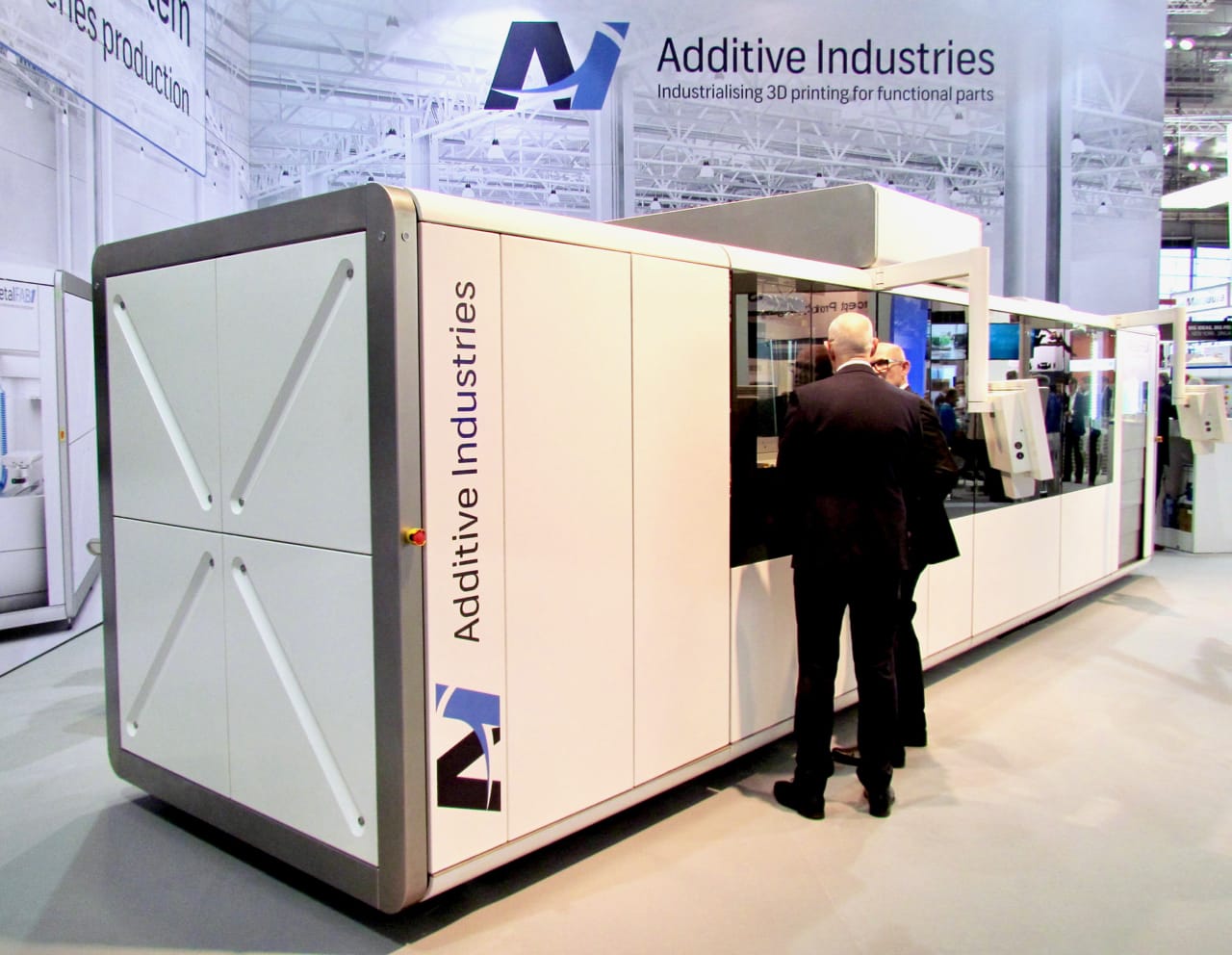

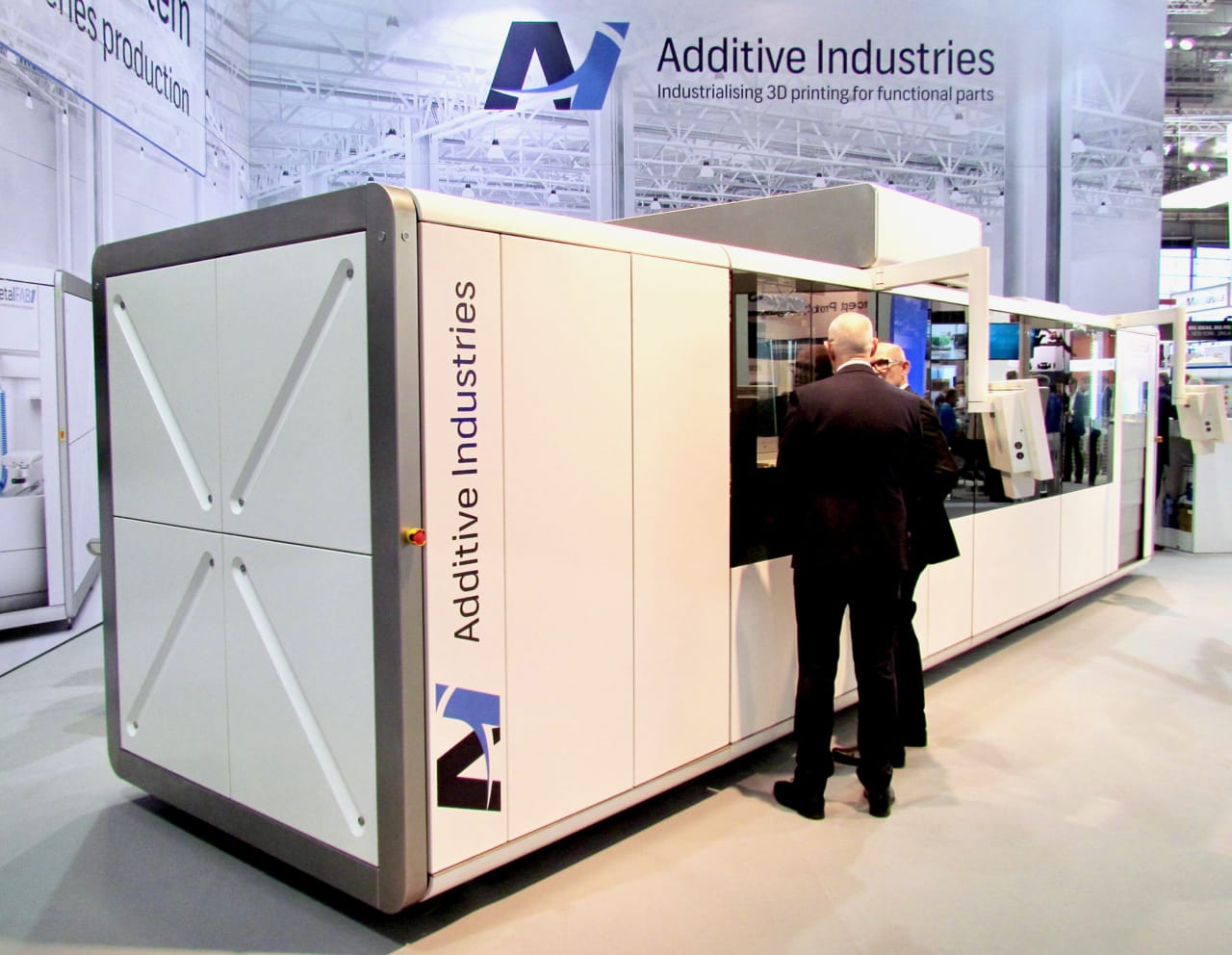

Netherlands-based Additive Industries announced a powerful upgrade to their 3D metal printing system.

The company produces the MetalFAB1, an integrated system that includes multiple subsystems to handle the difficult process of 3D metal printing. While most 3D metal printers do only the “printing” itself, you must separately handle the powder, build plates and heat treatments, all of these functions are included in the MetalFAB1. Even better, they are integrated to work together smoothly, providing a proper manufacturing system.

But Additive Industries faces competition from a number of other 3D metal providers, some of which have chosen to focus on print speed, while others are attempting to address the operational process efficiencies, such as those implicitly provided by the MetalFAB1’s integrated approach.

The speed factor is an interesting problem for vendors using the laser / powder bed fusion approach. To print faster, you can raise the laser power, making the powder melt faster, enabling the laser to move more quickly to complete a layer of the 3D print.

You can also do something obvious: add more lasers! And that’s exactly what some 3D printer manufacturers have done. Multiple lasers can 3D print in parallel, making the effective print speed several factors faster.

And that’s precisely what Additive Industries has done: they’ve upgraded the MetalFAB1 to include not two, but four lasers to dramatically increase the print speed.

Even better, they say they will later this year raise the fiber laser power from 500W to 1KW, doubling the power. This should also significantly speed up 3D printing operations.

I think this is a very strategic move, as it counters the feature upgrades coming out from their competitors, who have yet to develop comprehensive process integrations as are already present in the MetalFAB1.

But they’re working on it. Meanwhile, I expect Additive Industries to come out with further enhancements to keep their lead.