Surprise! Formlabs has suddenly announced a new 3D printer, and it’s entirely different from anything they’ve previously produced.

The machine is called the “Fuse 1” and it is NOT an SLA 3D printer, as all their previous products have been. No, instead this is an SLS machine.

The SLA machines they’ve grown with, the Form 1, Form 1+ and Form 2 all use lasers to selectively fuse liquid photopolymer resin into solid objects.

The new Fuse 1 doesn’t use resin at all. Instead it uses powder. However, there are lasers involved.

The laser in the Fuse 1 is used to selectively fuse layers of fine plastic powder into solid objects. In a way, the process is very much like the Form 1 and 2 process, as a laser must sweep across the build area on each layer.

But that is where the similarities in process end. The powder is spread across the build area in successive layers, where the final 3D object ends up buried within a build volume filled with powder.

While it may take minor effort to extract the completed object from the powder, there are significant advantages to this process.

The first advantage is that the powder automatically supports the model during printing, as all solid parts are surrounded by unfused powder. This means the SLS process can 3D print highly complex objects without need for support structures and far fewer geometric constraints.

The second major advantage is that different materials can be used. In the Fuse 1, Formlabs has introduce a pair of nylon powders that can be used to 3D print very strong objects, stronger than is achievable with Formlabs’ other equipment.

While they initially offer powdered nylon, I expect them to gradually introduce new powders over time, making the Fuse 1 even more powerful.

One feature present on the Fuse 1 that puts in the industrial class is the removable build chamber. This enables operators to rapidly swap in a fresh build chamber to continue printing as much as possible, while the used chamber has its parts extracted at leisure elsewhere. Typically a build chamber will have multiple parts loaded into it, 3D-tetris style in order to more efficiently use the machine. This should raise the efficiency of the machine considerably.

We don’t yet have full specifications for this device but judging from the images it would seem the build volume of the Fuse 1 is small to medium-sized, sufficient for many applications.

There is an image of an onboard camera, suggesting that the Fuse 1 provides some level of remote management, as is seen in many industrial 3D printers these days.

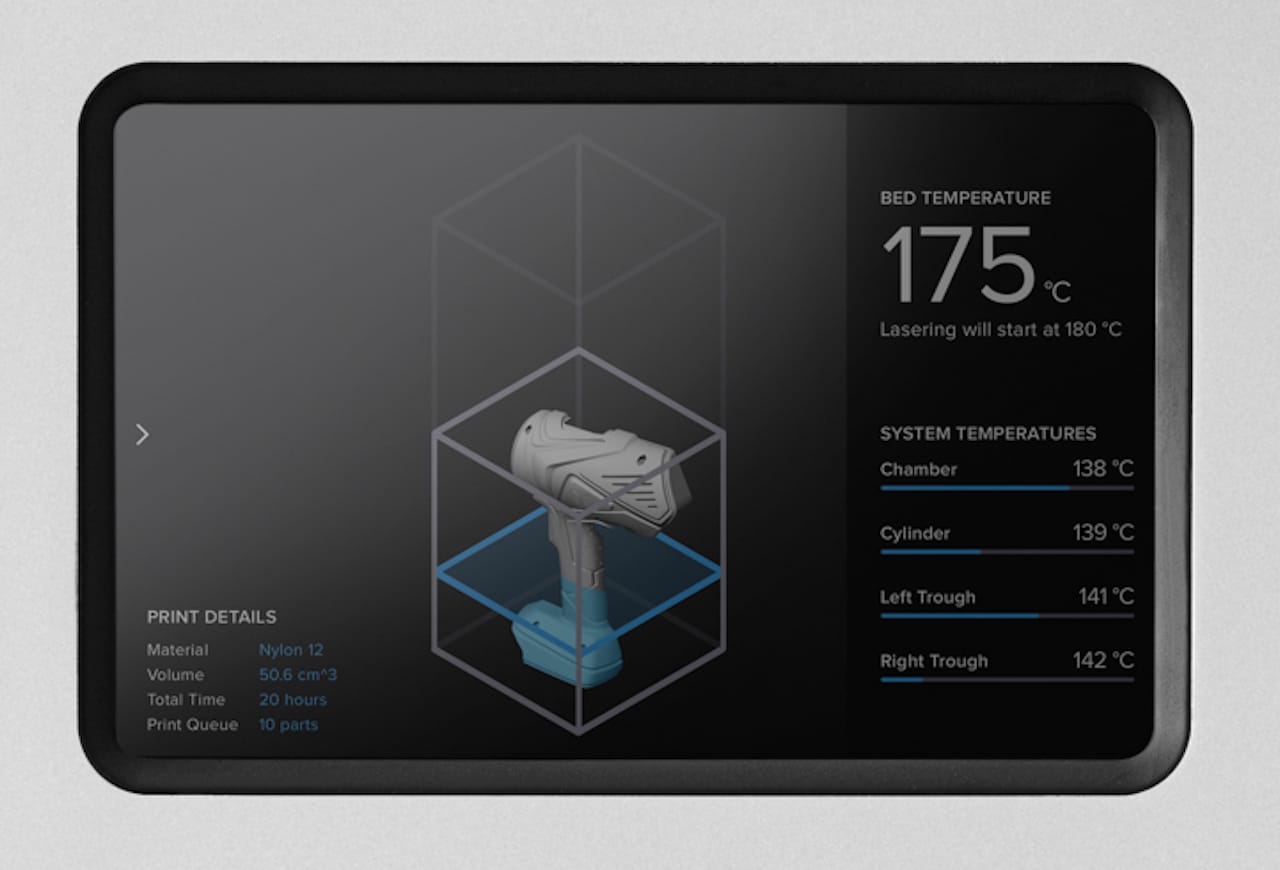

One thing that is certain, however, is the user interface, which is visible on some of the images, as shown here. The Form 2’s interface is simply one of the easiest and beautifully created we’ve seen on any 3D printer, and it appears that the Fuse 1 offers something similar. The Fuse 1 will no doubt be a pleasure to operate.

The machine is available for pre-order with a USD$1,000 deposit, but it won’t ship until some time in 2018.

There’s one other fact we’re aware of: the price. The price of this machine is extremely attractive at USD$9,999 for the printer. Formlabs also offers a USD$19,999 bundle that includes a finishing station along with the printer itself, which is likely what most customers will purchase.

This pricing is significantly less than the options available from the SLS market leaders, EOS and 3D Systems, but comparable to the pricing offered by a couple of SLS startup companies seeking the same market as the Fuse 1. It’s not clear which company will dominate this segment, but I do know that Formlabs has deeper pockets based on their several rounds of major investment over the past few years and a far larger sales and distribution network.

This machine is quite a departure for the still-young company, and signifies a strategic change. I’ll discuss this notion in a future post.

Via Formlabs