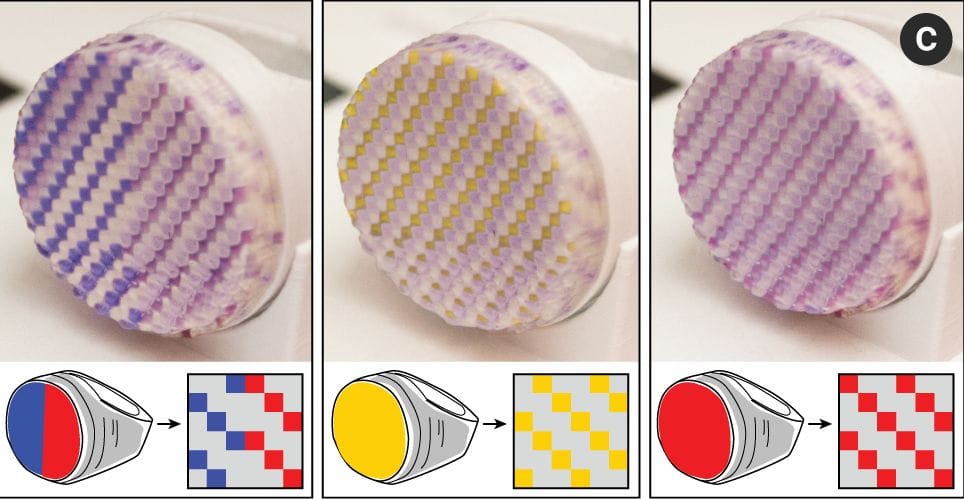

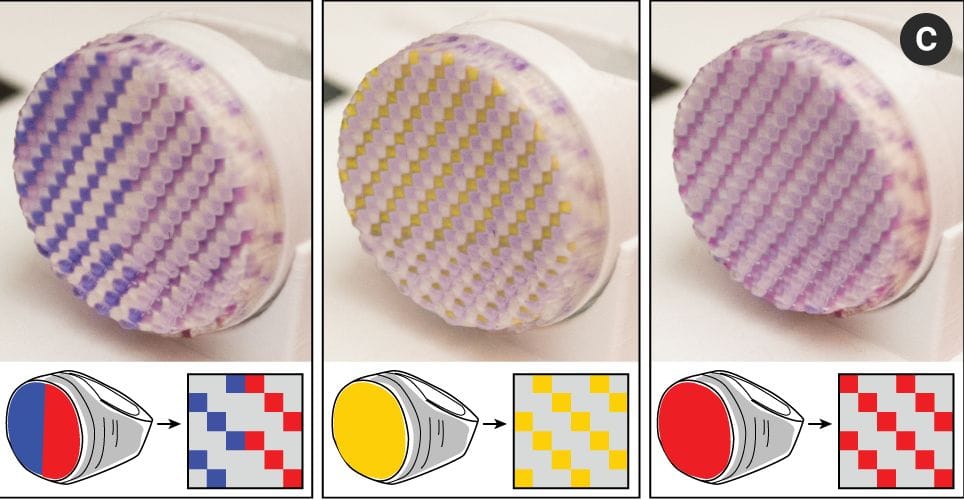

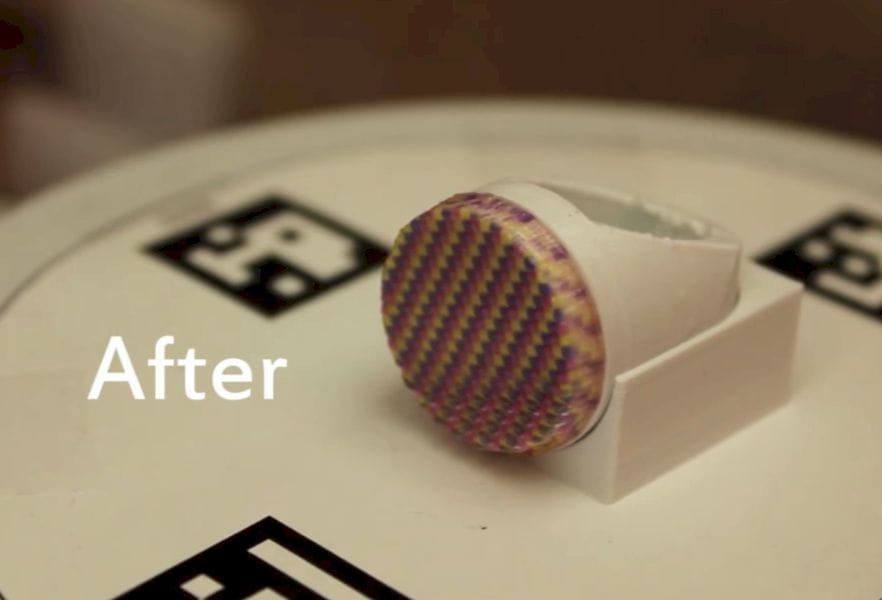

The researchers developed a series of inks that are able to change color upon exposure to UV light. Then the issue was to somehow incorporate this into a 3D printing system through which one could presumably change an object’s surface color and texture, for example.

This is all very interesting, but I don’t see how this can be of practical use yet. The researchers explain that theoretically you could 3D print a much finer pixel pattern to thus render more complex images.

That is almost certainly true, but there are a couple of problems I see with this approach.

First, the illumination pattern shown in the video is always towards a flat surface. This 2D pattern then easily illuminates the required pixels, but I’m wondering whether this could be made into a 3D process?

To do so, you’d have to somehow control the pixel illumination very precisely and at various angles. I think to have this work properly with a true 3D printed object, you’d have to have software that can first deploy a usable pixel pattern on the entire surface of the object.

Then the fun part starts. You’d have to build a special illumination system that somehow tracks the rotation of the 3D printed object in front of the light source and precisely rotates it. While rotating, the light pattern must rapidly change to adapt to the surface exposed at each orientation. In this way you could illuminate the surface fully on a 3D object. Worse, the “color curing” process apparently take several minutes to complete, so a full object rotation and coloring session could be quite lengthy.

If such a system could be created, it might mean a different workflow for 3D printing:

- Design the 3D shape

- Design the surface color and texture

- Generate GCODE to print appropriate ink voxels

- Print the object in otherwise normal material

- Place the print into the “coloring chamber”

- “Color cure” the print as described above

Somehow I feel this would be rather difficult to build and operate reliably.

There is a second problem with the process: it’s temporary. Yes, the UV light does “permanently” color the inks, but when exposed to UV light the inks return to normal transparency. And that other UV light would be what you receive outdoors.

This suggests that any object colored with this process would quickly become transparent again, severely limiting the outdoor applications of the process.

There is another possibility: perhaps an object can be coated with a transparent UV blocking glaze? This might mitigate the re-transparency effect. This would add another step to the workflow above.

As you might expect, this is only research at this stage, and obviously requires considerable work to transform it into a useful product that is salable. But it is a very colorful solution.

One thing I’d change, however, is the name they’ve chosen for this process: “ColorFab”, which is dangerously close to colorFabb, makers of fine 3D printable materials.

Via MIT