France-based Prodways has been around for many years producing high-end industrial 3D printers, but now they’ve released a less expensive model that is quite interesting.

The new P1000 is an SLS-powered device, in which fine plastic powder is selectively sintered by layer into fully formed 3D objects. Typically such equipment costs well over USD$100,000, making it prohibitively expensive for some businesses.

And those machines most often require the use of proprietary plastic powder material sourced from the printer manufacturer, making the device’s operational use even more pricey.

The new P1000 is priced at under USD$100,000, making it one of the least expensive industrial SLS machines available today.

There are a couple of new market entrants developed very low cost desktop SLS machines that are working in the sub USD$20,000 market, but they may not have the features and reliability of an industrial model like those from Prodways.

The P1000 offers a reasonable build volume of 300 x 300 x 300mm, and can print in layers down to 0.06mm, which should result in very finely detailed prints.

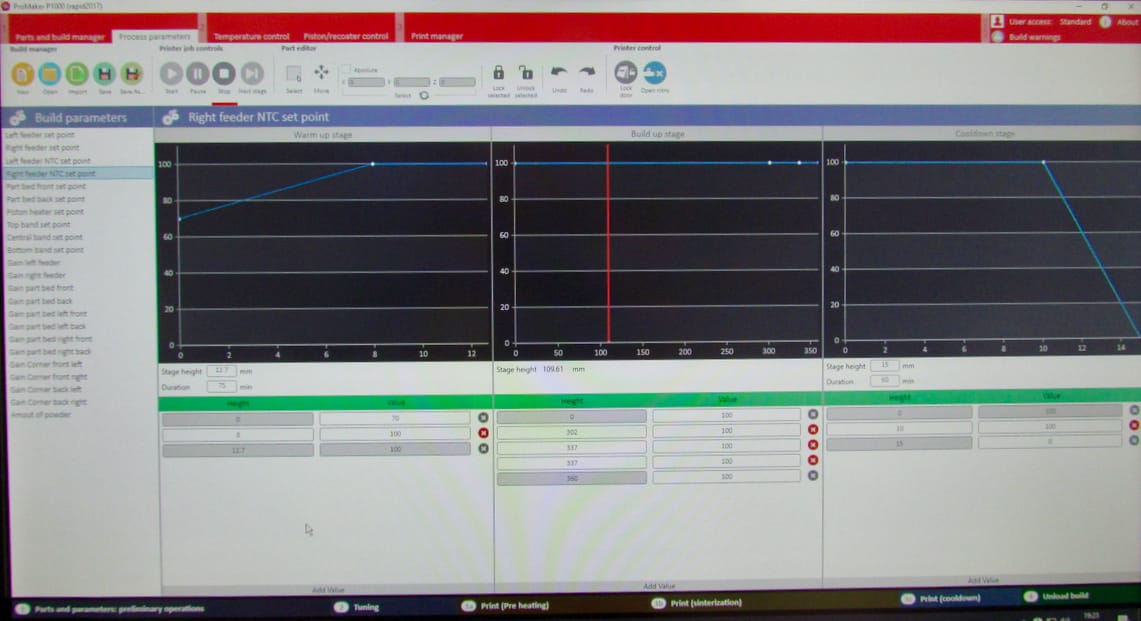

The machine will be reliable as well. It includes no less than ten independent heaters to ensure an entirely even and well controlled heating of the build chamber, critical for print reliability.

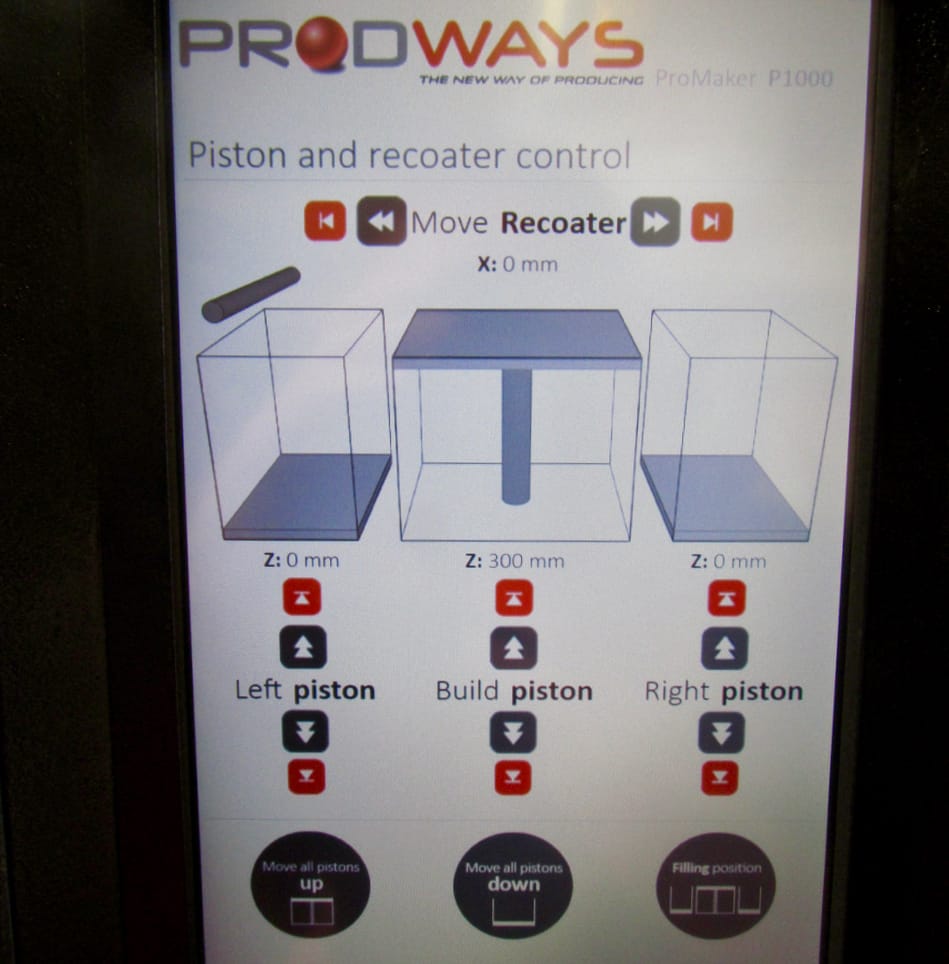

One of the interesting features of the P1000 is its recoater system, which is used to apply a fresh layer of powder for sintering during printing. Normally an SLS – or any powder-based machine – has a piston filled with powder. An application arm sweeps powder from the top of the piston and pushes it onto the build area to form the new layer.

However, the P1000 has TWO pistons. In this way the application arm can sweep in one direction and then stop. For the subsequent recoat, it then moves back, drawing powder from the second piston.

This may seem like a small thing, but consider that it reduces the amount of arm movement by a factor of two. And that arm must move across the print surface on each and every layer of the print. Thus, this is a pretty speedy SLS printer.

The company says the machine is designed for ease of use, and I don’t doubt it, judging from the fancy control panels shown on the machine.

The P1000 typically will 3D print in nylons and TPU plastics, but the company proudly offers an “open materials” option, unlike some other SLS 3D printers. Prodways has a way for you to use “unusual materials” in this machine.

This is quite important, as it enables operators to experiment with unusual materials, or even mix them together to form composite materials. Of course, there will be experimentation taking place to get them to work, but it is an option.

The other benefit of open materials is that it enables 3D print operators to potentially lower their operating costs by purchasing third party materials at discount prices.

I can’t help but think that Prodways might have been prompted to produce this relatively low cost machine by anticipating the development of lower cost options.

It’s a good move for Prodways, and also for their customers.

Via Prodways