I had occasion to 3D print an aircraft 3D model and found a common problem.

As a present, I need to 3D print an aircraft and I selected the Boeing 737. There are plenty of very good 3D models of this particular aircraft, so it should have been easy to produce a 3D model.

However, 3D models of aircraft pose a bit of a challenge because they do not have a flat bottom that can easily adhere to the print bed. This implies you must use copious amounts of support structures to 3D print the aircraft.

Unfortunately, use of many supports would inevitably compromise the surface quality of the bottom surfaces of the print, and that’s not desirable.

Another approach is to section the aircraft into more easily 3D printable segments that don’t require as much – or preferably any – support structures. I found a 3D model in Thingiverse that is organized in just this way: the Boeing 737-300 by Thingiverse contributor Zydac.

This particular model is smartly chopped into very easily 3D printable segments, and I don’t think I used support on any of the components. Just print and glue together.

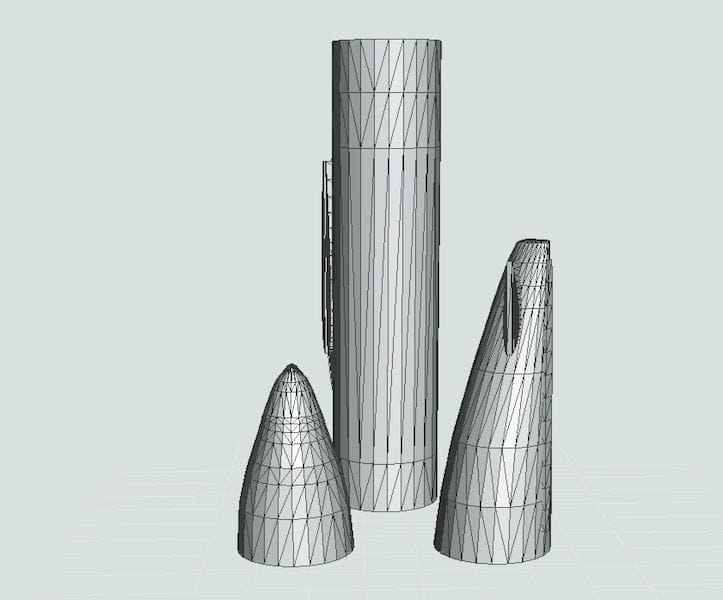

But that’s when the problems started. Take a look at the fuselage sections here:

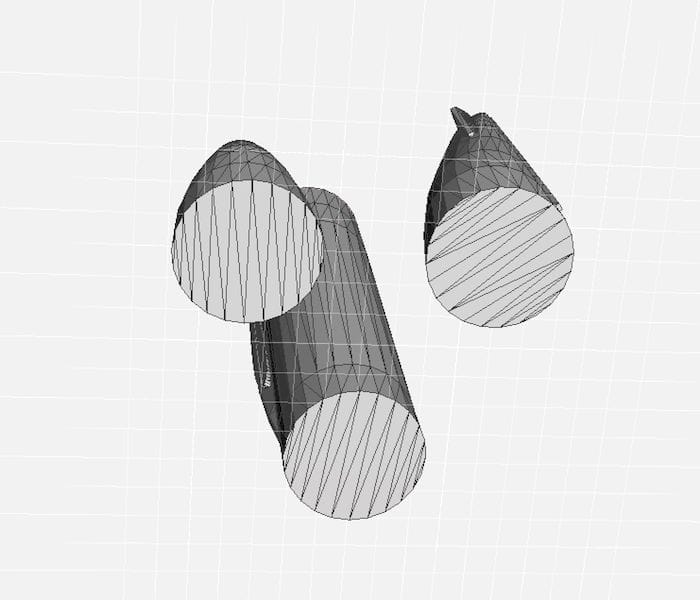

They appear quite suitable, but then look at the bottom of the these components:

They are entirely flat. That’s great for 3D printing them, but it gets far more tricky when attempting to glue the parts together afterwards: There is no easy way to properly align the parts because the surfaces are flat. Worse, there is no easy way to clamp these surfaces together during glue drying due to the geometry of these parts.

For me, it turned out to be “do the best you can by eye” approach, and it turned out not too badly.

But this terrific 3D model could have been made a bit better by adding a couple of lugs and holes to enable easy part alignment.

To add such features, it would take a bit of effort to create an add-on lump and corresponding hole in the mated part. But many designers, at least on Thingiverse, don’t bother to do so.

Would it be possible to automate such a process in an effort to increase make it easy for designers? It seems like something one could do with OpenSCAD, the programmatic 3D modeling language. Just pop in a 3D model, cut and add the attachment features.

This led to me a very interesting post on HackaDay, where writer Al Williams seems to have done something very similar, although he’s attacking the problem of segmentation for avoiding support structures.

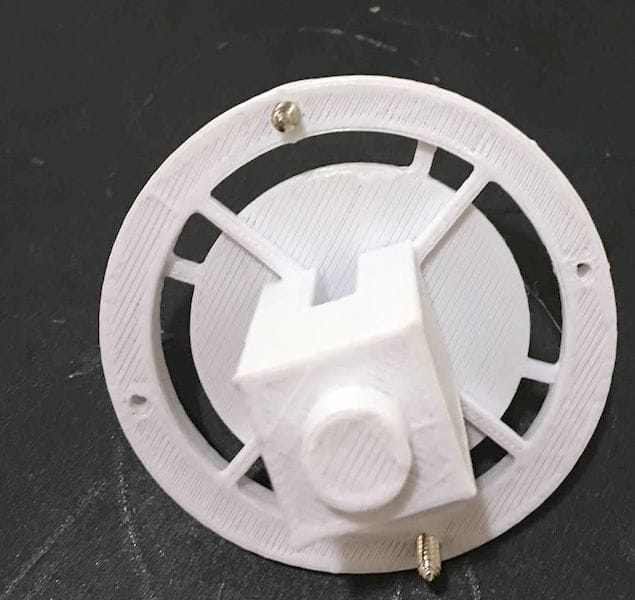

William’s approach involves using OpenSCAD to cut the 3D model and then adding a circular flange around the segment, which can then be perfectly aligned with a similar flange surrounding a corresponding part.

The flange will not only align the parts perfectly in X and Y axes, but also be able to hold the parts fast in the Z axis during gluing. After gluing, the flanges can be removed and discarded, leaving only a small deformation where the flange had been attached.

It seems like a great idea that could be attempted on many types of parts, although there are certainly some situations where this won’t work. But for those with a single-material 3D printer, it’s a great solution.

Williams has made the OpenSCAD code available to the public at his GitHub site, where you can download and give this approach a test.

Either that or get yourself a dual extrusion 3D printer and use water soluble support material!