This is quite interesting: a new approach to enable 3D metal printing of metal alloys that were previously extremely difficult to use.

HRL Laboratories, an organization jointly owned by General Motors and Boeing, announced the results of their research, which attempts to overcome the problem of “hot cracking”.

This issue occurs when high-strength, unweldable alloys are 3D printed using powder-bed laser 3D printing techniques. The layers are not properly adhered and resulting parts can easily fall apart. This means a number of highly desirable strong alloys cannot currently be used in 3D metal printing systems.

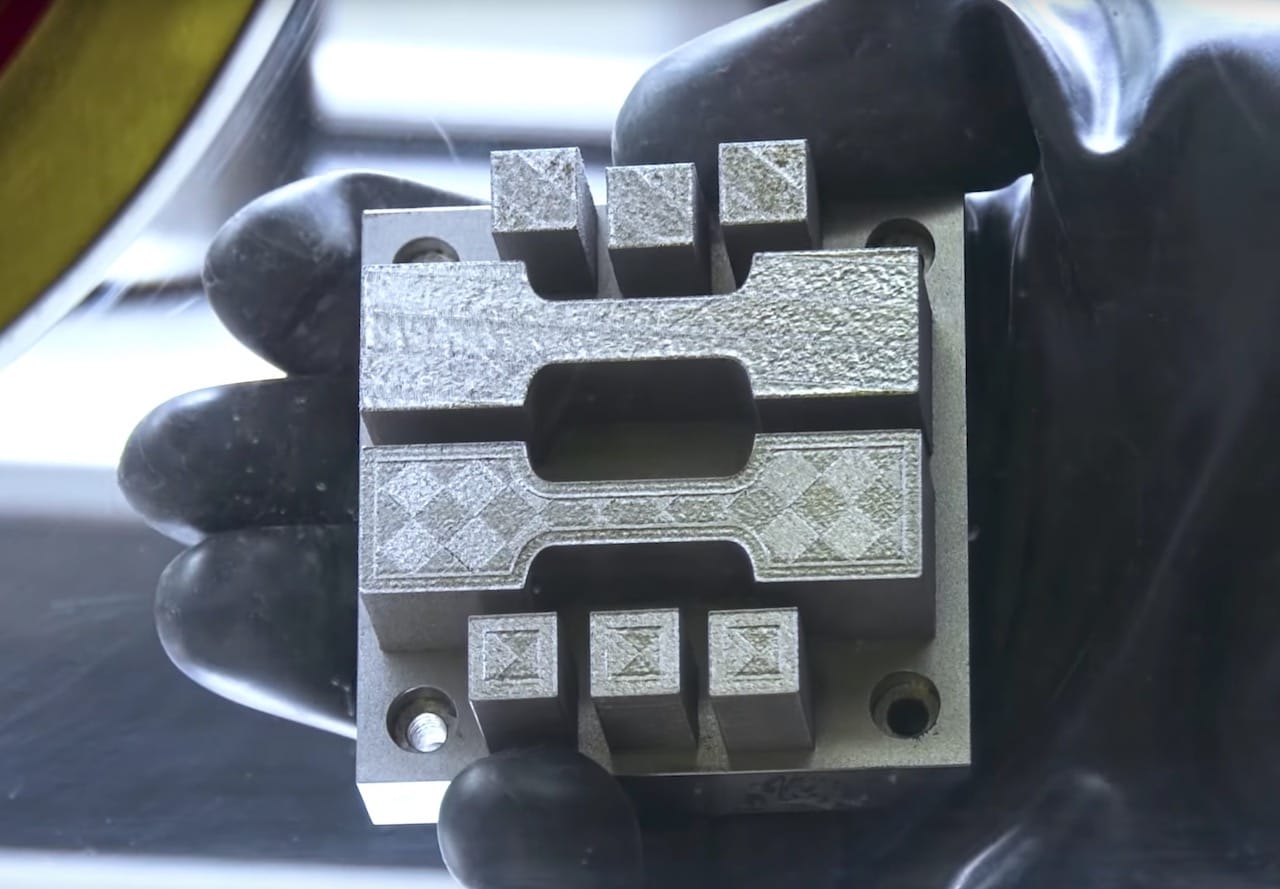

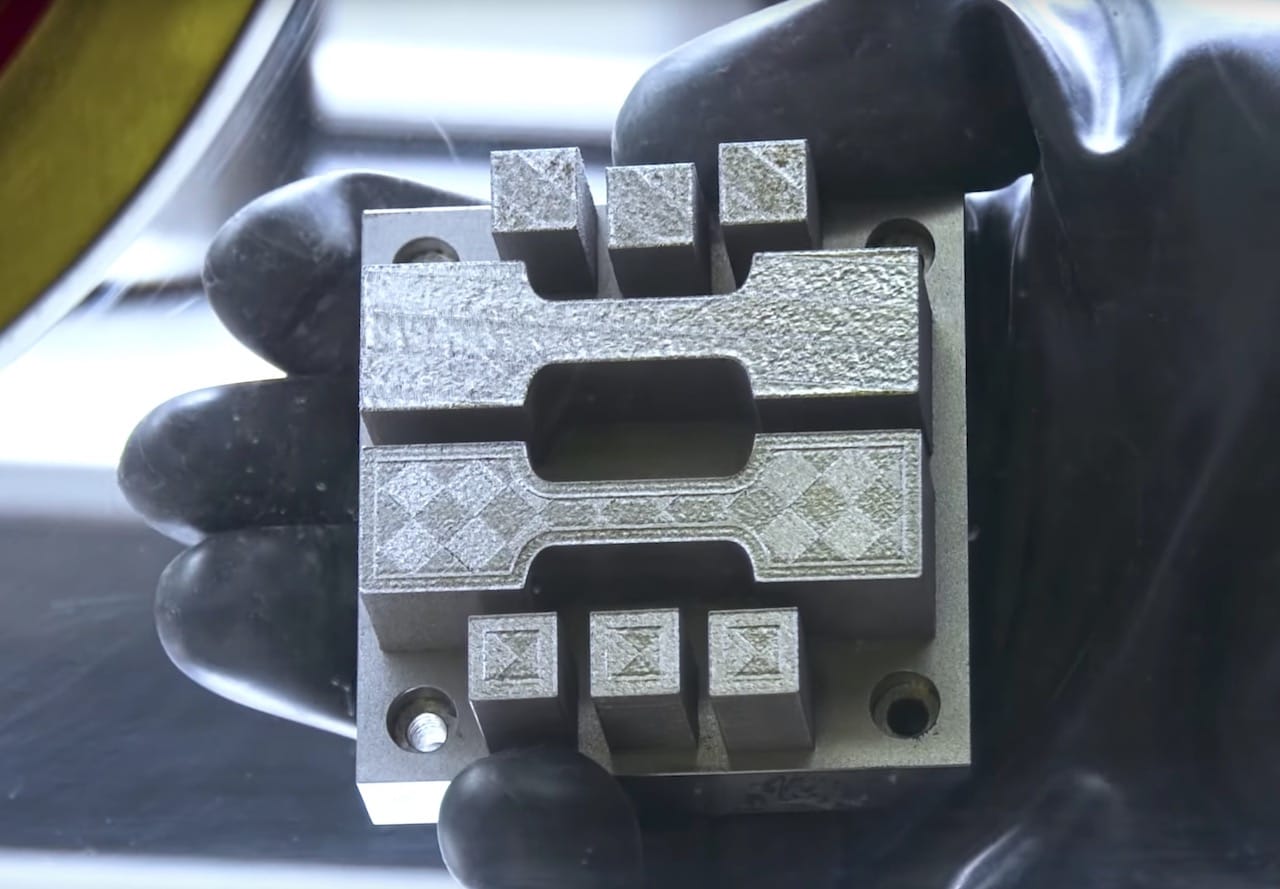

However, the HRL Laboratories folks identified a new approach: they coated the alloy powder with specific nanoparticles that can act as nucleation sites, in a process known as lattice match nucleation. The resulting crystallization provides far more strength. In other words, the layers are properly fused and the resulting parts actually retain the strength characteristics of the raw alloy.

Apparently the nanoparticle application process is said to be “scalable”, which I take to mean “financially feasible”. HRL Laboratories says it uses “low cost materials”. It’s not clear how these nanoparticles are applied, whether it is after the powder is created or during the process in some way.

HRL Laboratories also suggests that while the research involved two specific aluminum alloys AI7075 and AI6061, the process likely works on many other unweldable alloys, opening up the possibility to 3D print a vastly greater range of metal materials.

For users, this could be a huge deal, as it could enable far more types of critical parts to be 3D metal printed, whereas today there are constraints on the material types. There may be parts that cannot be used unless they are in specific materials, and that’s what’s being addressed here.

For metal powder manufacturers, this could be good or bad news. If the process is used by competitors, they may be able to sell different, desirable types of materials to customers. To be used in house, however, the powder manufacturer would likely have to obtain a license for the technology at undetermined cost.

One of the biggest barriers facing 3D print technology from gaining in the manufacturing marketplace has been the very limited set of materials available. Now, that might change. Expect to see new materials emerge, followed by a wave of new 3D metal printing applications.

Via HRL Laboratories