Industries all start in a chaotic mode, but after a time standards must emerge.

When conceived, few have any idea where an industry might go, and what constraints or recommendations might be required in the future. But that’s part of development: experimentation must take place in order to discover the techniques that work, and those that don’t. It’s survival of the fittest.

And that is certainly the case in the 3D printing industry. While it began quietly in the mid 1980’s, it was only in the past decade that a veritable explosion of technologies emerged. More recently we’ve seen dramatically increased adoption by industry as a valued method of producing objects, either for development or actual end-use production parts.

As an industry moves deeper into production in particular, there is a need for standards. These would be approaches for measurement, categorization and certification. While a hobbyist may have little interest in such things, they are of great value to a company producing end-use parts, because those parts must meet requirements, some of which can be derived from official standards.

But are there any official standards for 3D printing? Who would make them?

It turns out there is an organization that is dedicated to do exactly that. ASTM International is a century-old organization that develops and publishes voluntary standards for many industries. Currently they boast of over 12,000 official standards that are used worldwide.

Recently they’ve been getting into 3D printing, as it has reached the stage where the existence such standards make sense for larger companies involved with the technology.

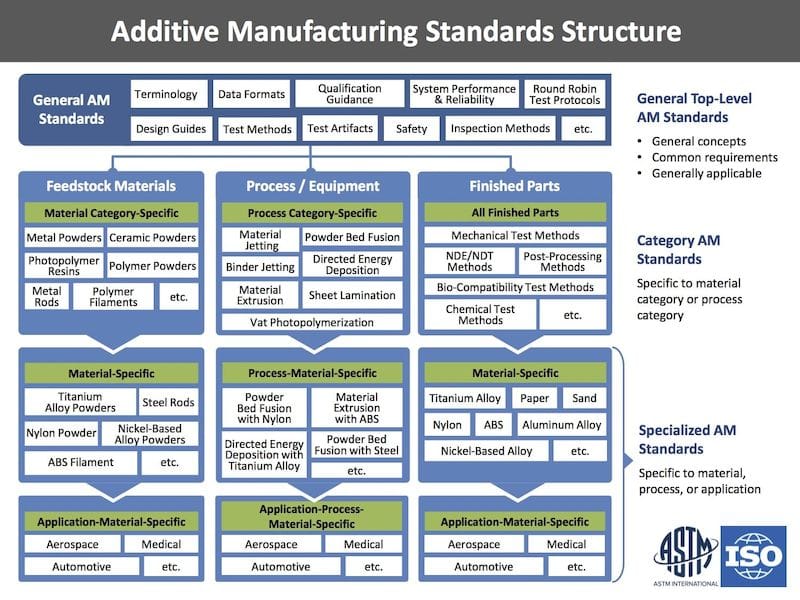

In late 2016 ASTM International, in cooperation with ISO, announced a framework for global 3D printing standards, called the “Additive Manufacturing Standards Structure”.

A framework isn’t exactly a set of standards, but it is a key step on the way to producing standards. It’s essentially a very high level set of categories that represent the entire spectrum of the 3D printing industry. Let’s take a tour of their concept.

They’ve divided the entire 3D printing industry into three high level divisions: Feedstock Materials, Process/Equipment and Finished Parts. While the first two might be obvious, the last one relates to quality control, testing and measurement of parts once they are produced. It’s like the “before”, “during” and “after”, if you look at it from the lifecycle of the material.

Within each division they’ve further separated each into levels relating to material specificity, process specificity, and application specificity. What’s of most interest to me is the first level, which is the basics of each division. For materials, they list the obvious powders, resins and filaments, but in the Process / Equipment division the AMSS lists seven specific 3D printing processes they believe encompass the entire industry:

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Directed Energy Deposition

- Sheet Lamination

- Vat Polymerization

Most of these should be familiar to readers, and as I type them I am mentally assigning different vendors’ equipment to each. This tells me they are correct.

But again this is merely a framework, and one can see they will eventually begin to fill in standards within each box. It’s not the standards themselves, but it is a way to start making them. It’s the clothesline that you can pin them to. ASTM says:

The new structure will help:

-

guide the work of global experts and standards development organizations involved in AM standardization;

-

identify standards-related gaps and needs in the AM industry;

-

prevent overlap and duplicative efforts in AM standards development;

-

ensure cohesion among AM standards;

-

prioritize AM standards areas; and,

-

improve usability and acceptance among the AM community, including manufacturers, entrepreneurs, consumers, and others.

All good, and I’m interested to see what develops, which will clearly take many years.

Meanwhile, the mere existence of this work demonstrates that the 3D printing industry is swiftly maturing.

Via ASTM