A study published in Technologies examines the effect of 3D printed toys, specially at MyMiniFactory.

MyMiniFactory is certainly one of the best 3D model repositories to obtain 3D models for toys, as the company literally test prints each and every submission, tuning them before releasing. This ensures a higher probability of print success by their users.

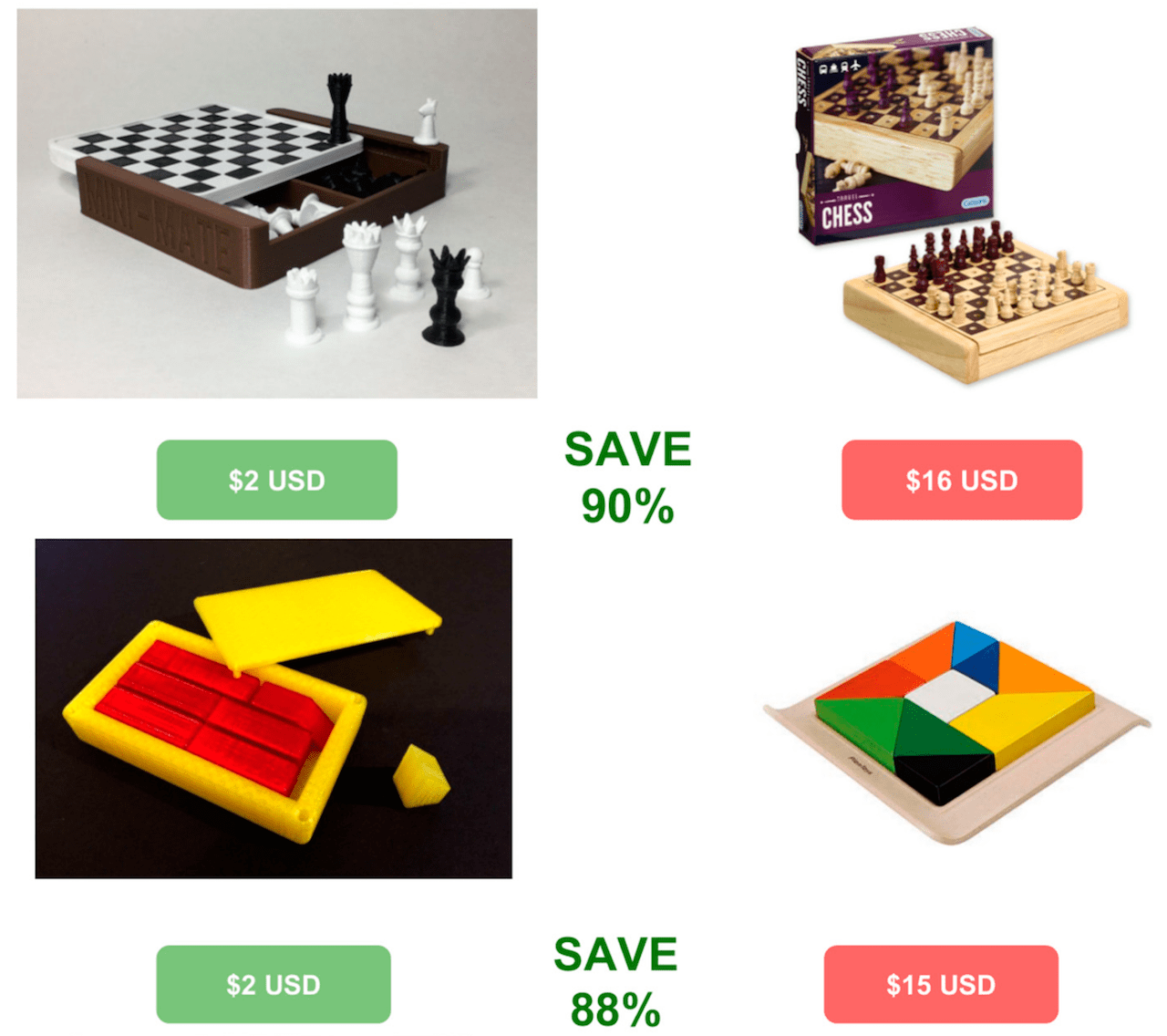

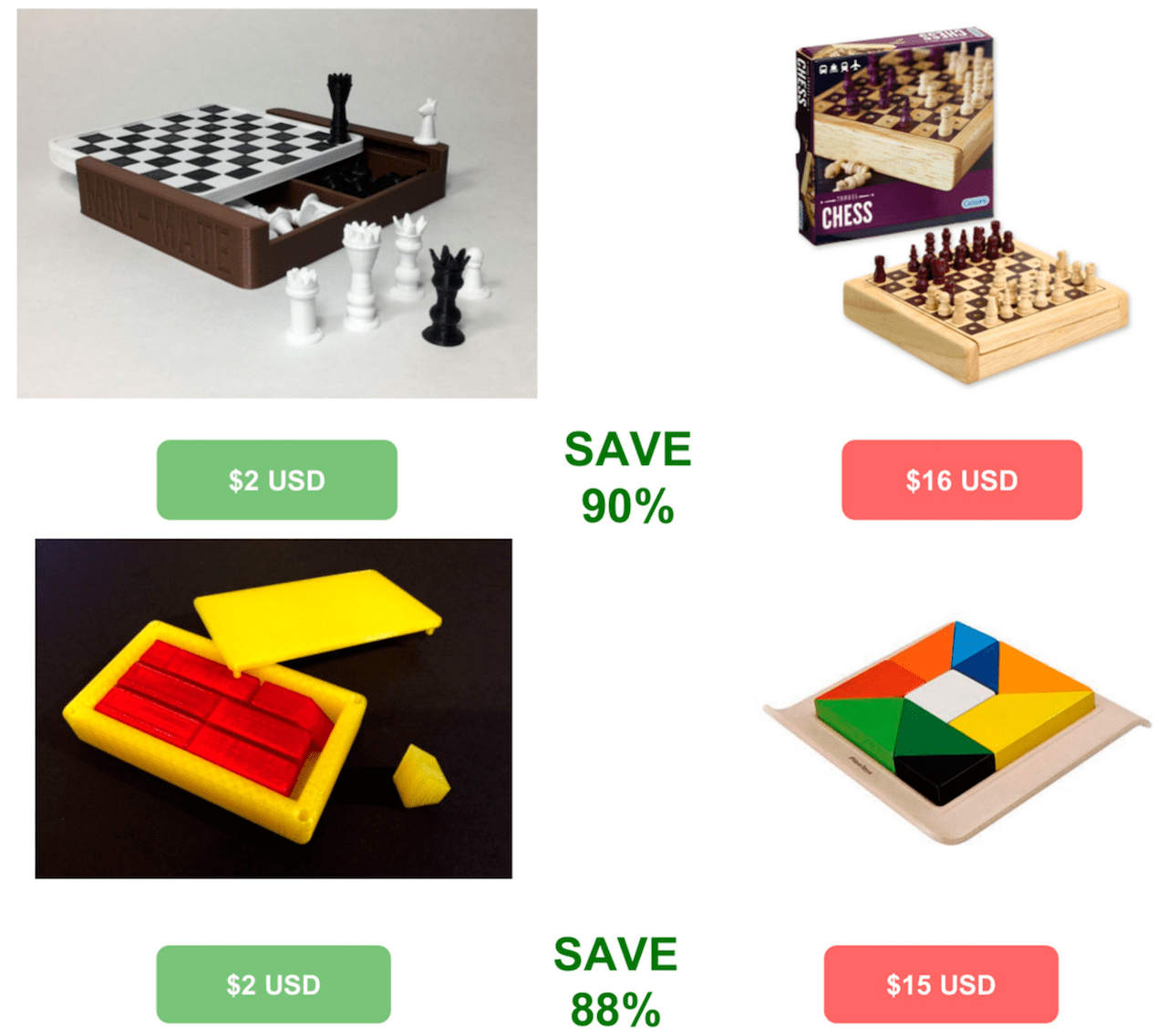

The study examined the notion of cost when 3D printing toy 3D models using a service like MyMiniFactory. Essentially, they compared the material cost of 3D printing specific 3D models opposite the cost of obtaining the same or similar toys from commercial sources.

They found, not surprisingly, that the cost of 3D printing the toys was smaller than buying the toys from traditional sources, particularly when recycled filament or filament made from pellets was used instead of retail 3D printer filament. This again is not surprising.

While I generally agree with their conclusions, there are some complicating factors that make the picture not quite as clear.

Certainly it is possible to make one’s own 3D printer filament using recycling techniques or from raw pellets, this is so infrequently done it should not be a major factor. Currently the quality of such homemade filament is typically so poor that it is often unprintable, or significantly increasing print failures that would require re-printing and thus use more filament.

The researchers don’t seem to have accounted for the cost of the 3D printer itself, while they have accounted for the materials printed. While some desktop 3D printers are now available at ridiculously low prices, sometimes approaching USD$100, these machines are not necessarily that inexpensive.

A reasonable 3D printer cost might be USD$500 or above, particularly for easy-to-use machines that the general public might be more amenable to using. Currently I suspect the public might work best with machines costing over USD$1,000. For a machine used only for say, three years, printing ten items per month, this could add almost USD$3 per print.

They may require assembly, and they may require significant maintenance to make them work properly. Typically the more expensive machines that produce reliable prints have additional sensors, software and upgraded components that encourage print reliability. There is something to be said for the amount of personal time required to acquire, setup, operate, maintain, upgrade and fix a personal 3D printer. Those time costs are almost zero for a purchased product, but are very present if printing one’s own items.

Another issue in this scenario is that often toys, particularly in the mass market, are not actually available for 3D printing because their owners wish to keep the profits for their own manufacturing operations.

An example might be a 3D model from a character in a popular summer movie. This would almost certainly not be released to the public as a free 3D model, and would only be available through the normal – and expensive – channels.

Certainly there are a limited number of such items on public repositories, such as lego blocks (which were analyzed in this study specifically), but most of the time the designs are held close. Some 3D model repositories do offer commercial 3D models, but they are often priced at a non-zero value, adding to the cost of 3D printing them.

Sometimes commercial 3D model characters are available at no charge, but they are often used without the owner’s permission, creating a licensing risk for the publisher and duplicator.

The picture of personal toy 3D printing is a bit fuzzier than the paper proposes, but nevertheless there will be a niche set of users that:

- Have a reliable 3D printer

- Don’t care about the time required to run it

- Are OK printing available 3D models and don’t miss the unavailable ones

For them, sites like MyMiniFactory are gold.

Via Technologies