Technology has always been an inseparable part of the healthcare sector.

The technological advancements in the healthcare domain have been simplifying the diagnosis, the treatment, and the management of diseases, saving countless lives and improving the patients’ quality of life.

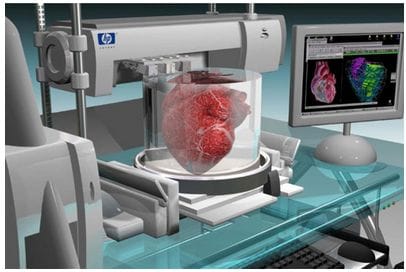

3D printing is demonstrating its potential in the medical and healthcare domain, revolutionizing the disease research and management and production of medical equipment. Consequently, the global medical 3D printing market is estimated to cross a value of USD 1.2 billion by 2024 with materials accounting for the largest portion of this number.

Though the 3D printing technology is relatively new in the healthcare segment, its applications in this area are growing owing to the benefits offered to the patients and the healthcare professionals.

Here are six latest applications of 3D printing that are transforming the healthcare domain scene worldwide.

1. Medical Equipment

3D printing has revolutionized the medical equipment segment, offering inexpensive and personalized benefits to patients worldwide and optimizing the supply chain in this area.

Medical equipment is often expensive owing to the associated material and maintenance costs. According to SelectUSA, in the year 2015, the total expenditure on medical devices in the United States reached around USD 140 billion.

3D-printed medical equipment such as finger splints, computer-aided exoskeleton for paraplegics, and organ and tumor models can improve patients’ quality of life, aid in medical research, and significantly reduce the overall cost of healthcare.

For instance, researchers in the U.S. and China are developing 3D-printed tumor models to study the development, the growth, and the spread of cancerous cells in the human body, aiding in the discovery of potent anti-cancer drugs.

Researchers are also using scans of animal organs to create 3D-printed organ models with multiple sensors. Once approved for its safety, this technology will soon be used to address the global shortage of organs for kidney, liver, heart, and lung transplantation.

2. Personalized Plasters

The orthopedic casts available today help in supporting the patients’ broken bones, enabling them to heal and fuse back together. Although these traditional casts serve their basic purpose they are bulky, heavy, and often exposed to moisture, causing skin irritation, itchiness, and even infections.

The 3D-printing technology performs a 3D surface scan of the affected area using an open-air photogrammetric scanner. The model of the patients’ affected body part is then used to digitize each bone and cartilage in order to create personalized plasters that suit the patient’s needs. These 3D-printed orthopedic casts are porous, light-weight, and designed to support the patients’ broken bone, enabling faster recovery.

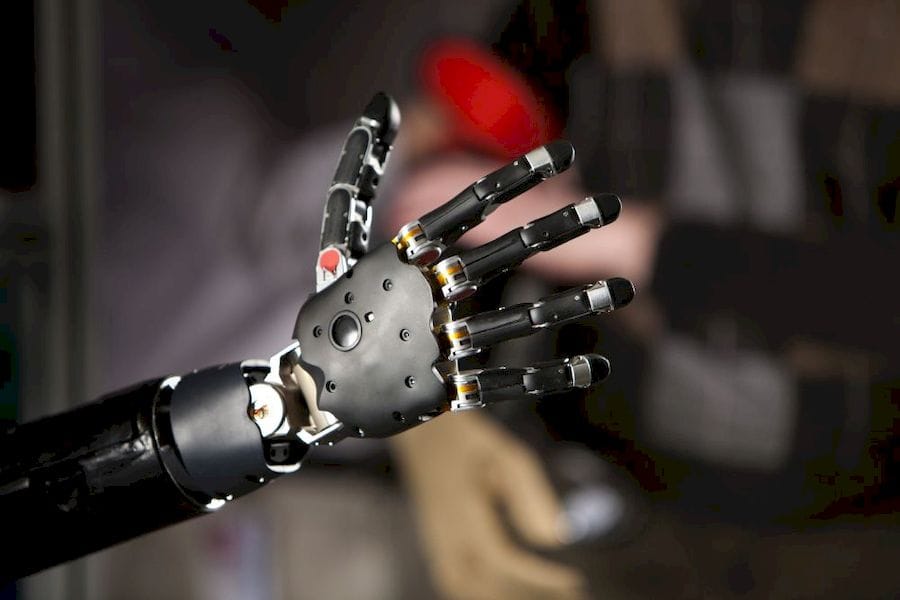

3. Prosthetic Body Parts

Globally more than 30 million people require prosthetic limbs and braces. Moreover, 80 percent of the amputees worldwide do not have access to the modern mobility devices. Consequently, prosthetic body parts are in huge demand.

The current prosthetics manufacturing process is quite complicated, time-consuming, and expensive. Depending on the patients’ needs, prosthetic body parts cost anywhere between USD$15,000 to USD$90,000 and require a production time of several months.

The recent innovations in prosthetic design and the ubiquity of the 3D printing technology are offering a viable solution for millions of patients worldwide who have lost their limbs. The 3D scanning and body modeling technologies enable manufacturers to design and create naturally-fitting prosthetic body parts that suit the patients’ requirements.

Researchers are working on applying advanced technologies such as propulsion systems, integrated sensors and micro linear actuators, artificial intelligence, robotics, predictive movement, and sophisticated algorithms in order to automate joint mobility. Furthermore, the 3D printing technology measures the tissue compliance of the limbs, designing prosthetic sockets that comfortably fit and offer a better interface with the human body.

4. Biomaterials

The 3D printing technology is promising to create complex biomedical devices such as implants and scaffolds for tissue engineering using patient-specific data. The application of 3D printing in the field of tissue engineering is slowly evolving owing to its ability to design and fabricate complex biomedical structures.

For instance, 3D biomedical devices can restore anatomical defects by reconstructing the complex 3D microarchitecture and nanoarchitecture and scaffolds for stem cell differentiation.

Depending on the application, the processing methods, the FDA approval, and the cell-material interactions, polymers (natural or synthetic), ceramics, and metals can be used as biomaterials in 3D printing of blood vessels, cartilages, heart valves, and skin.

5. 3D-Printed Medications

Spritam, an anti-epileptic medication that is manufactured using the 3D printing technology is the first drug to be approved by the US FDA. This approval has opened up a whole world of opportunities for the patients, the healthcare professionals, and the pharmaceutical companies worldwide.

The availability of 3D-printed medications will enable practitioners to dispense customized medications, evade the availability of counterfeit drugs, and take care of other regulatory issues such as mislabelling of medications. 3D printing technology assembles the drug at a molecular level, enabling doctors to prescribe a formulation that delivers the exact dose to their patients.

The technology will also enable pharmaceutical firms to have better control over the drug composition in comparison to the conventional tablet press technology.

In the near future, healthcare practitioners and pharmacists will also be able to offer customized formulations to the patients based on their special needs. Thus, when a doctor sends an e-prescription to the pharmacy that uses a 3D printer the pharmacist will create and dispense the prescribed 3D-printed medications to the patient.

6. Custom Sensors

The 3D printing applications will soon find a place in the manufacturing of electronic actuators and sensors used when making smarter prosthetics and medical equipment. The sensors are manufactured in various layers, namely the silicone interface layer, the bottom electrode layer, the coil-shaped sensor, the isolating layer, the supporting layer, and the outermost electrode layer. Researchers are working on overcoming a few challenges in this field such as printing the sensing elements, the conductors, and the insulators.

These silicone sensor devices can be attached to the human body, enabling early detection of illnesses based on various health parameters. For instance, in patients with cardiovascular disorders, these sensors can help in detecting the number of blocked arteries and heart strain.

The 3D printing technology is slowly and steadily making inroads in the healthcare domain. This ground-breaking technology is expected to revolutionize the medical field by offering accurate, faster, and economical ways to deliver personalized health care to patients worldwide.

The above-mentioned points will help you appreciate the growing significance of 3D printing in the healthcare domain.

According to a report shared at the World Economic Forum, five major technologies will revolutionize the healthcare domain in the years to come, namely the Internet of Things, artificial intelligence, advanced robotics, smart wearables, and 3D printing. Amongst these technological advancements, the 3D printing technology has infinite possibilities for 3D bioprinting of organs, tissues, medications, and medical devices.

Consequently, this ground-breaking technology is expected to transform the medical field by offering accurate, speedy, and economical ways to deliver personalized health care to patients worldwide.

The above-mentioned points will help you appreciate the growing significance of 3D printing in the healthcare domain.