Some say 3D printed parts are not strong, but they can be made much stronger than you suspect.

I recently read a publication stating that 3D printed parts were weak and used only for prototypes and “toys”. While those applications are certainly true, there are many people now using 3D printed parts in production scenarios, mainly due to various techniques for strengthening parts.

But how, exactly, do you strengthen 3D printed parts? It turns out there are multiple ways to do so, with varying levels of effectiveness. You may have tried some of these, but perhaps not all.

Interior Density: The most obvious method of increasing part strength is to simply increase the interior density of the print. Most 3D print slicing systems offer the ability to select a percentage for the interior density, with 0% being entirely hollow and 100% being completely solid. Most often I select a level that matches the degree of strength required, compromising with the use of material. It’s pretty rare that you need something 100% solid, but it’s possible and makes for a much stronger part.

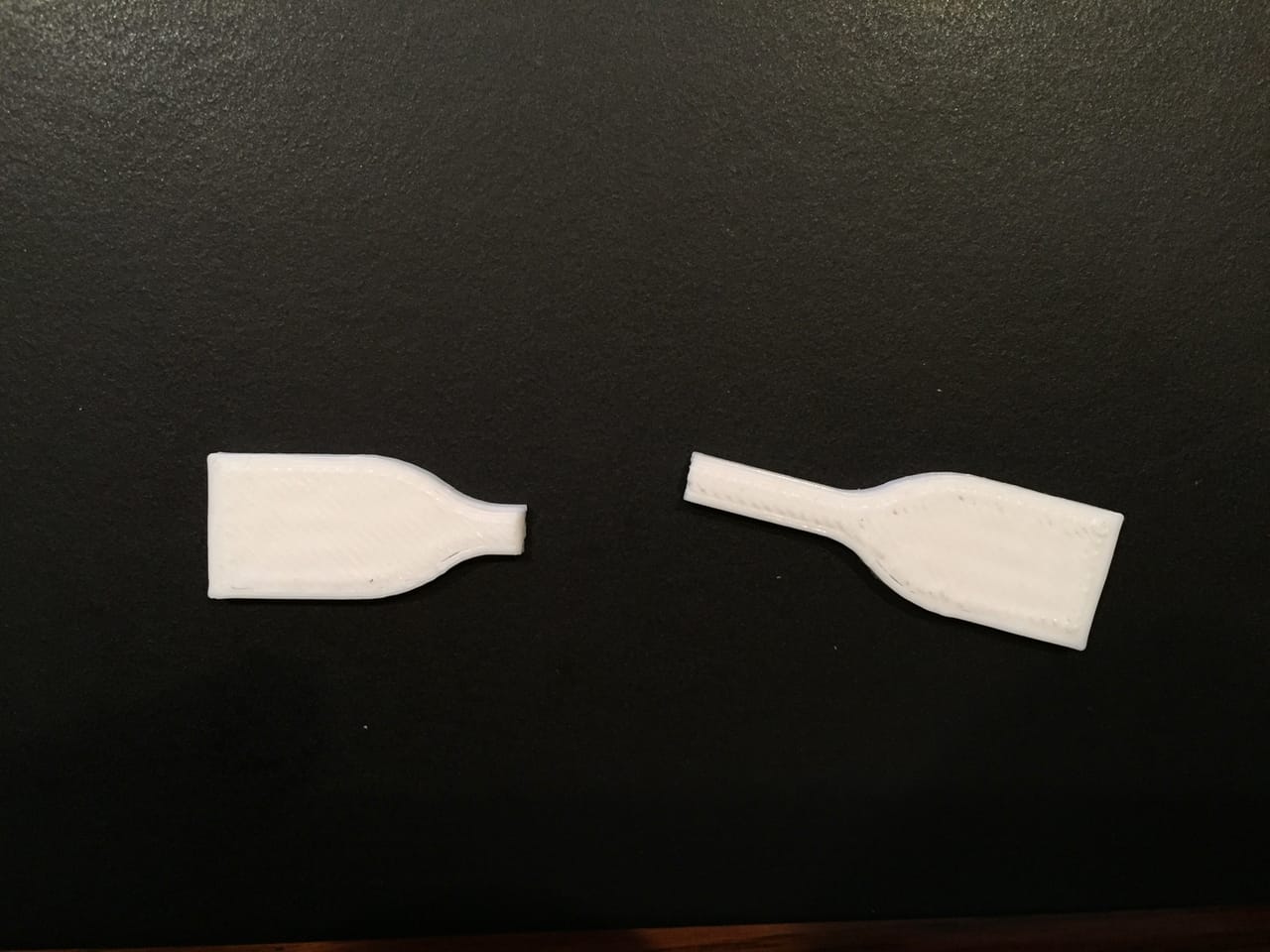

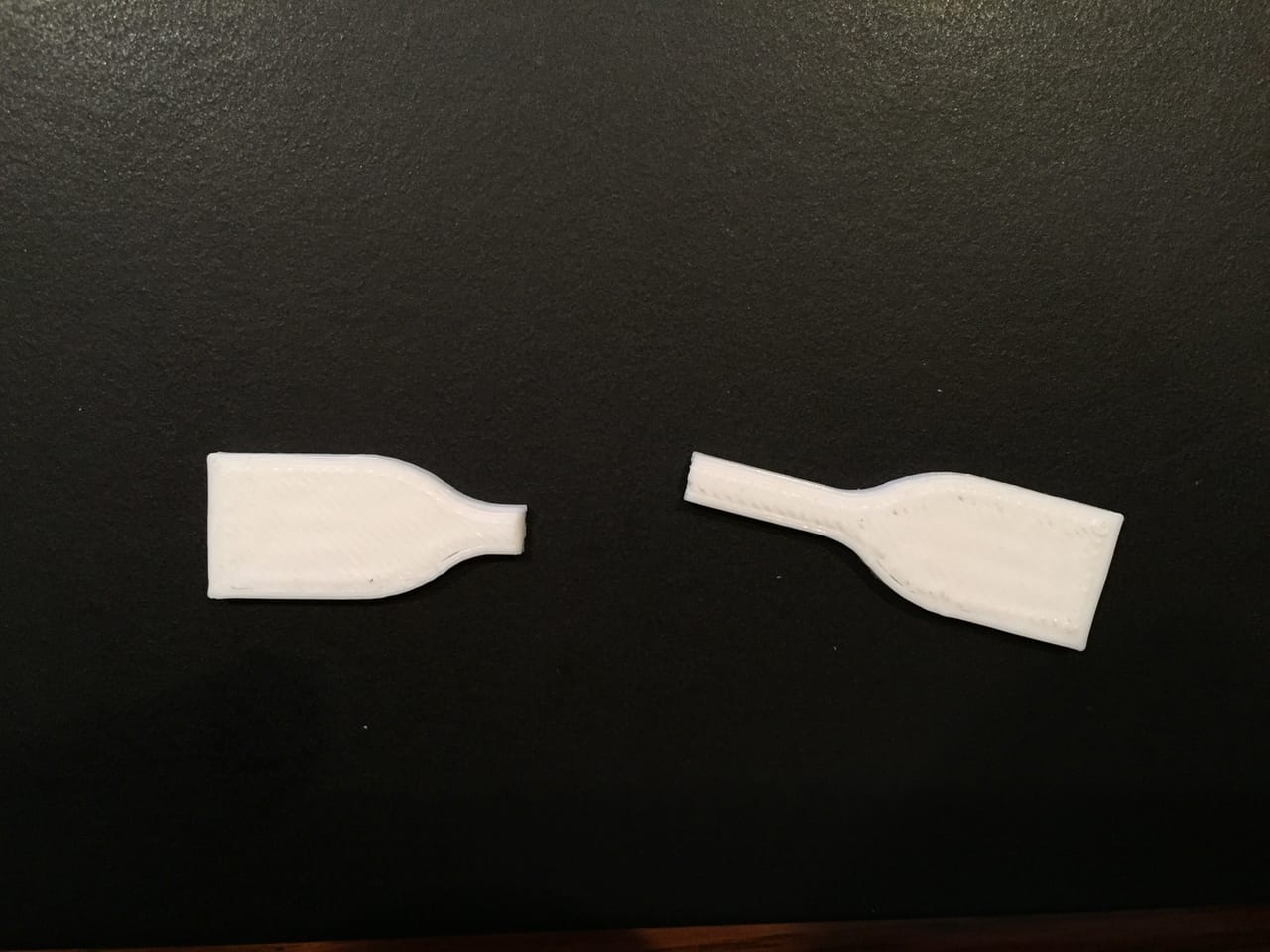

Orientation: 3D printers using the extrusion process print in layers, where the boundaries between them are the weakest point in the print. While it’s not possible to change the direction of printing arbitrarily throughout the model, you can choose the overall direction of the layers by orienting the model before printing. The idea here is to examine the likely directions of mechanical stress when using the print and then orient the model appropriately so that the weak layer boundaries are not so exposed.

Better Material: Another obvious approach is to simply choose a material that is stronger. Instead of using PLA, for example, choose ABS, or Nylon. This works if your 3D printer is capable of 3D printing alternate materials, and remember that some newer materials require specialized high temperature capabilities found only in select machines.

Composite Material: A class of 3D print materials has emerged that involves combining “normal” polymers with stronger materials. You can, for example, acquire spools of polymer filament infused with carbon nanotubes, glass fibers or other strengthening agents. The resulting prints won’t be as strong as the infused material alone, but they will be stronger than simply using the polymer.

Interior Injection: This is an interesting approach that we wrote of several years ago, in which a mostly-hollow 3D print is injected with a strengthening agent after printing. Simply drill a couple of holes on either side of the part and then use a hot glue gun to inject an adhesive into the sparse interior of your print.

Plating: Electroplating plastic 3D prints is becoming a more popular practice, as it is relatively inexpensive and provides a simple way to make a part far stronger than its original polymer form. I’ve seen quite strong parts made from nylon plated with copper or nickel metals, which just happens to make the surface a lot more attractive and also impervious to some environmental effects.

Combinations: Some of these approaches can be combined to make even stronger parts. Imagine 3D printing a carbon fiber-infused part with 100% infill and then electroplating it with a nickel surface. You get the idea.

But do you need to do any of these to strengthen your parts? It all depends on your intentions for part usage. Some applications require very little strength, for example a visual prototype that sits on a desk and looks good. while others, like a bicycle chain gear, will undergo lots of mechanical stress.

Start with your intended application and choose appropriately.