MakerBot has undergone an incredible transformation in its brief, 8 year existence. Now it’s apparently a “shop machine”.

In a recent video published by MakerBot, they explain how the Replicator+ is being used at Local Motors. That company has been developing an automated robot bus concept called, “Olli”, and apparently have been extensively using 3D print technology through the development process.

Local Motors has significant experience with 3D printing technologies, having developed one of their own specifically for use in creating one of the world’s first 3D printed automobiles, the company now leverages the same technologies on their latest project, Olli.

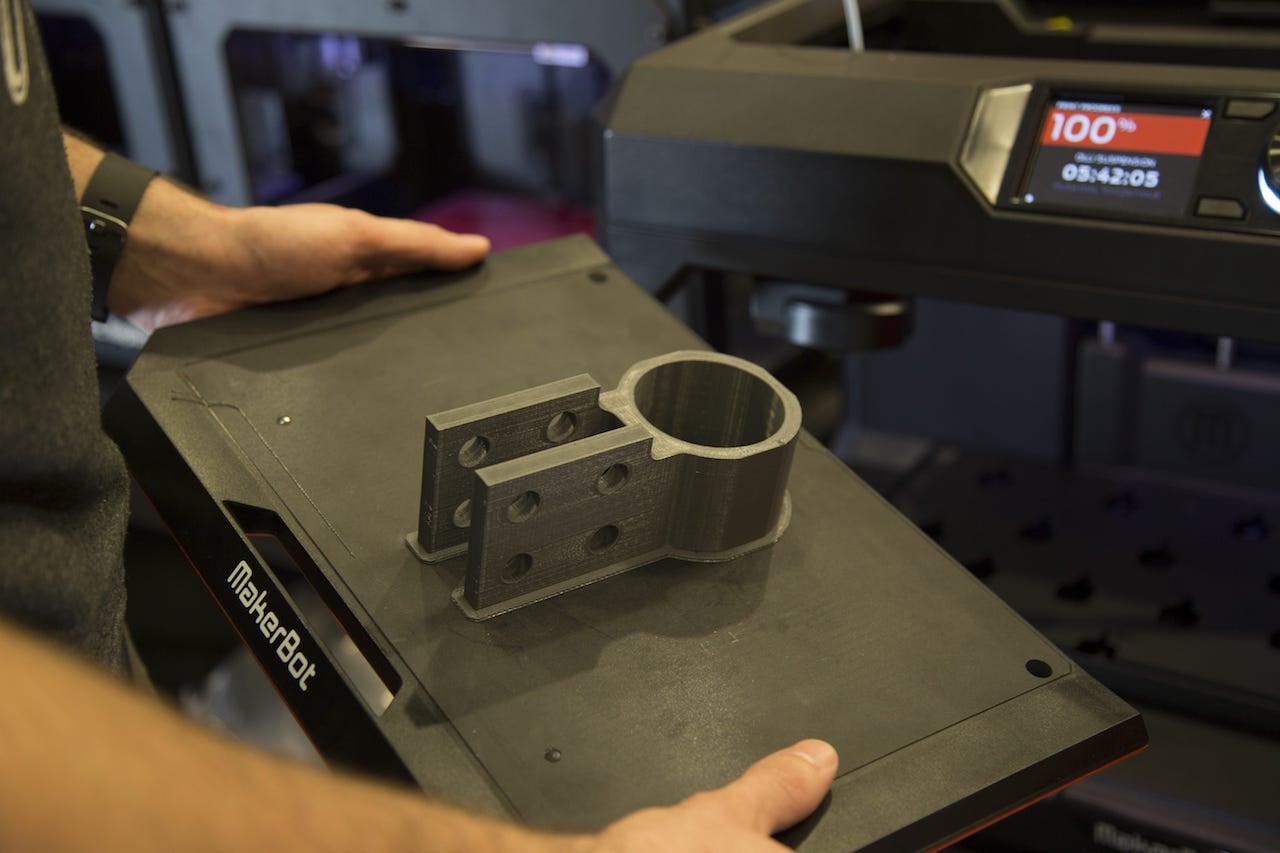

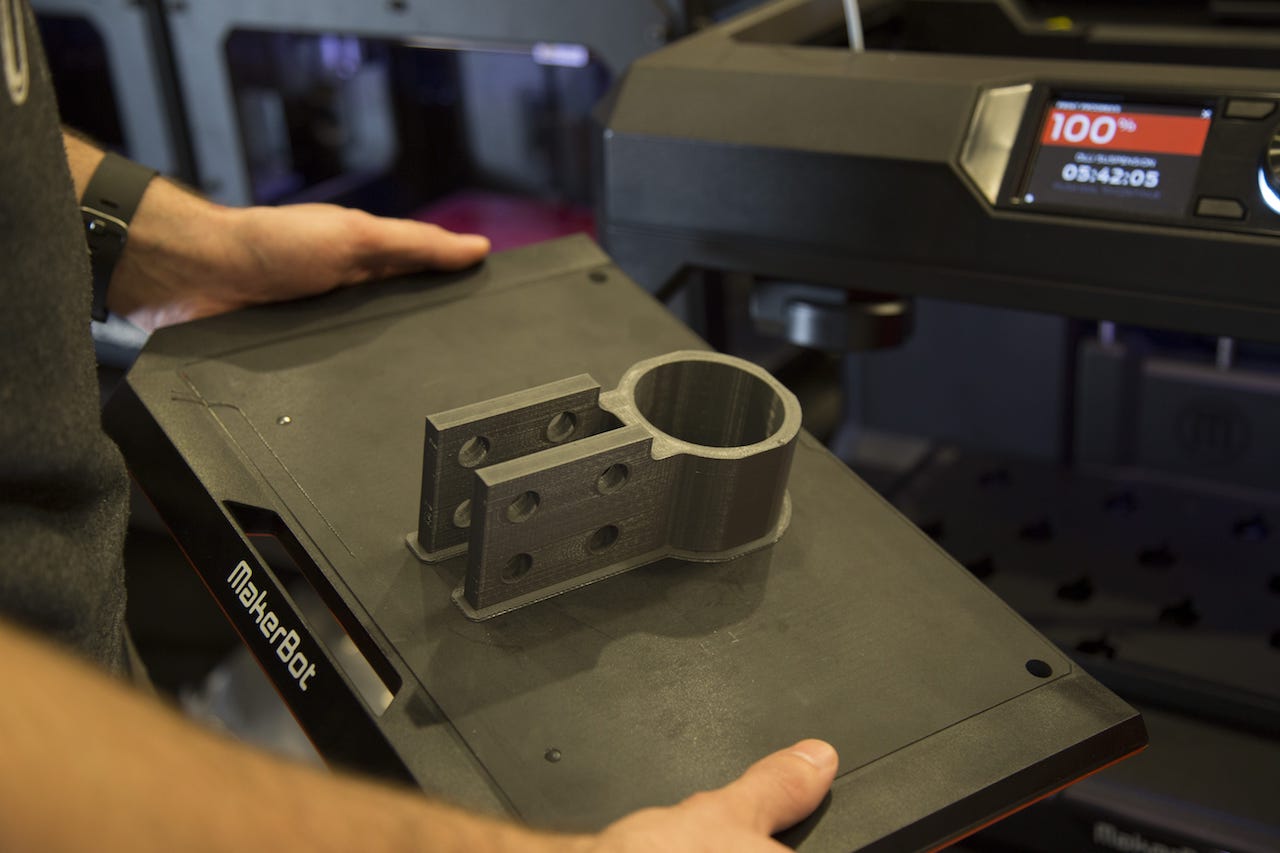

In the video, Local Motors representatives describe their use of 3D printing, which includes the rapid creation of production tooling jigs, prototyping mechanical parts and the creation of molds for vacuum forming pieces of Olli.

That’s all very good and proper uses of 3D printing, although I expect that the larger vacuum forming molds are produced on Local Motors’ large-format 3D printers, not on the MakerBot Replicator.

That said, a Local Motors’ Director of Product Development, Alex Fiechter described the Replicator as a “shop machine” in the video. What might that mean? He says:

We’ve been using the new Replicator+ recently and so far it’s been a great “set and forget” experience. It really operates like a “shop machine”.

To me, a “workshop machine” is one that, with appropriate regular maintenance and proper operation provides reliable and consistent output.

Does the MakerBot Replicator+ have those attributes? Some may debate this proposition, as MakerBot considers its Smart Extruder+ as a consumable unit; they wear out and you must replace them periodically.

This is a bit of a different concept from a machine that “runs forever”, without the need for replacement parts. Some may consider other machines that “last longer without maintenance” more of a “shop machine”, but it depends on where you’re coming from.

A MakerBot Replicator+, if properly maintained (including replacing the extruder at appropriate moments), should last a very long time and continue to produce consistent output. It may cost you a bit more to maintain than a machine that requires less frequent attention, but that may not be an issue for a company that is attracted to MakerBot’s integrated and easy to use software system.

Companies make machine buying choices based on a number of factors beyond just the hardware specifics, and it appears that MakerBot is addressing those aspects successfully, at least as far as Local Motors is concerned.

Via MakerBot