Are you 3D printing in metal? Thrinno’s new quoting system might be for you.

3D metal printing is a very complex and risky business, not so much that prints fail, but instead it’s because of the very high cost of 3D printing in metal. The metal powder used in most machines can cost up to USD$500/kg, making failures a very pricey experience.

The idea is to print successfully in as few iterations as possible. This means you should spend considerable time to carefully plan out the print, with not only the basics like print orientation, but also precisely setting the temperature and movement settings as well as the design of the support structures.

One of the most important analyses, one not found in plastic 3D printing, is that of thermal stress. The tremendous heat generated by the printing process is conveyed through the in-progress print, which may cause warping, damage or other material effects.

The goal is to have a print that not only looks good, but also has the correct internal crystallization and quality.

Thus there is great attention required when setting up a 3D metal print.

But most of the time users don’t operate their own metal printing equipment, due to acquisition and operational costs, but also due to the expertise required to properly set up and run the jobs. Thus a great deal of 3D metal prints are done through service providers.

And these service providers must interact with their clients to provide suitable quotes for such services. And that turns out to be a rather complex matter, for which there are very few solutions. One solution is Thrinno’s quoting system, which provides a complete, embeddable solution for 3D metal printing providers. They explain:

Getting to a successful print and a reasonable price is not only dependent on the orientation of the part on the build plate, but is also dependent on the type of other parts in the same print job and their respective orientation on the build plate. Additionally the metal AM service provider has to take into account powder usage of a design, thermal stresses, etc.

Calculating the cost of a part is complicated and can be done faster and more accurate with the help of the right algorithms. On top of those direct costs are resources that are spent on talking and giving feedback to designers. Often they aren’t aware of all those factors that need to be taken into account to get to a successful print. The service providers spends a lot of time on iterating with the designer which results in a costly feedback loop and a higher internal cost.

What’s most interesting to me about this service, which would otherwise be of exclusive interest to service providers, is that Thrinno allows end users to try it out. For a small fee you can upload a 3D model and experiment with different configurations. In this way a user might be able to optimize their costs of engaging a 3D metal printing service later on.

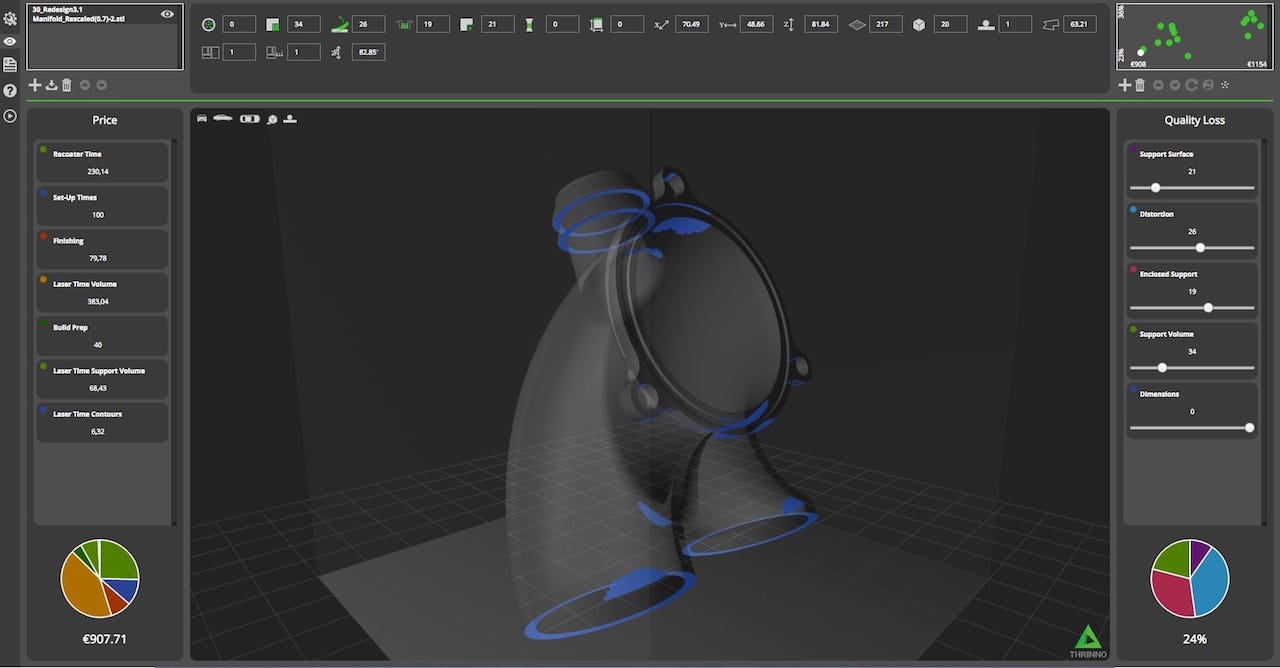

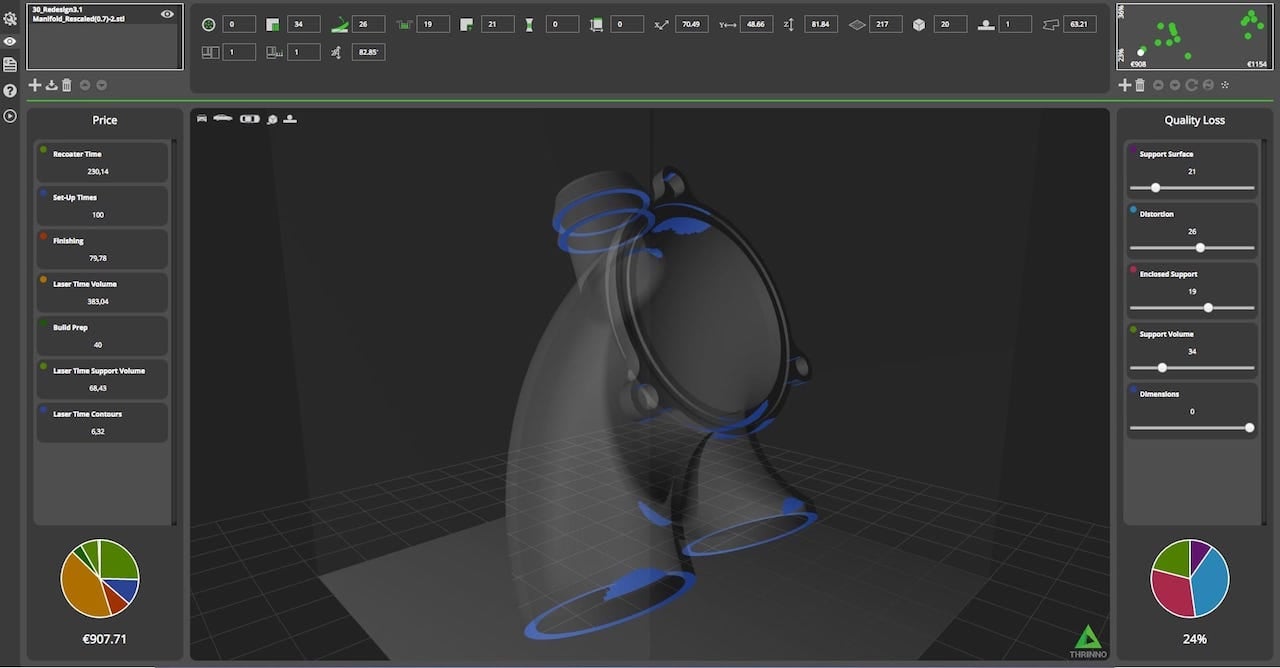

Here’s how their quoting process works:

- You make a profile of your printing specifications

- You import a model on which different algorithms are applied. These algorithms include amongst others the detection of amount of support, surfaces to be finished afterwards, thermal stresses, etc.

- Based on that and a chosen set of quality parameters, a price and quality score are calculated for different orientations, while taking into account the occupation rate on the build plate. A tool is provided to help you pick the optimal orientation.

- When the optimal orientation is chosen, a quotation is generated with visual feedback.

That, I believe, would be of great interest to anyone considering a 3D metal print.

Via Thrinno