3D printer manufacturer Markforged has introduced a couple of new machines that alters their product lineup considerably.

Markforged has made a name for themselves with their ability to 3D print strong carbon fiber parts. Introduced at a time when typical 3D printers were able only to 3D print in PLA and ABS, the Markforged device was a revelation.

Since then they’ve refined their product line to better match the needs of clients, particularly with today’s announcement. They’ve added two new models, the X3 and X5, and renamed another to become the X7.

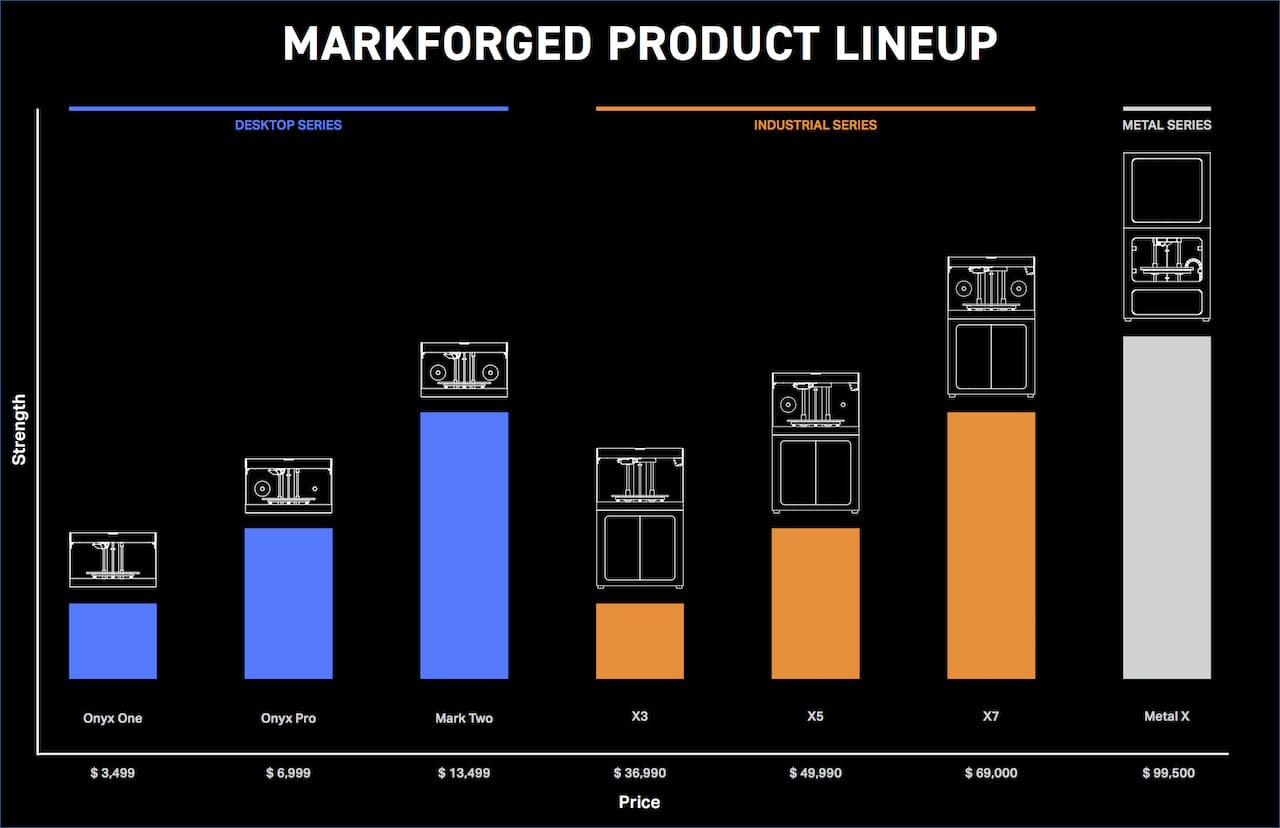

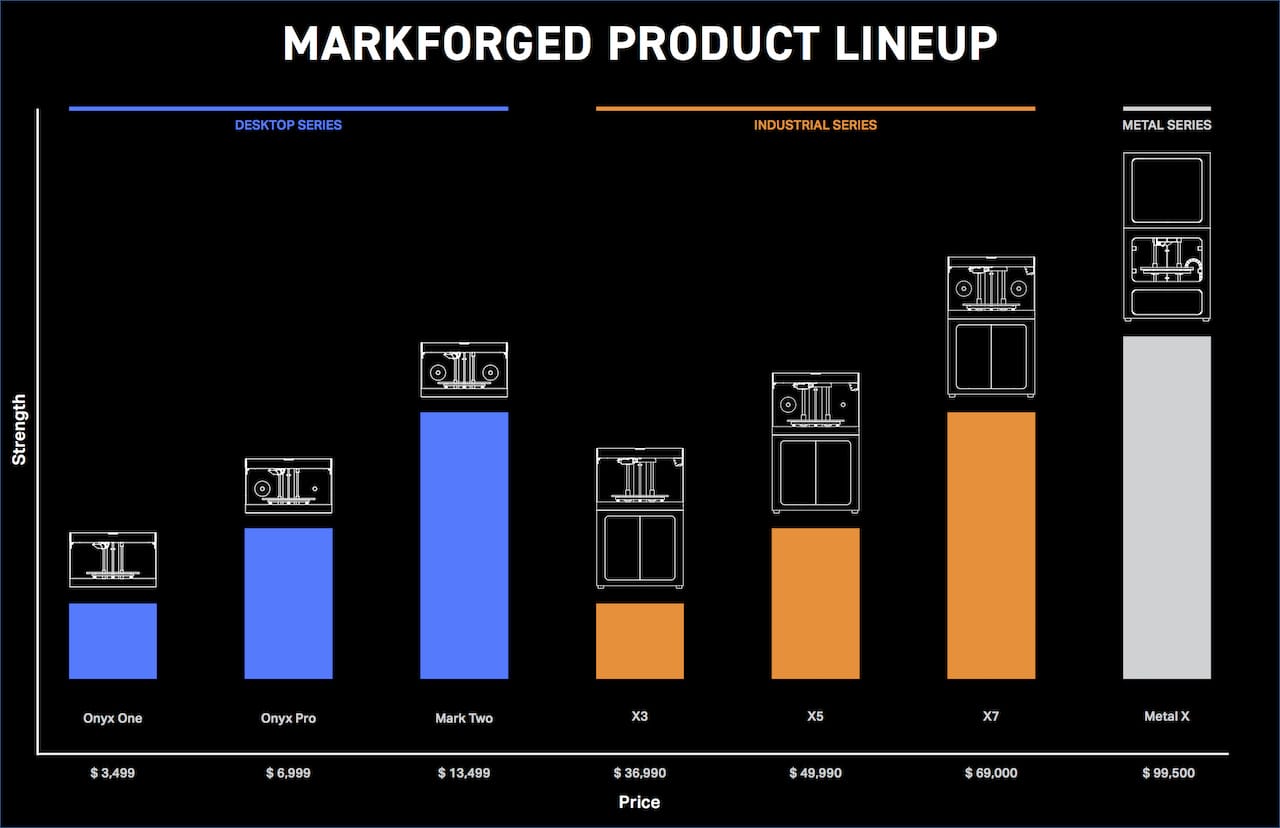

At top you can see their current product lineup, which now includes six different machines at significantly different price levels. I think this is the key to their strategy: pricing.

On the right hand side, the Metal X is a specialized device that prints green metal parts that, after high temperature exposure in a furnace, become usable metal parts. That machine is quite different from the remaining products, which print only thermoplastics.

Markforged’s claim to fame is the ability to make extremely strong parts. They do this through ingenious use of materials. Nylon is normally the “weakest” material they print, but it is considered a very strong material by typical 3D print operators. They make those nylon parts stronger by embedding either continuous strands of fiberglass or carbon fiber.

And this leads to their product strategy. The new machines, the X3 and X5 fit in like this:

X3: prints only their nylon material, Onyx. It is carbon fiber reinforced, however, with fine carbon fiber particles mixed in.

X5: Prints Onyx and adds continuous fiberglass capability.

X7: (which previously was their model “X”) prints Onyx and fiberglass and adds continuous carbon fiber capability.

See how this works? Add a capability and get a more powerful 3D printer model. Of course, the pricing of these three matches their capabilities, at USD$37K, USD$50K and USD$69K respectively.

Why has Markforged broken these machines down in this way? I think they are feeling pressure from other vendors who have increasingly marketed inexpensive machines capable of 3D printing nylon, and even carbon reinforced nylon similar to Onyx. That market is no longer as empty as it was when Markforged emerged.

For customers, they faced the choice of buying the relatively expensive Model X or spending far less on a competing model that printed strong nylon. I suspect Markforged saw a bit being taken from their market, thus the introduction of lesser expensive models to compete with the others.

Will the strategy succeed? Perhaps, although the competition is typically still less expensive, although not quite as capable as Markforged’s machines.

Via BusinessWire