I’m looking at an interesting experiment to provide a security mechanism for 3D prints.

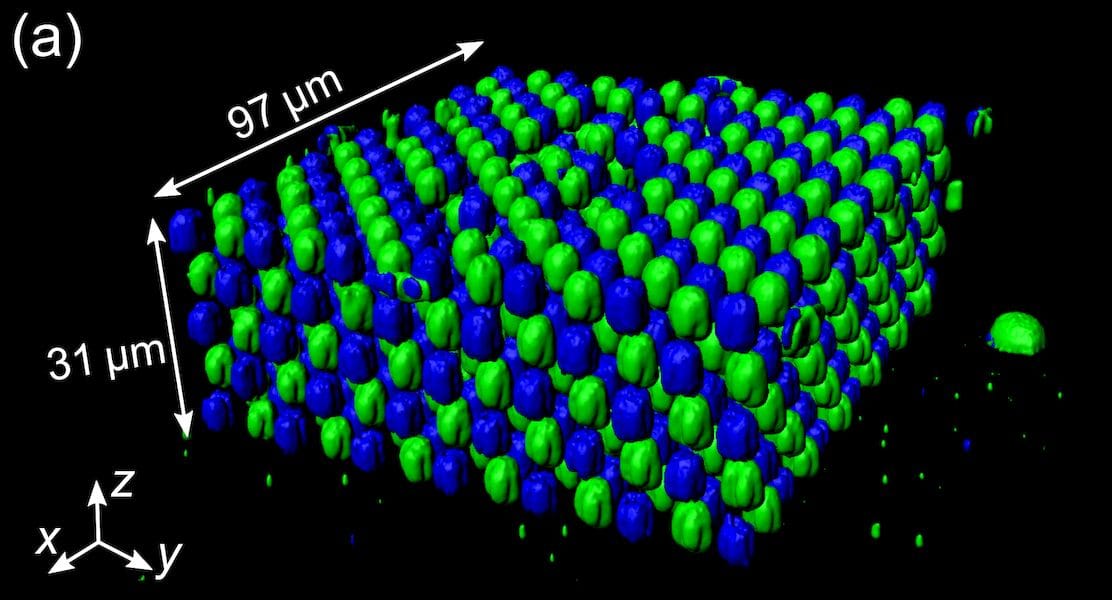

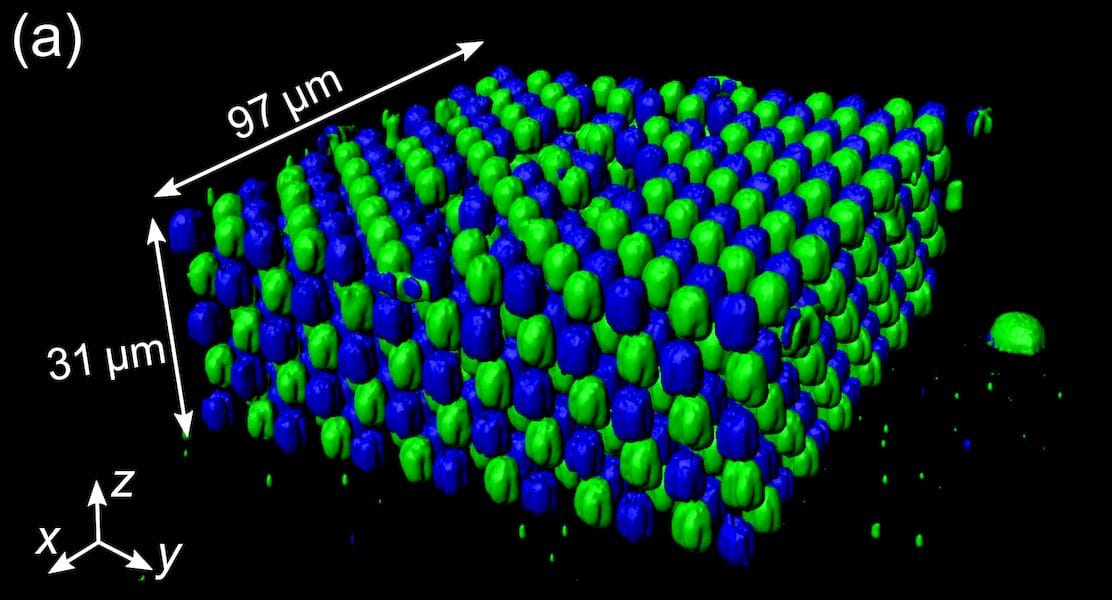

The project, by the Karlsruhe Institute of Technology and ZEISS attempted to 3D print a 3D matrix of fluorescent particles at a very small scale using 3D printing equipment from Nanoscribe.

The illustration above shows what was attempted: produce a 100 micrometer matrix containing a mix of three particle types, with two being differently colored – and fluorescent.

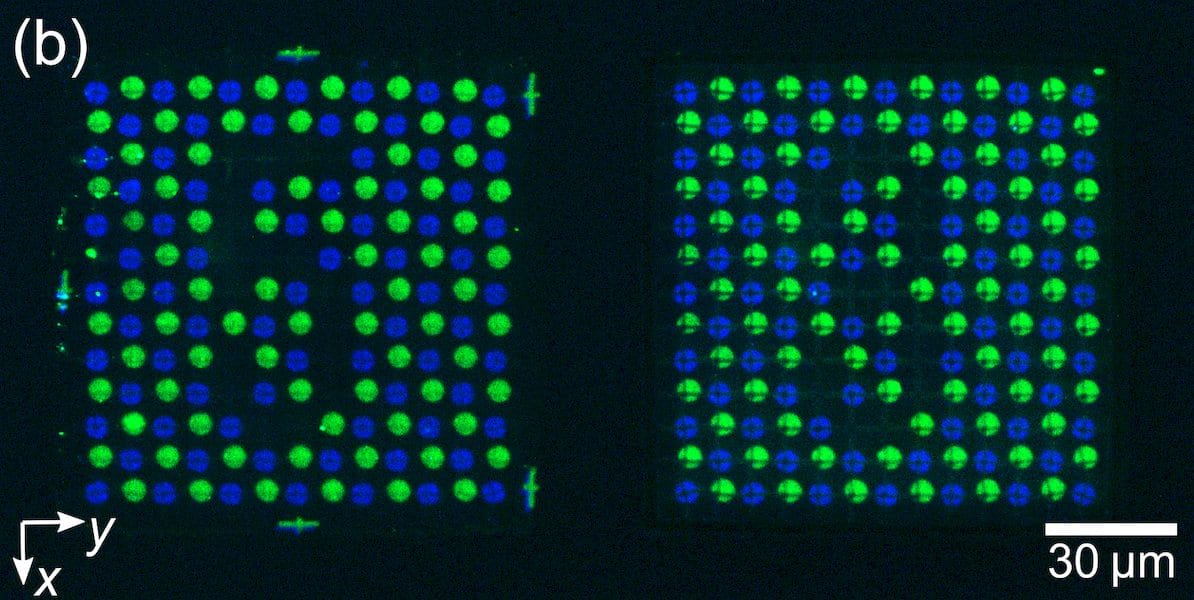

The matrix was designed to hold a serial number, which could be used for security purposes. In the example above, they encoded “53” as the number. In a 3D print manufacturing scenario, it would be possible to print a different serial number on each print, making them uniquely identifiable.

The resulting “tag” is so small it is not really visible to the naked eye. As well, you need to fluoresce the particles in order to detect the pattern. This is apparently done with a confocal fluorescence laser scanning microscope, something you don’t commonly find laying around your workplace.

This makes it difficult in general to read out the markers, but it is possible. This creates a situation where a 3D printed part can be verified as a particular print, perhaps with its production information, its origins, its composition, its version, etc. You’d need to create a “reader” device that would flash the object to obtain this information.

In practice however, this is a bit futuristic, as the Nanoscribe equipment used by the researchers to create the structure offers only a tiny print volume. Thus it might be possible to use this approach only on small Nanoscribe-printed objects and not the more numerous larger 3D printers from other manufacturers.

I’m wondering if there is a way to incorporate this technology into other 3D printers so that they could insert an invisible 3D printed marker into the prints to serve this security purpose, which might become a lot more important in the future.

Via Nanoscribe