There are plenty of vendors of common 3D print materials, but far fewer offering unusual composite materials.

One of them is Italy-based Windform, who produce a series of exotic powdered materials for selective laser sintering (SLS) 3D printers. They’re associated with CRP Technology, one of the largest 3D print services / rapid prototyping companies in Italy today. They’ve developed the materials and now market them through Windform.

The idea is that the print service receives requests for specific engineering characteristics from clients, and their research and development department then goes about developing a custom material to match. Over the 10+ years they’ve been doing this, they’ve accumulated a wealth of unusual materials.

Today’s Windform product set (XT 2,0, SP, FX, GT, RL, LX 3.0, GF 2.0) includes materials that offer combinations of these characteristics:

- Lightness, strength and stability

- NASA-tested outgassing performance

- CNC milling capability

- Waterproofing

- Chemical resistance for certain substances

- Skin contact approved

- Ability to create breathable parts

- Non conductivity

XT 2.0, for example, is a carbon fiber reinforced powder with significant mechanical properties. SP is a carbon fiber reinforced composite polyamide, while GT is a glass fiber reinforced composite material. They even provide a flexible material, RL.

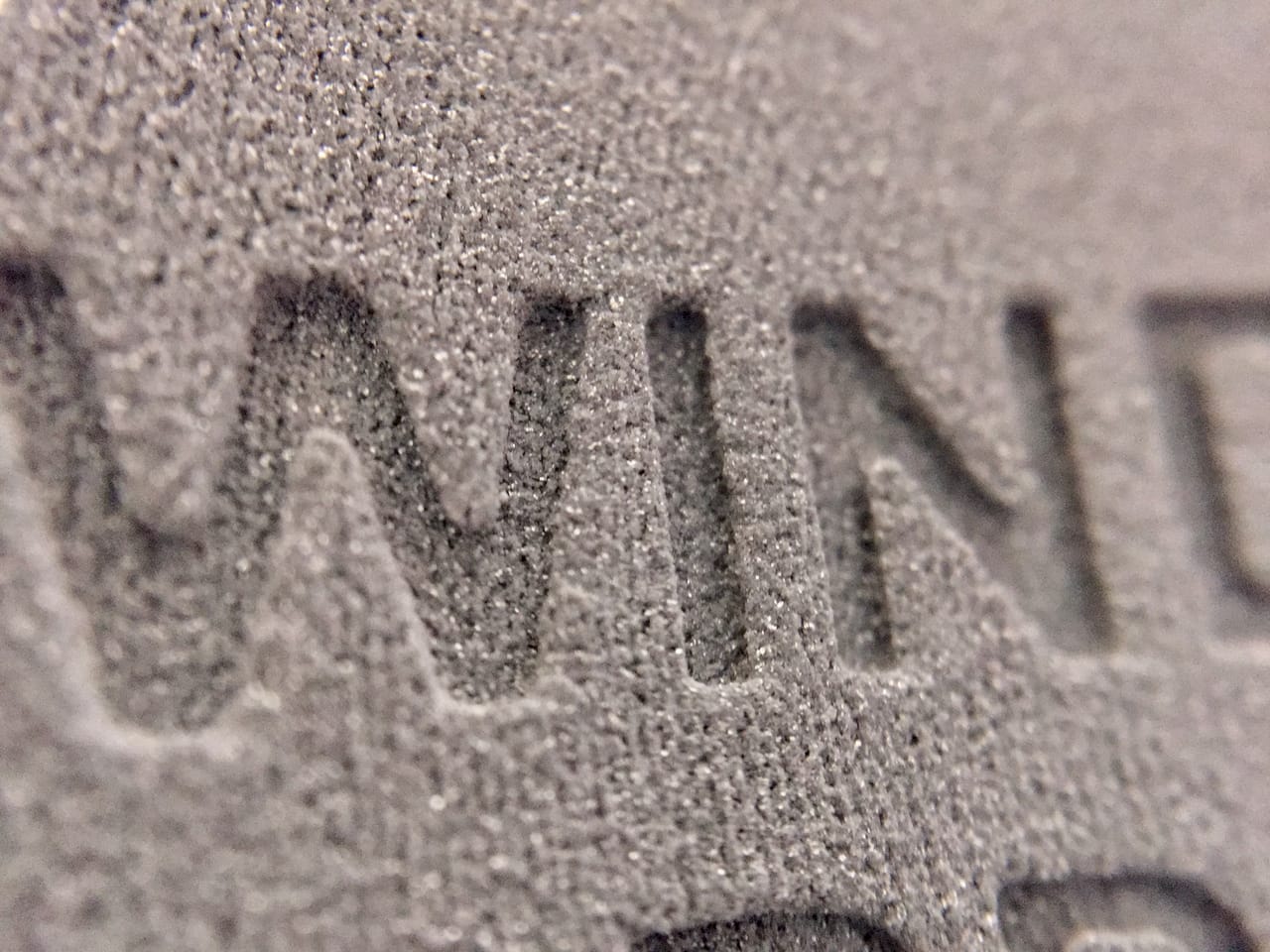

One that’s quite interesting is Windform GF 2.0, which is a polyamide mixed with glass fiber and aluminum, a sample of which is shown here. I can attest that this piece is extremely strong.

The Windform materials vary considerably in price. They’re sold in 120 Kg batches, with the most expensive material being Windform RL at €16,800 (USD$18,120). XT 2.0, a popular material, runs for €13,200 (USD$14,200) for 120 Kg. The least expensive Windform material is GF 2.0, which goes for only €7,440 (USD$8,000) for 120 Kg.

Of course, you can get reasonable discounts if you order larger quantities. These materials are really designed for workshops using larger quantities in continuously running equipment, so that’s likely going to be the case.

Are you operating an open-materials SLS 3D printer? You might want to consider using Windform materials for parts requiring unusual characteristics.

Via Windform