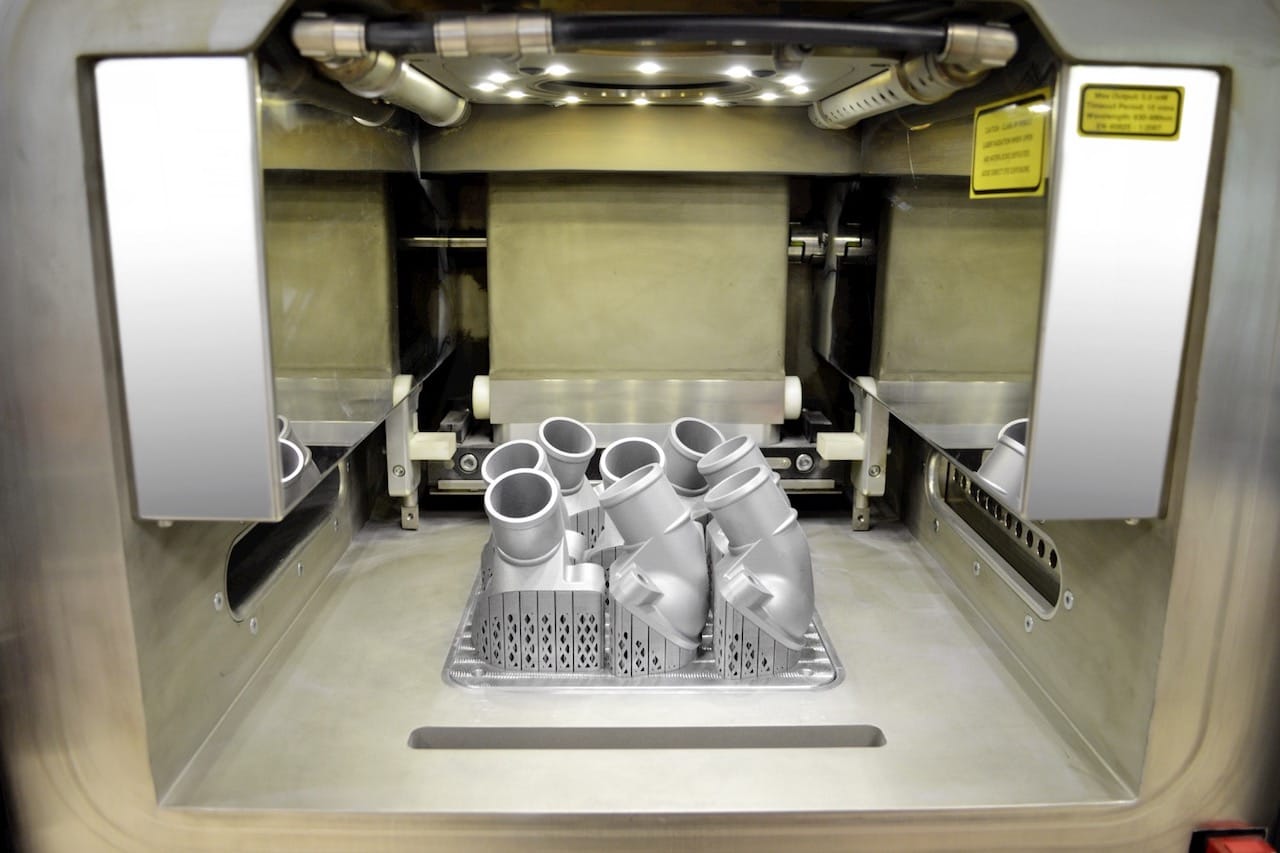

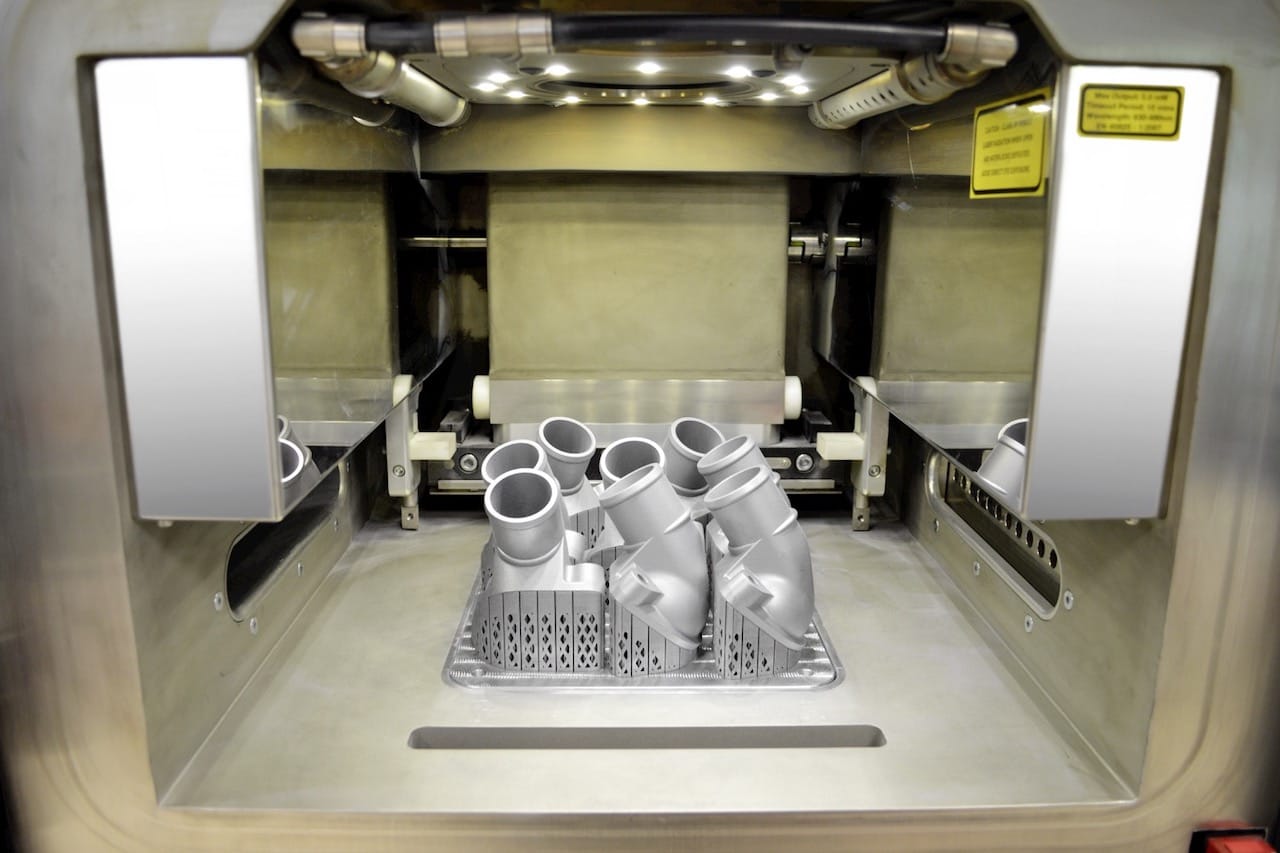

A report suggests that Daimler is now 3D printing replacement metal parts for some of their obsolete models.

Apparently the parts are for certain older models of Mercedes-Benz trucks that are no longer in production. Previously the company had experimented with certain plastic parts, but now has moved into metal parts as well, and those are usually a lot more important for vehicles.

The service has a number of benefits and implications.

For those owners of older vehicles in the program, it means they may not have to prowl junkyards and classified ads to procure critical missing parts, as they might be available directly from the manufacturer for the indefinite future.

For Daimler, it means they do not have to maintain a potentially costly large supply of very infrequently requested spare parts, nor do they have to maintain a production line capable of making batches of said parts.

Instead, Daimler merely needs to maintain a digital inventory of the parts and have a means to produce them on 3D printers when required. Of course, those 3D printers could be shared and used for many other purposes, unlike a dedicated production line.

It’s far more efficient for all concerned.

And there’s another implication here, one that might portend a pattern in industry.

It goes something like this: one key premise of the consumer 3D printing craze of 2012-2015 was the idea of consumers 3D printing their own spare parts for various devices and machines. However, this never came to pass for a couple of reasons: the equipment was likely not up to the task of producing a quality part, and secondly the digital models of the spare parts were retained privately by the originating company.

Even if the consumer had access to appropriate machinery, the design was unavailable.

But it seems that the idea has switched around a bit: instead of the consumer 3D printing the spare part, the company does so instead, because they have the equipment, and more importantly, they have the digital design files.

The same process occurs, it just happens at a different place.

Could this business model emerge in other industries? I hope it does, as it would greatly assist everyone by providing access to previously unavailable parts.

However, there are reasons it might not be so. One key barrier is that a company may decide to NOT make older spare parts available to encourage owners to buy entirely new products and abandon their old units. Another is that the originating company might be out of business entirely and there is no one with the digital design files.

The precedent set by Daimler is good; I hope other ongoing businesses take up the same process.

Via Digital Trends