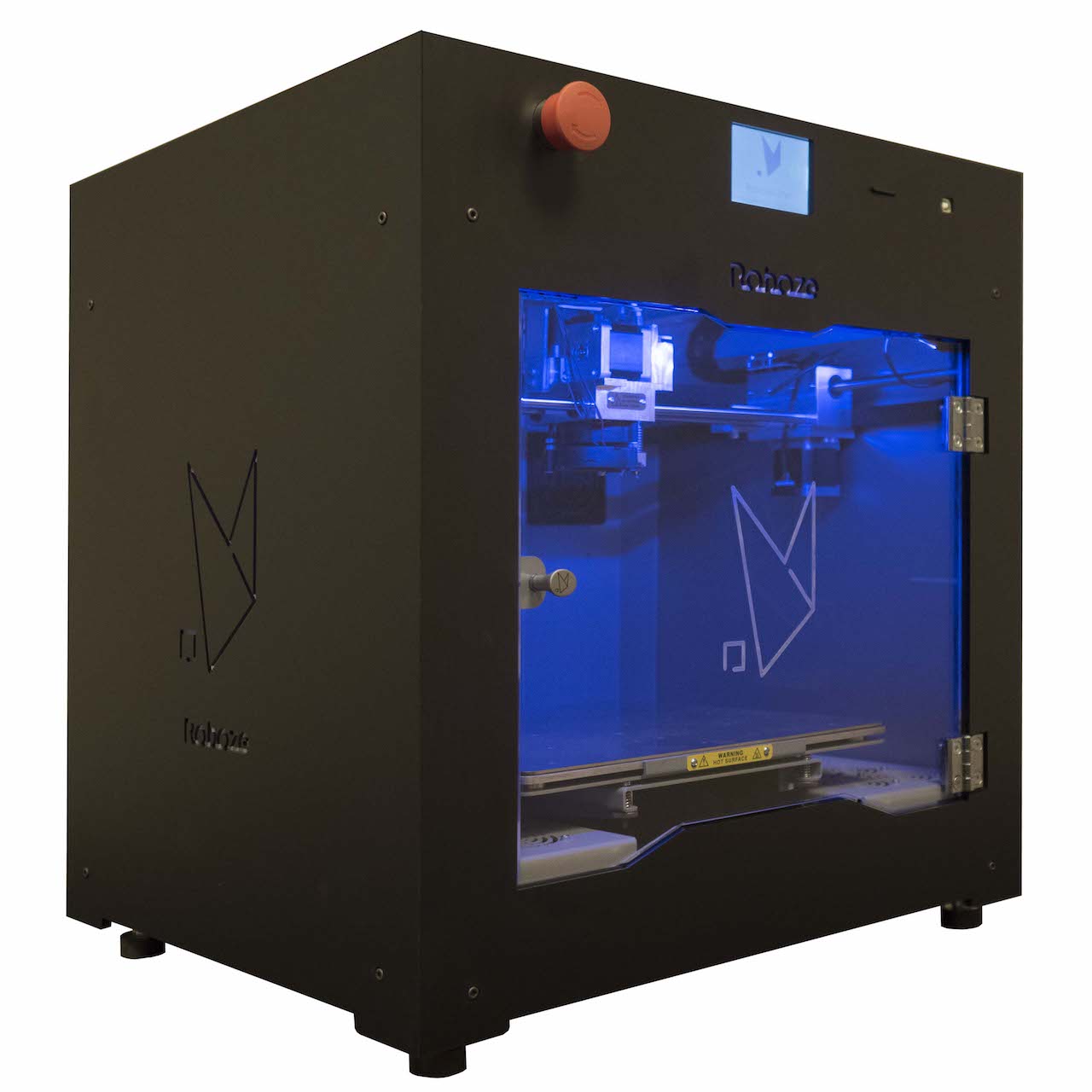

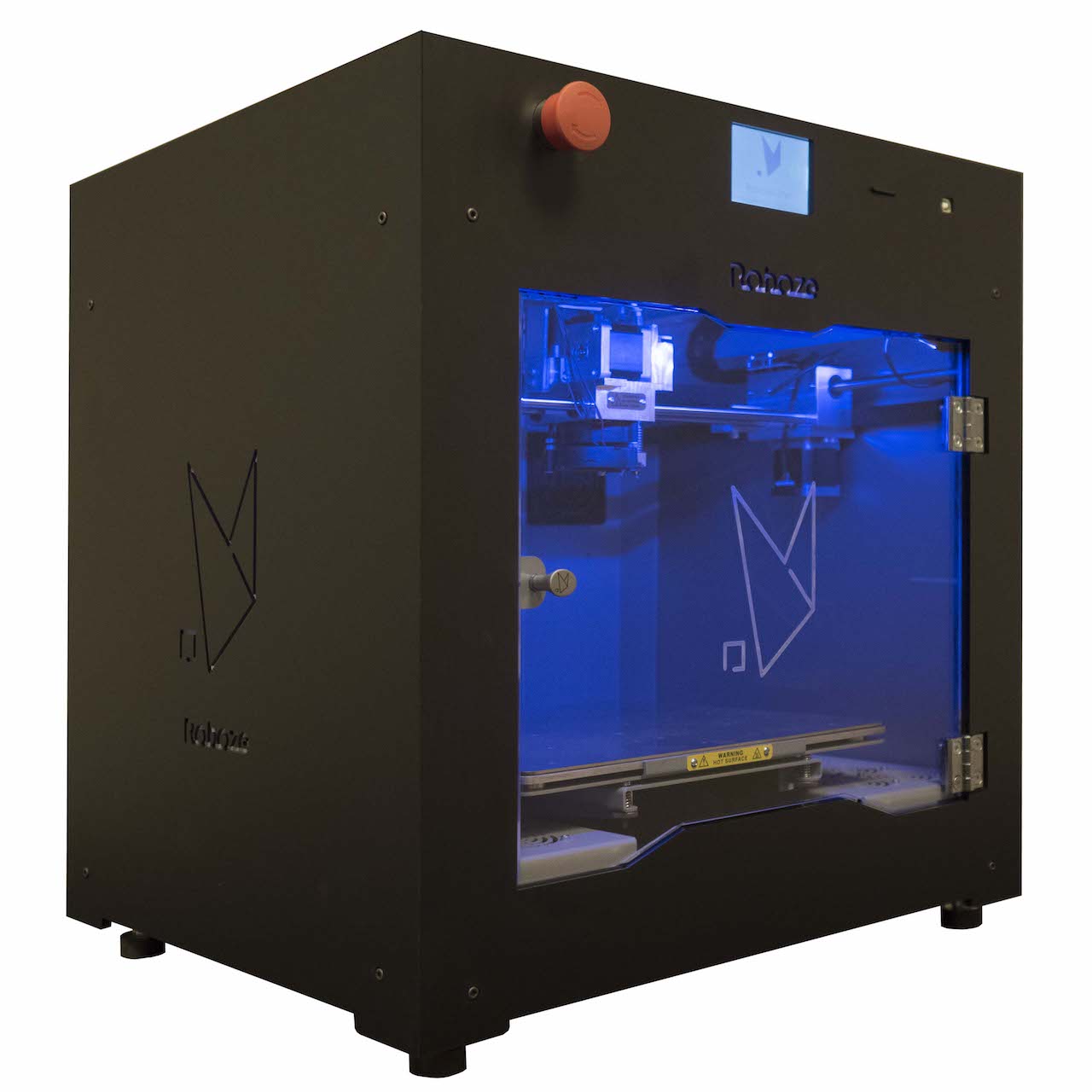

Roboze is an Italian company focusing on high temperature desktop 3D printers, and today they’ve released their most powerful unit yet.

The New Roboze One is a few steps up from their previous model, but still leverages the key technologies that permit high temperature 3D printing, most notably their complete lack of plastic belts for the mechanical system.

In almost every 3D printer you can name, plastic belts are used to drive the print heads around the build volume. The catch is that machine designs invariably include these belts within the print chamber itself. This is normally not an issue, but it becomes one when you attempt to print in high temperatures. Why? Because the increasing heat in the build chamber can affect the belts themselves – either diminishing their useful lifetime or distorting their shape, which results in poor quality prints or even print failures.

That’s not the case in Roboze equipment.

Now, what have they done with the New Roboze One? (And yes, “New” appears to be part of the product’s official name).

There are several very important improvements in this machine, so lets start with the resolution.

The machine is apparently capable of plastic extrusion 3D printing in layers as small as 0.025mm, or 25 microns. This level of resolution has been achieved previously in a few well-tuned other extrusion 3D printers, but as far as I can tell, not with any other machine operating at high temperatures. This could make the New Roboze One the most accurate high temperature 3D printer you can obtain today.

The mechanics of the machine have been upgraded in such a way to reduce vibrations, which as you might imagine would be challenging when printing at such fine resolutions.

Roboze has also upgraded the hot end on the New Roboze One to be entirely made from metal. The stainless steel hot end here, should permit temperatures of up to 300C, making it possible to 3D print even more high temperature materials.

And wouldn’t you know it, but Roboze simultaneously announced the availability of a number of new high temperature materials, including these from their press release:

- CARBON PA, engineered polymer for Roboze customers with polyamide base, 20% reinforced with carbon fiber;

- Nylon 6, polyamide with high mechanical resistance, used to print components in the field of metalworking;

- ASA, techno-polymer with high weather, UV rays, yellowing and aging resistance, which makes it perfect for automotive components and outdoor applications;

- PC-ABS mixes PC mechanical properties and ABS high workability, making the printed parts not only perfectly defined but also with a great surface finishing;

- ABS-HD, combining ABS mechanical properties with a strong level of superficiality, is used for post production operations;

- ABS-ESD, which is an advanced polymer with ABS base modified according to a proprietary formulation with carbon nanotubes and process/ loss modifiers, perfect for measurement and survey applications, HDD components, envelops and connectors.

The machine also includes an upgraded color touch screen for easier operation.

I believe this is a very strong move by the Italian company, as it is my understanding that the most requested feature of professional desktop 3D printers these days is the ability to print very specific materials. Engineers developing products want to 3D print prototypes in materials as close to the final product as they can, and 3D printing in ABS and PLA just doesn’t cut it in many cases. With a machine like the New Roboze One designers will have a great deal more flexibility to 3D print in materials of choice – and in high resolution, too.

Via Roboze