With yesterday’s announcement of new MakerBot tools for educators, it is now very clear what the original desktop 3D printer company is pursuing.

Being in existence since 2009 means the company has seen literally the entire scope and evolution of desktop 3D printing, from its wild and promising beginnings, to the absurd heights of media attention, to a market collapse, and more recently, a resurgence in particular areas.

Along that path they’ve had to navigate towards profitability, and that’s been very challenging. Why? Because until recently it wasn’t clear where this technology would succeed. What were desktop 3D printers good for?

There was a time when it was thought (or at least excessively promoted) that desktop 3D printers would be a consumer device. The phrase “A 3D printer in every room in your house” could be heard, although I have no idea why you’d put one in your bedroom, with potentially toxic emissions.

But that was the struggle of the time: what would these things be good for? Many experiments took place, some by MakerBot, and many by countless other companies, some of which are no longer with us.

But now, in mid-2017, it is slowly becoming clear which uses are indeed practical for desktop 3D printers. They seem to be used successfully:

- In education to enable students to understand design and build processes

- By a relatively small market of DIY designers, artists and makers for personal projects

- In industry for manufacturers to produce helpful and productive jigs and fixtures

- In professional offices to iterate through prototypes to arrive at a design

The second item, the DIY market, is where MakerBot originated. While they dominated it at the beginning, they have been overtaken by a number of innovative smaller companies today who sell far more units than MakerBot.

The latter two, manufacturing and prototyping, are very interesting and perhaps the biggest growth area in desktop 3D printing today. What’s been powering that surge is the recent development of high-temperature desktop 3D printers that are capable of printing in materials more familiar and useful to engineers, such as PEEK, carbon fiber, nylon and others, often with water soluble supports enabling perfect prints of complex geometries. The idea is to make prototypes that are a lot closer to the performance of the final design.

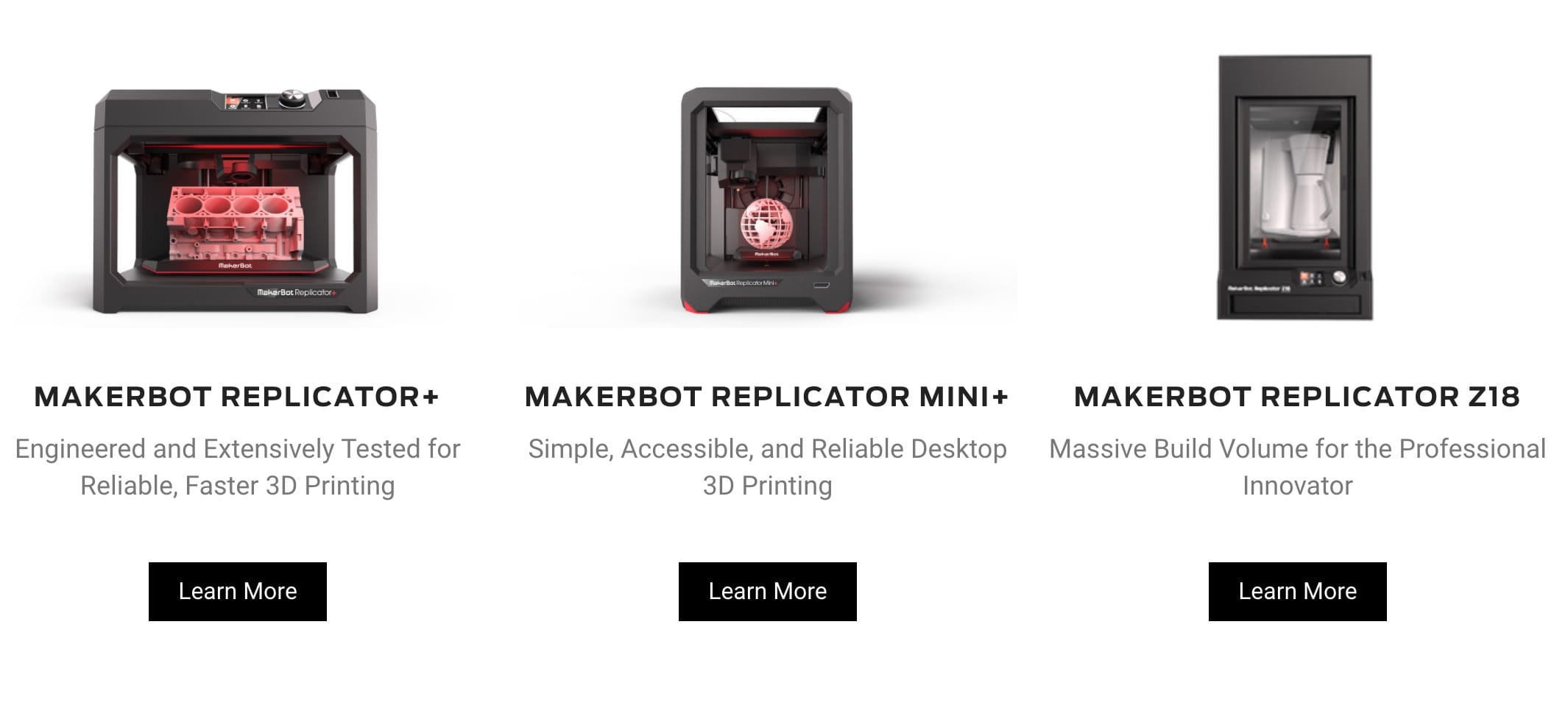

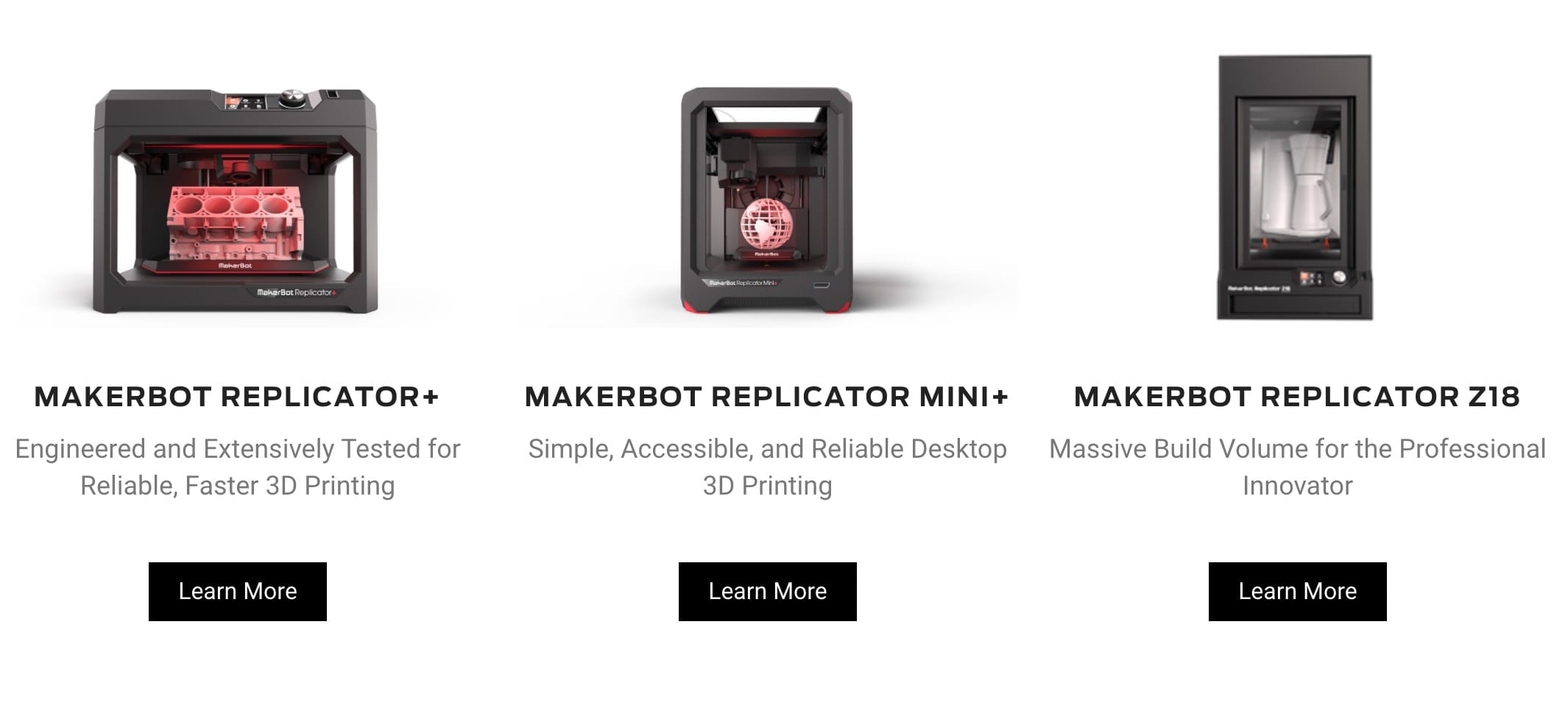

But there’s a problem there for MakerBot. Of all the major desktop 3D printer manufacturers, MakerBot is the only one that has not developed this capability. With one exception, their entire product line, including all models announced in the past three years, can 3D print only in PLA plastic. And PLA plastic is simply not sufficient to hit those latter two markets.

I’ve heard no buzz that MakerBot is developing a new 3D printer capable of 3D printing advanced materials, while their aging Replicator 2X was announced going on FIVE years ago, and might be facing discontinuation sometime soon. It has been overtaken by better alternatives from many other companies.

This leaves but one major market target possibility for MakerBot: Education.

And that’s why we saw their announcement this week. Expect more educations stuff to come from MakerBot in coming months.