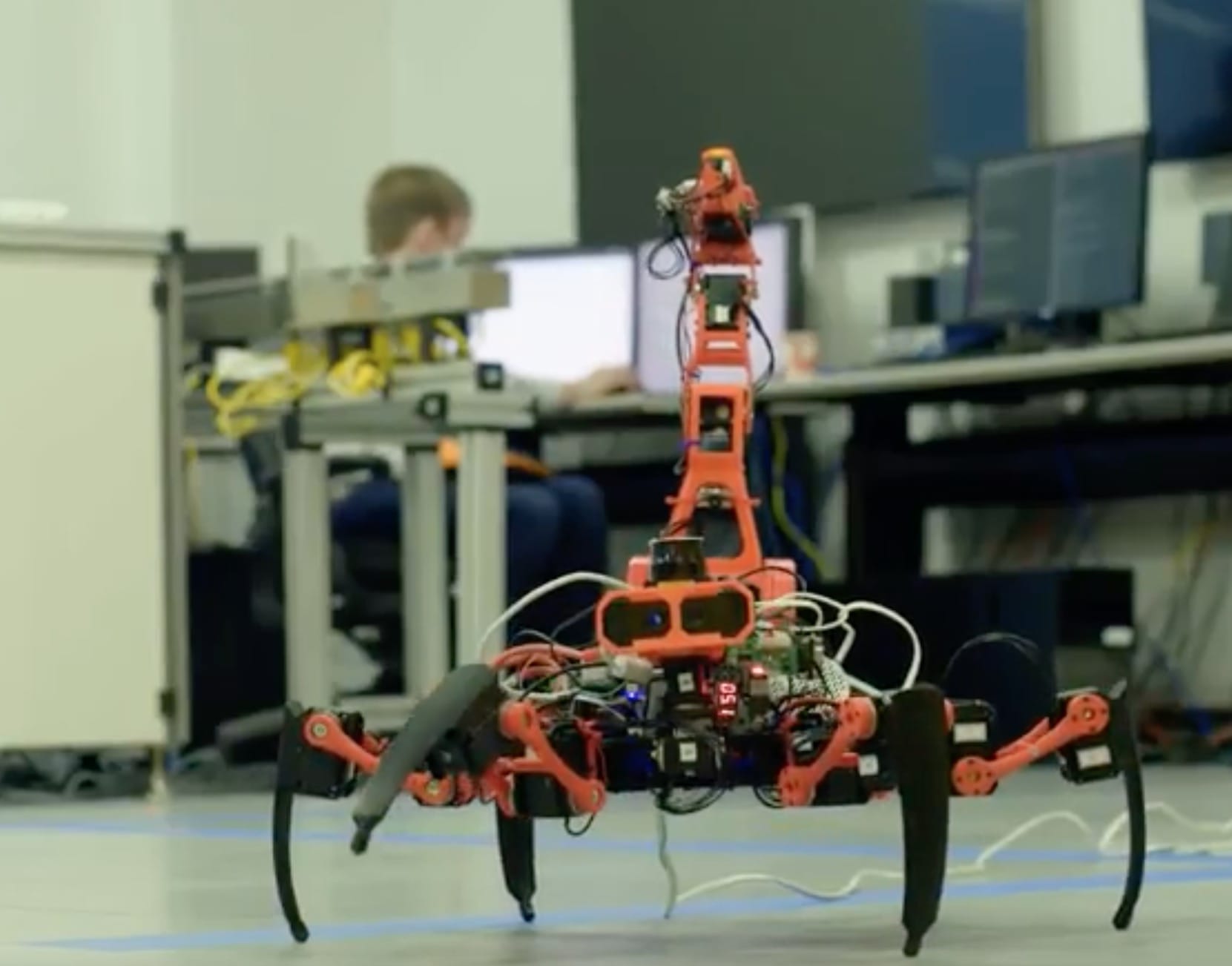

A report on Forbes details work undertaken by Siemens to develop a “mobile robotic 3D printer” concept.

The curious-looking small robot was developed last year and since then has served as an experimental platform for developing software for future production use.

What kind of software? It seems to be about a different way of manufacturing.

In today’s manufacturing world powered by robots, the machines require careful planning and setup to accomplish their assigned tasks on the assembly line. Essentially they are programmed to do their specific work, all of which should be within the effective range of the robot’s arms. And that’s all they do until programmed differently.

The new concept apparently being experimented with is a bit different. Forbes writes:

But some day, the same software that is helping the robotic spiders crawl the floor while avoiding obstacles and keeping their printing parts in balance could enable whole new systems of factory work – on tasks much more complex than assembling handheld toys.

Hasan Sinan Bank helped develop the first walking, talking 3-D printer from Siemens. He uses it to test out new kinds of robotics software.

For example, a team of robots could work together on a new kind of fuselage cylinder for airplanes, Bank says. If each robot could attack the job from a different angle, they might build complex shapes together that no single printer could create by itself.

This is a fascinating concept: imagine a “swarm” of small units crawling over, under and within an object, all building portions of the final product simultaneously. One wonders what kind of speedups you could achieve if you could deploy large numbers of such builder units?

But that’s an extremely difficult concept to attain in reality: today’s robots have the significant advantage of being stationary, where things within their scope of operation are largely predictable. That’s definitely not the case when the robots are moving around, changing their “landscape” from moment to moment. Even more complex is the issue of encountering other builder robots, where decisions on what to do would have to be made dynamically. I’m not even going to think about the probably endless failure modes that would have to be detected and handled in some way.

The more you think about it, the more Siemens’ experiment makes sense: get some robots on the shop floor and get experience. Learn how to move about, how to avoid obstacles, how to recognize things.

Once these basic functions are learned, then they can turn their attention to the matter at hand: manufacturing.

Via Forbes