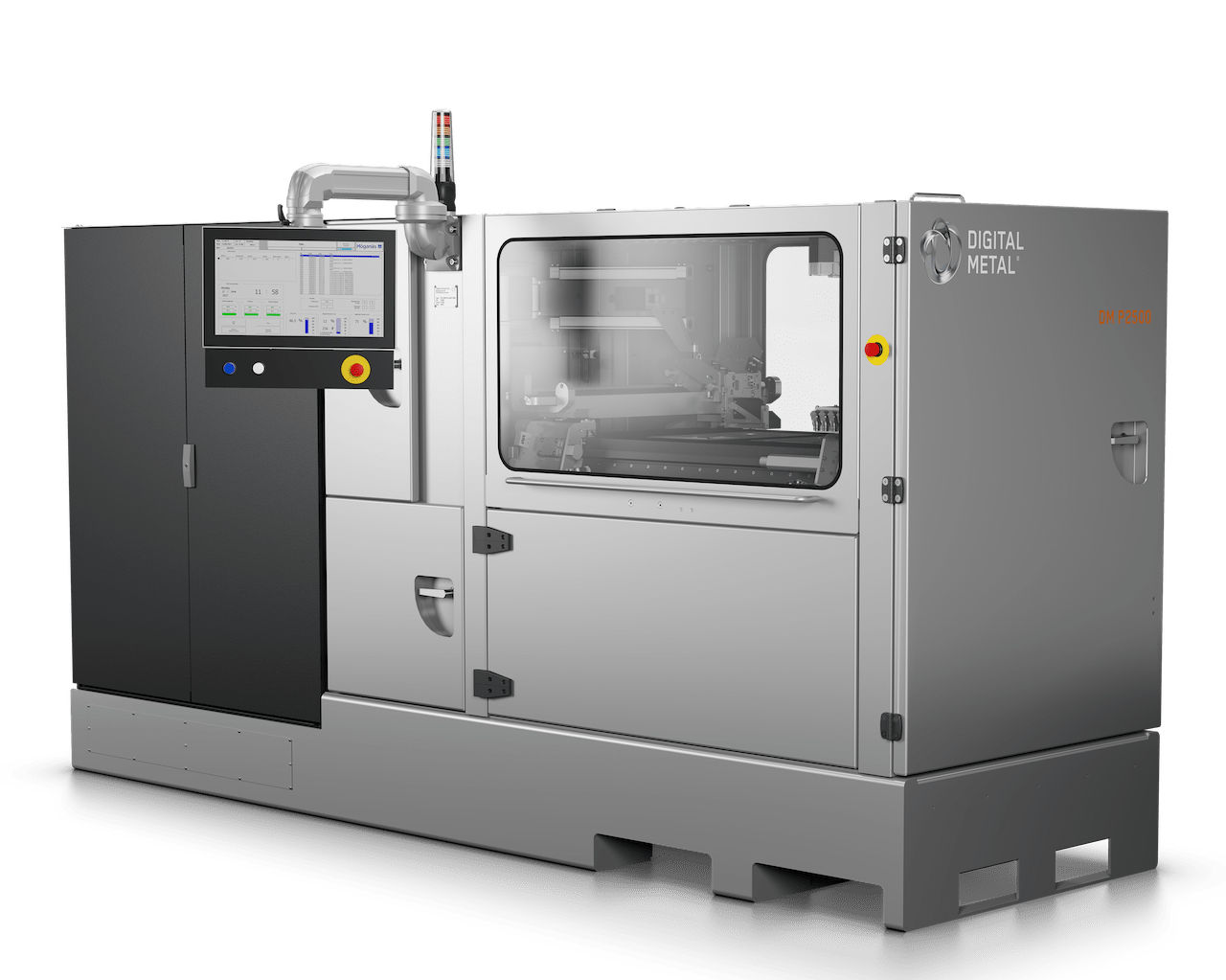

Digital Metal, part of Sweden-based Höganäs AB, has now launched their incredible 3D metal printer, the DM P2500.

Digital Metal’s process is quite different from mainstream 3D metal printers in that it does not use a hot process to form the 3D objects. Other systems use powerful lasers, electron beams or heat sources to fuse fine metal powder, but not the DM P2500.

It uses a binder jetting process. Here’s how it works:

- A very fine layer of metal powder is distributed evenly over the print bed.

- An inkjet-style print head moves over the powder bed and selectively deposits liquid binder.

- Another layer of metal powder is applied and the process repeats.

- When the object is printed, the non-bound metal powder is blasted away by air jet, revealing the printed objects.

- These “green parts” are then carefully placed in a sintering furnace.

- The heat from the furnace burns away the binder and fuses the metal particles together, completing the part.

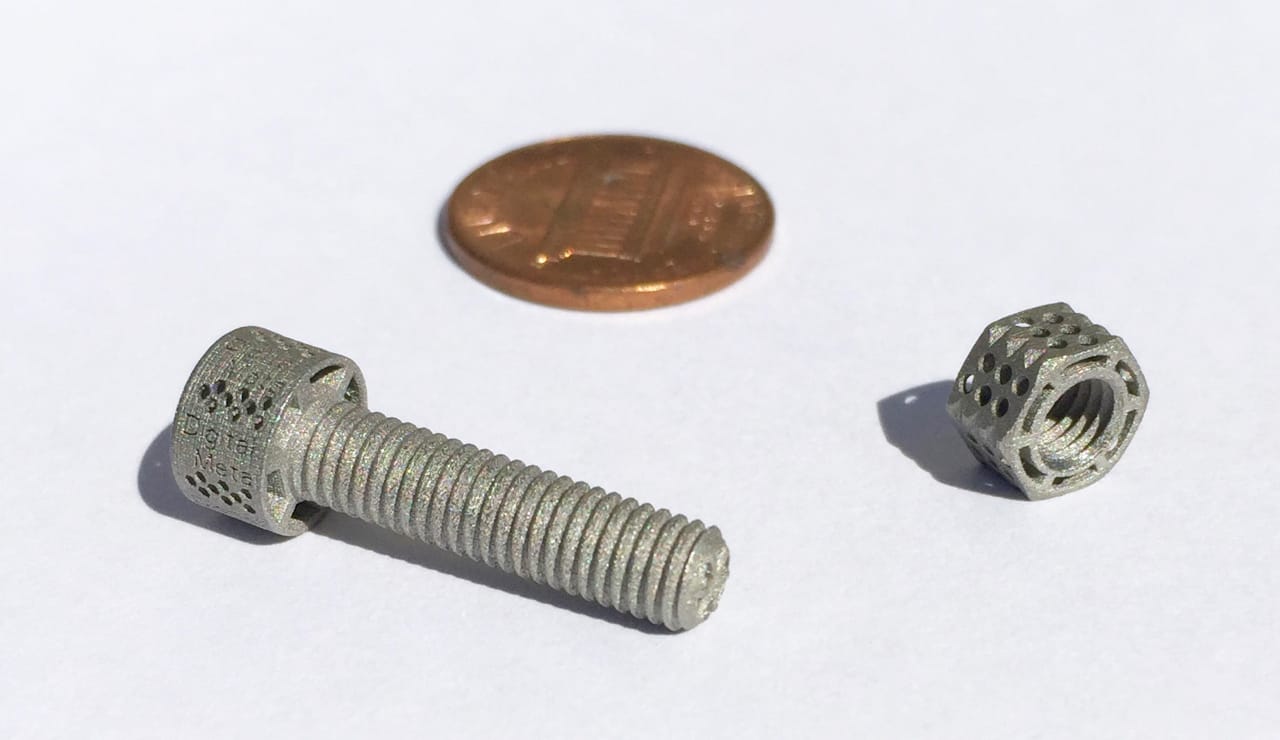

The results of this process are astounding, as you can see in the image at top. I’ve seen several examples of what the Digital Metal process can achieve and it’s perhaps the most detailed metal prints I’ve yet encountered.

And as this is a powder-based process, there is no need for support structures and associated thermal analysis as is required for machines using other making processes.

The change now is that the company has officially launched this machine for commercial sales. They say:

Digital Metal®,a Höganäs Group company, the world’s leading producer of metal powders, today announced it has initiated commercial production of the industry’s first high precision binder jetting 3D metal printer that can produce smaller and more intricate components than any previous technology. The DM P2500 can be purchased or licensed from Digital Metal and is ideal for serial production and customised parts, opening up the possibility to print what was once impossible.

The relevant specs on the DM P2500 are as follows:

- Layer size (Z) of 0.042mm

- XY resolution of 0.035mm

- 2,500cc build volume (not sure of the dimensions, but likely around 135mm on each side)

- Uses stainless steel powder (with titanium, silver and copper coming)

We are not certain of the pricing of the system, but it is likely to be in the mid-six figure range, based on the estimated pricing of their previous model, the DM P1000, which at one time was priced around €600,000 (USD$664,000). However, this production-level machine is able to rapidly produce high volumes of small customized metal objects.

The DM P2500 appears to be a slightly larger version of their previous models, the DM P1000 and DM P2000. Now the DM P2500 likely hits the sweet spot for manufacturers seeking fine metal printing capability. Digital Metal has installed some early machines at customer sites where they no doubt received feedback on the system’s characteristics.

This machine isn’t for those requiring larger metal parts, but is targeted specifically at those manufacturers requiring low volume production of very finely detailed small metal objects. It’s quite different from the typical 3D metal printers on the market, but addresses a specific niche.

Via Höganäs