MakerGear has introduced a terrific new feature in their latest desktop 3D printer, the M3.

MakerGear is one of those legendary desktop 3D printer manufacturers that was there right from the beginning many years ago. The company began as a hobby and turned into something far grander over time and now is one of the most reputable makers of desktop 3D printers. You can read the story of their founder, Rick Pollack, here.

The company began years ago with rudimentary 3D printer designs, but they had a feature many machines did not at the time: they actually worked. That, combined with a friendly and reliable service attitude led to their success today.

In 2012 the company introduced the MakerGear M2, which has been upgraded numerous times and was essentially the flagship product for the company. A great many M2’s were sold and still run around the planet.

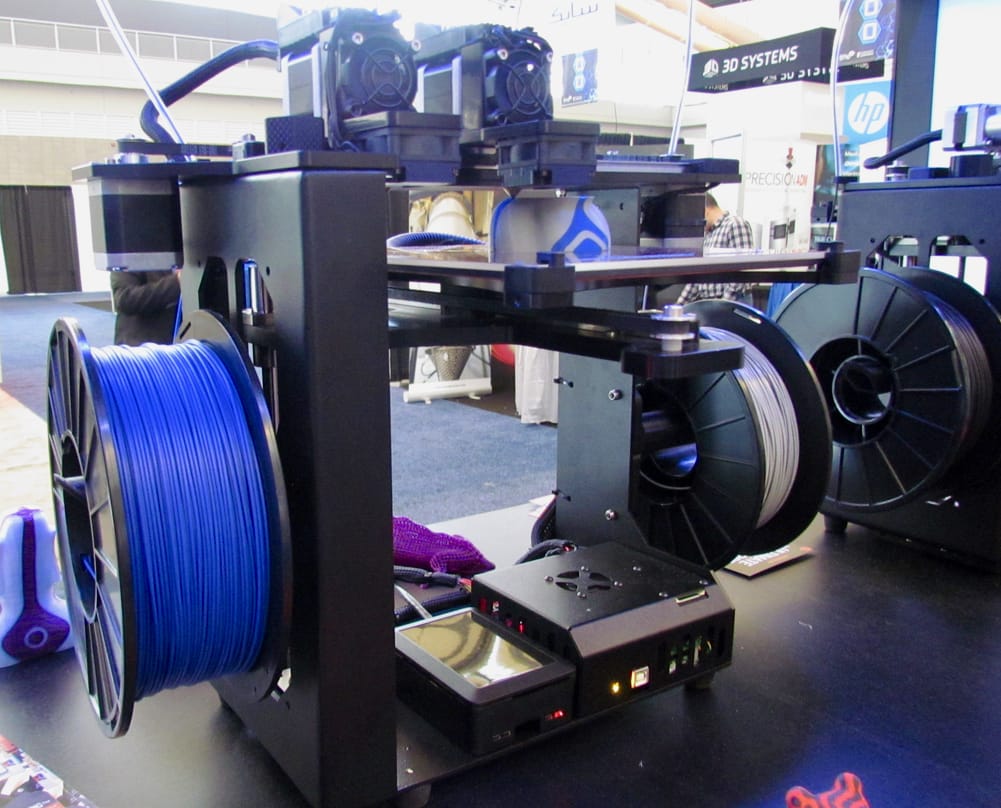

But now the company has introduced their most powerful machine yet, the M3.

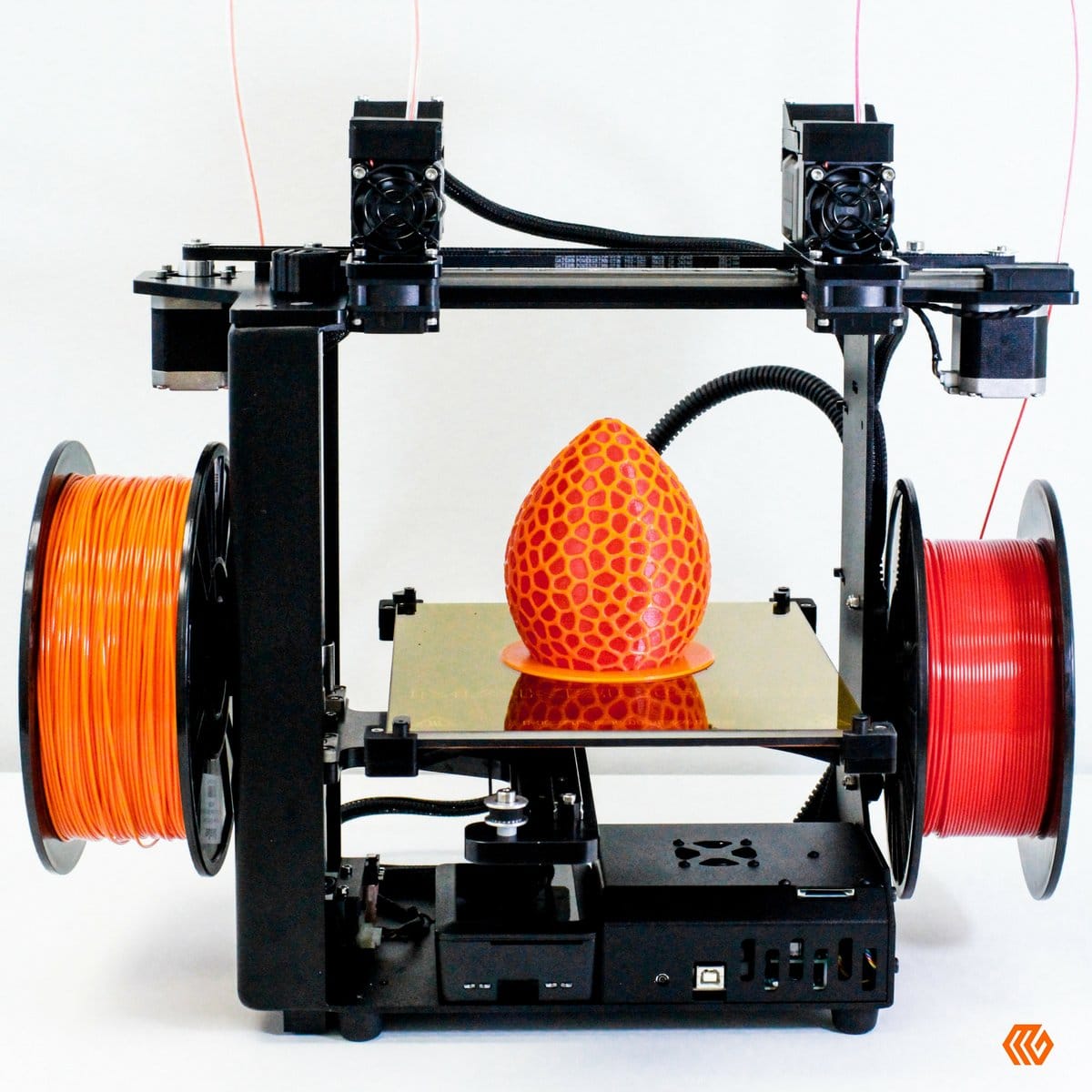

Like it’s predecessors, the M3 is an open format desktop 3D printer (unless you’re using the optional enclosure) using the extrusion process. It includes all the refinements that were engineered into the M2, but with a big surprise feature.

But the basics first: the M3 has a generous build volume of 203 x 254 x 203mm, and uses 1.75mm filament. The minimum layer size is only 0.02mm, much finer than most desktop 3D printers, which frequently quote 0.05mm as their smallest layer size.

The build plate is heated up to a huge 130C, and the hotend can hit a high 300C, meaning you can successfully 3D print ABS, HIPS, Nylon, PET-G, PET-T, PLA, polycarbonate, PVA, TPE,

TPU, metal composites, wood composites, carbon fiber

composites, and more.

These materials are helped by the available stainless steel nozzles that can complement the standard brass models. And you can swap in larger or smaller nozzles to optimize for fine detail or fast printing.

All these different materials are even easier to print as MakerGear has prepared a database of material profiles that you can immediately use. It’s also possible to develop your own material profiles and save those for future use.

The M3 includes the usual SD card and USB interfaces, as well as WiFi and ethernet connectivity. Through these last two you will be able to remotely monitor the print operations with a future kit.

Unlike some machines, the M3 does not include an automated leveling system. however, it does include “assisted leveling”, which should make the process far easier.

MakerGear has used the open source Octoprint system to provide a very cool and sophisticated interface to the printer. It provides a graphical way to operate the 3D printer through the internet via a web interface.

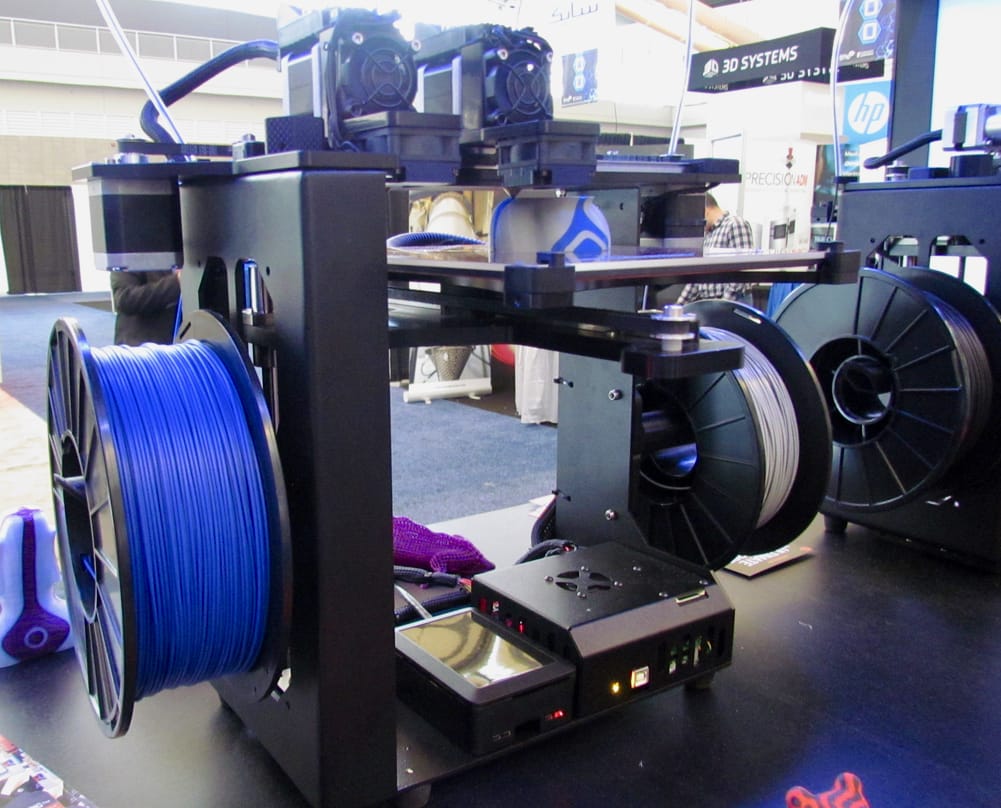

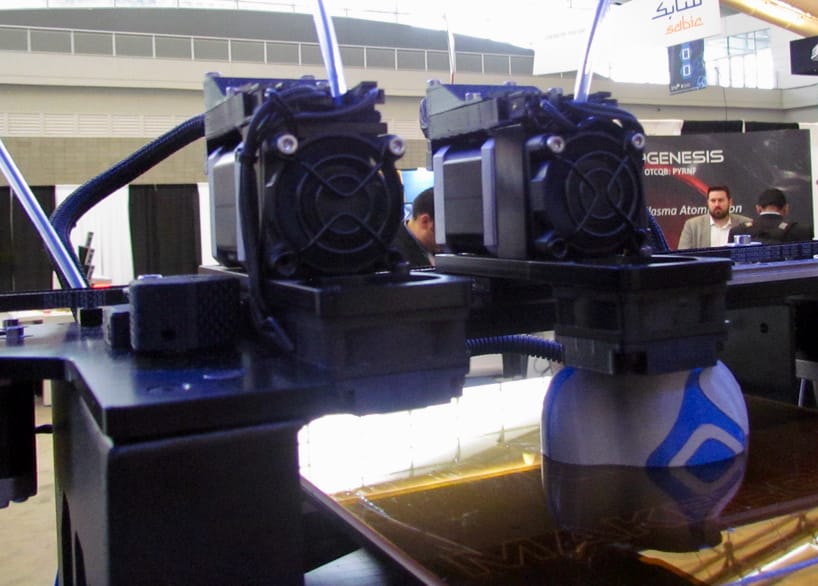

That’s all great, but the big new feature is “independent dual extruders”. These are independently moving extruders that can print a single object twice as fast or print two completely different objects simultaneously. Or print two copies of the same object. You get the idea.

There are not very many 3D printers that have this feature, only three I believe at this time. Nevertheless, they provide a great deal of additional power and flexibility to a desktop 3D printer, especially one that can print in so many different materials.

While you can certainly print two-color models with this arrangement, it’s far more likely the second extruder would be used for water soluble support to enable successful 3D printing of highly complex 3D model geometries.

The “M3 Independent Dual” will be shipping in July, but you can pre-order one now at a discounted price of USD$2,999. And don’t have concerns because this machine comes with a full 12 month warranty, unlike almost every other desktop 3D printer.

Via MakerGear