We had the opportunity to tour Precision ADM, a new service specializing in 3D printed metal parts.

The Canada-based service provides metal printing to a variety of clients worldwide in automotive, medical and other industries, where the equipment and expertise in 3D metal printing is not present onsite.

And that last point is one of two things that are very apparent when visiting such a 3D printing plant:

One: 3D metal printing is a very difficult process.

and

Two: You need significant equipment and facilities to even attempt proper 3D metal printing.

But let’s take a look at Precision ADM’s set up first.

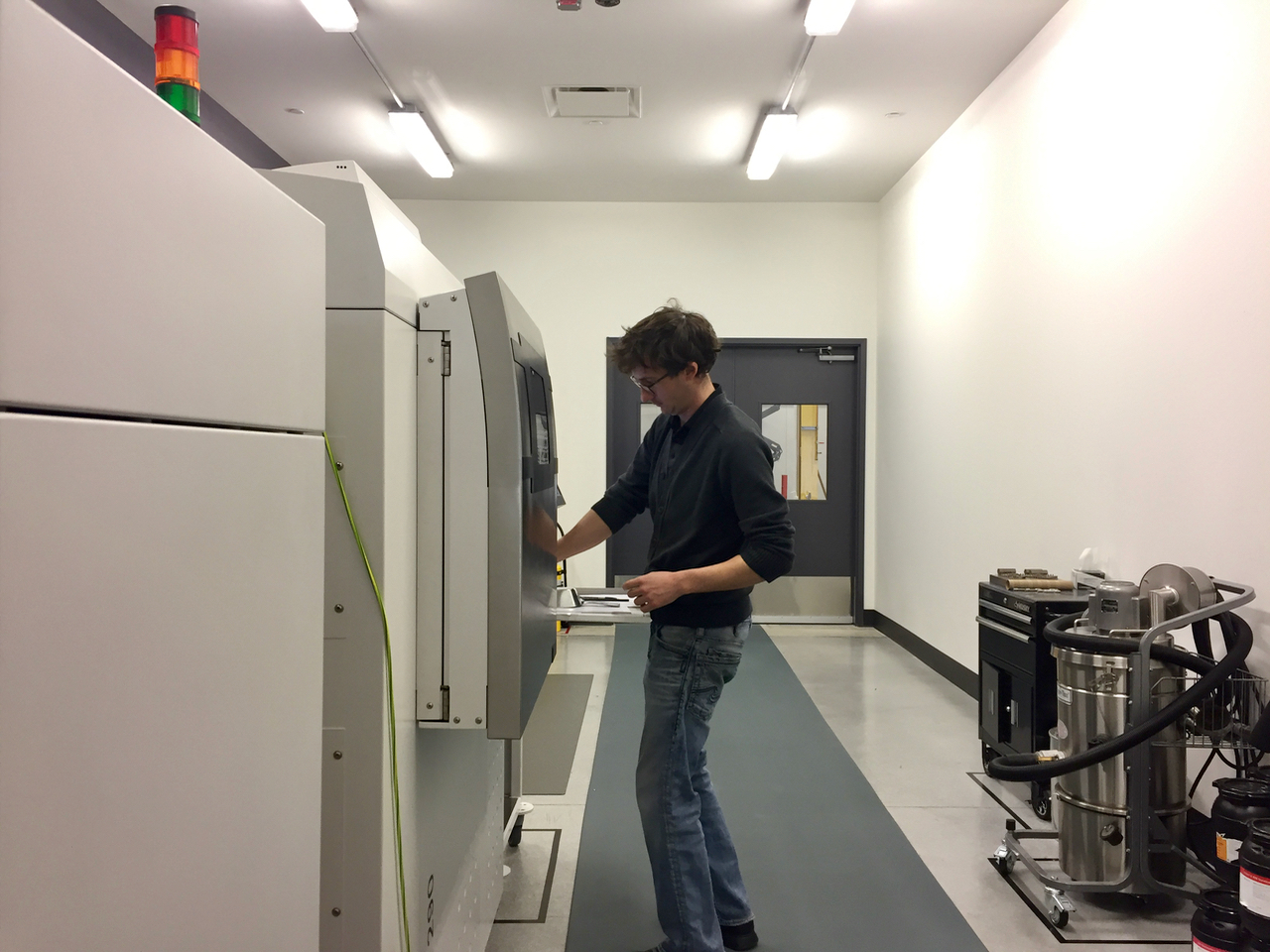

The company uses a pair of EOS 3D metal printers, each located in separate, environmentally controlled operation rooms. The environmental control is necessary to account for the possibility of material powder escaping, which could be toxic or even explosive if exposed to the oxygen in our atmosphere.

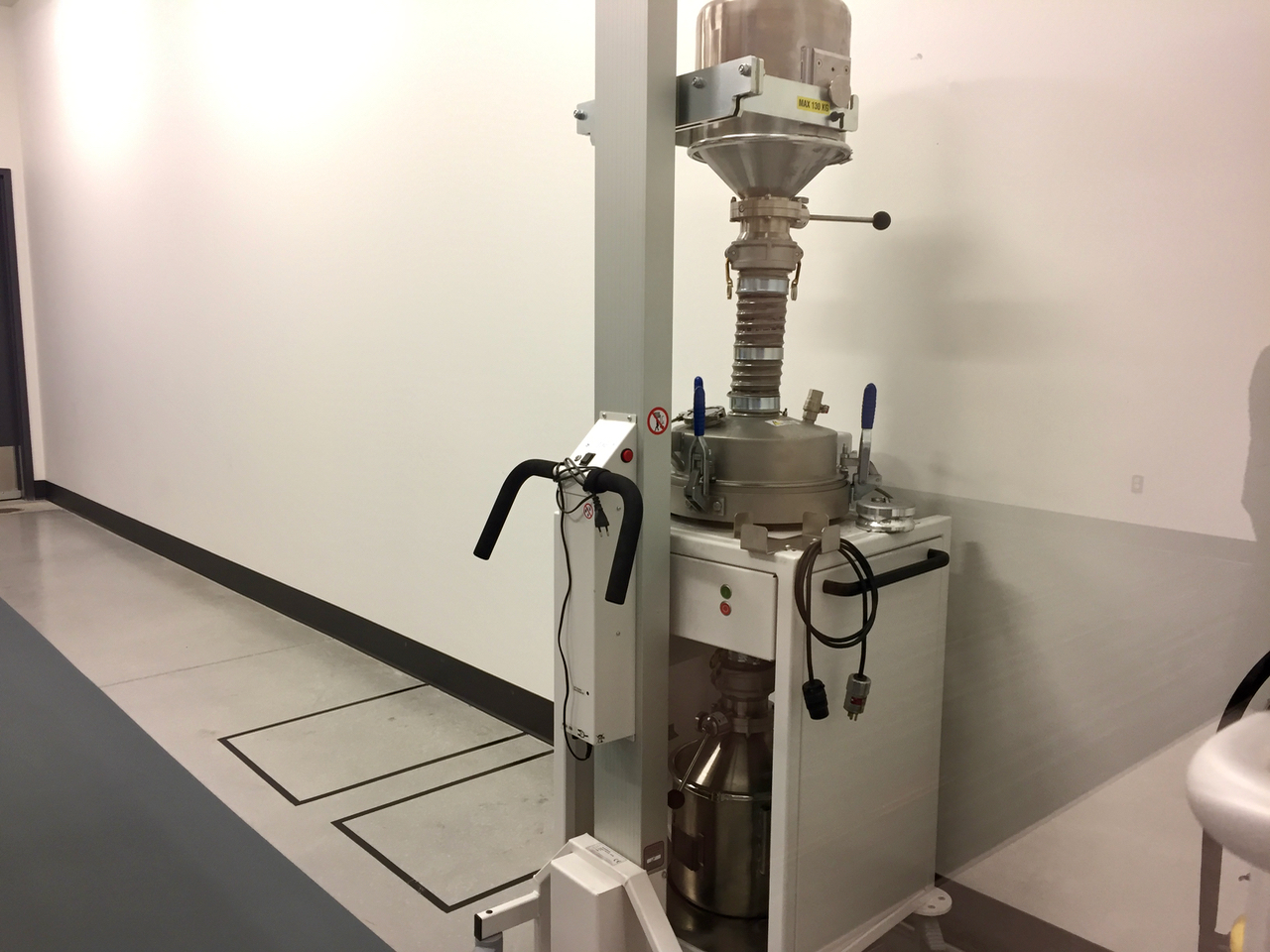

As seen here, the environmental rooms contain a transfer unit to handle the potentially dangerous powder. It’s captured from the completed prints and run through this sieving unit, which eliminates any fused bits that have separated from the main body of the print. This enables re-use of the very expensive powder, which can run up to USD$500 per kg.

Precision ADM operates two separate environmental rooms for their 3D metal printers. Why not just put both machines in one room and save the construction cost? The answer is interesting.

It turns out that approximately five percent of the population is allergic to nickel. Thus, you cannot contaminate any prints destined for medical implantation (a common item printed by Precision ADM). So, if Precision ADM wants to print anything in nickel powder, they must do so in one of the printer rooms that’s designated for “nickel”, and the other room is “nickel-free”.

Unlike many plastic 3D printers, 3D metal printers are used primarily for production parts, such as medical implants or engine components. And that production capability suddenly demands a great deal more scrutiny of the part quality. Precision ADM has to individually engineer each print job with the correct parameters to ensure the part printed has the correct engineering characteristics. This means they must strive to achieve the best microscopic crystalline structure formed during the 3D printing process.

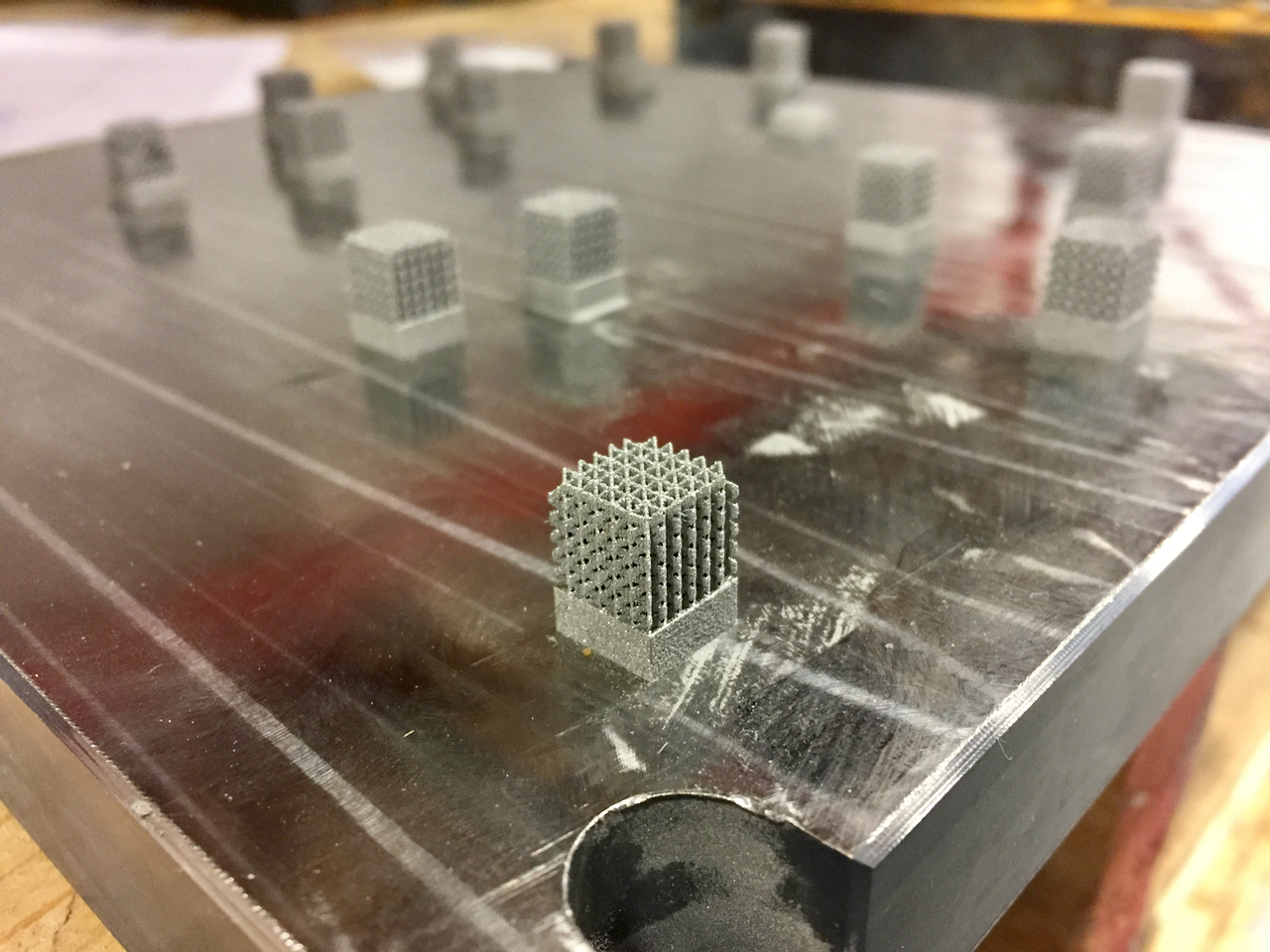

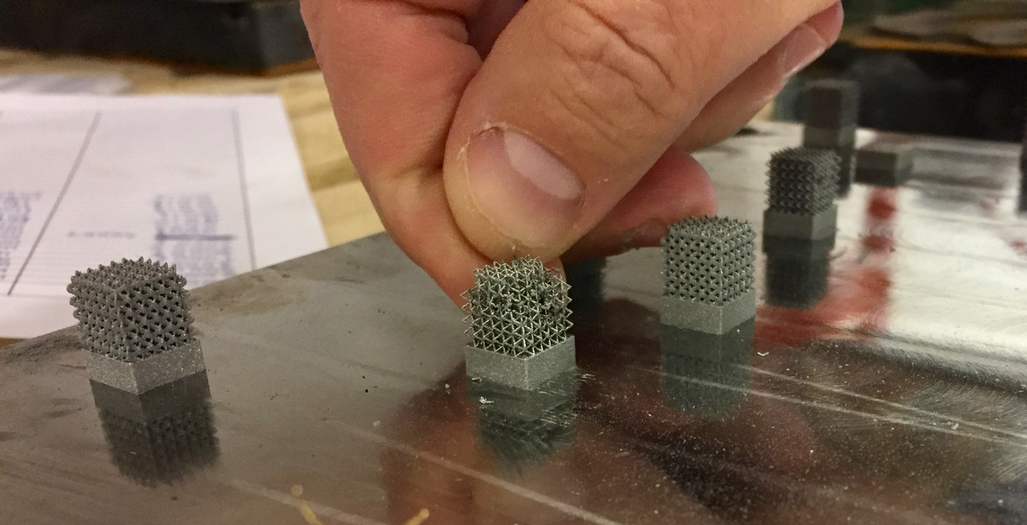

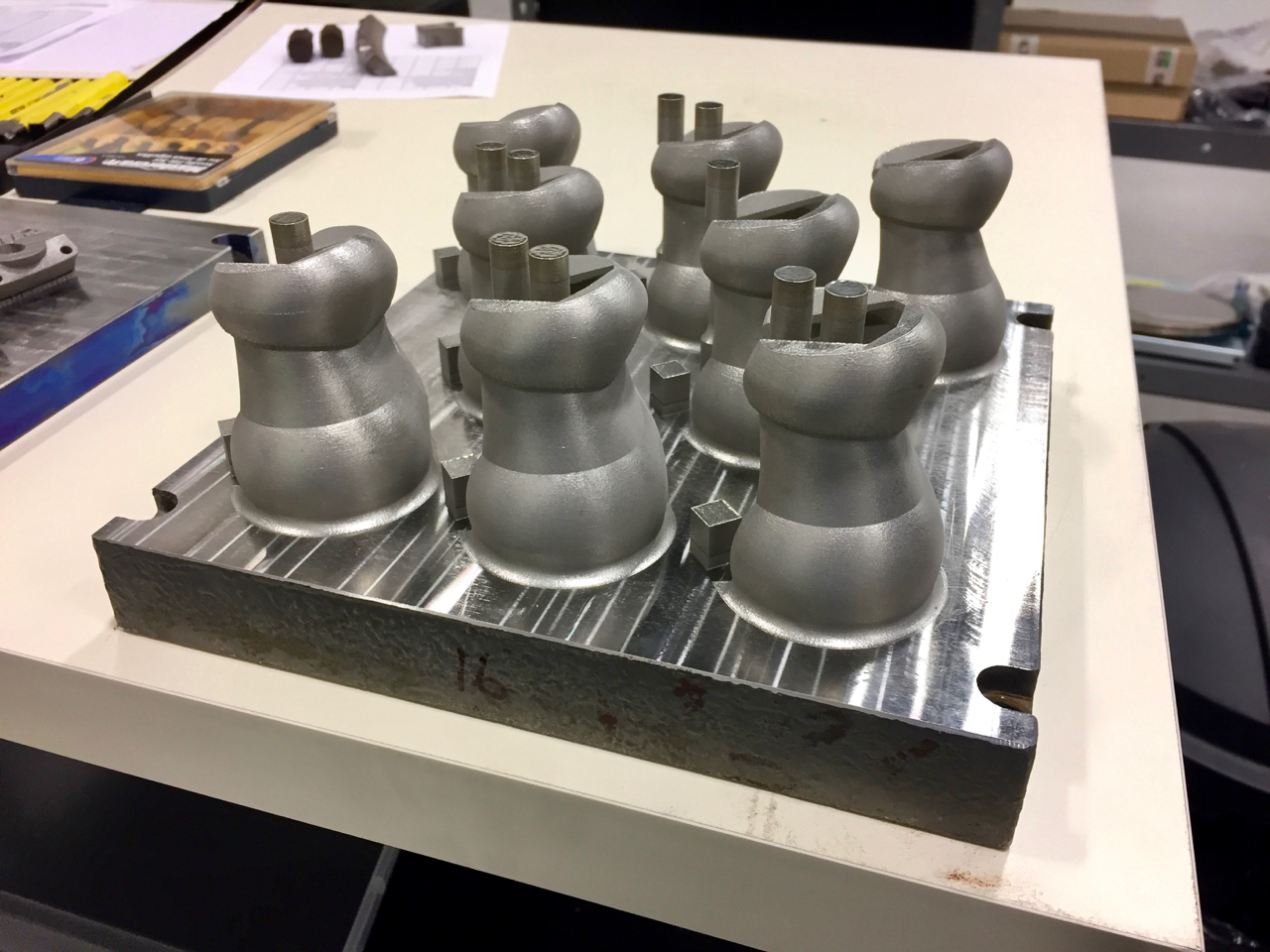

Here you can see some test prints where the company had been testing a variety of different parameter configurations. What they’re actually doing is varying the power and speed of the laser, combined with the chamber temperatures over time. It’s kind of like searching for the optimum combination of parameters.

To test the results, the printed parts are examined – and sometimes crushed to gauge their strength.

But there’s another problem facing 3D metal printing operations; repeatability. Even if you eventually arrive at the correct characteristics, your production line has to be able to produce EXACTLY the same part, with the same equipment, same materials, literally forever. A variation is effectively a different part that would have to go through challenging certification processes.

Regarding extra equipment required, there is much to be said.

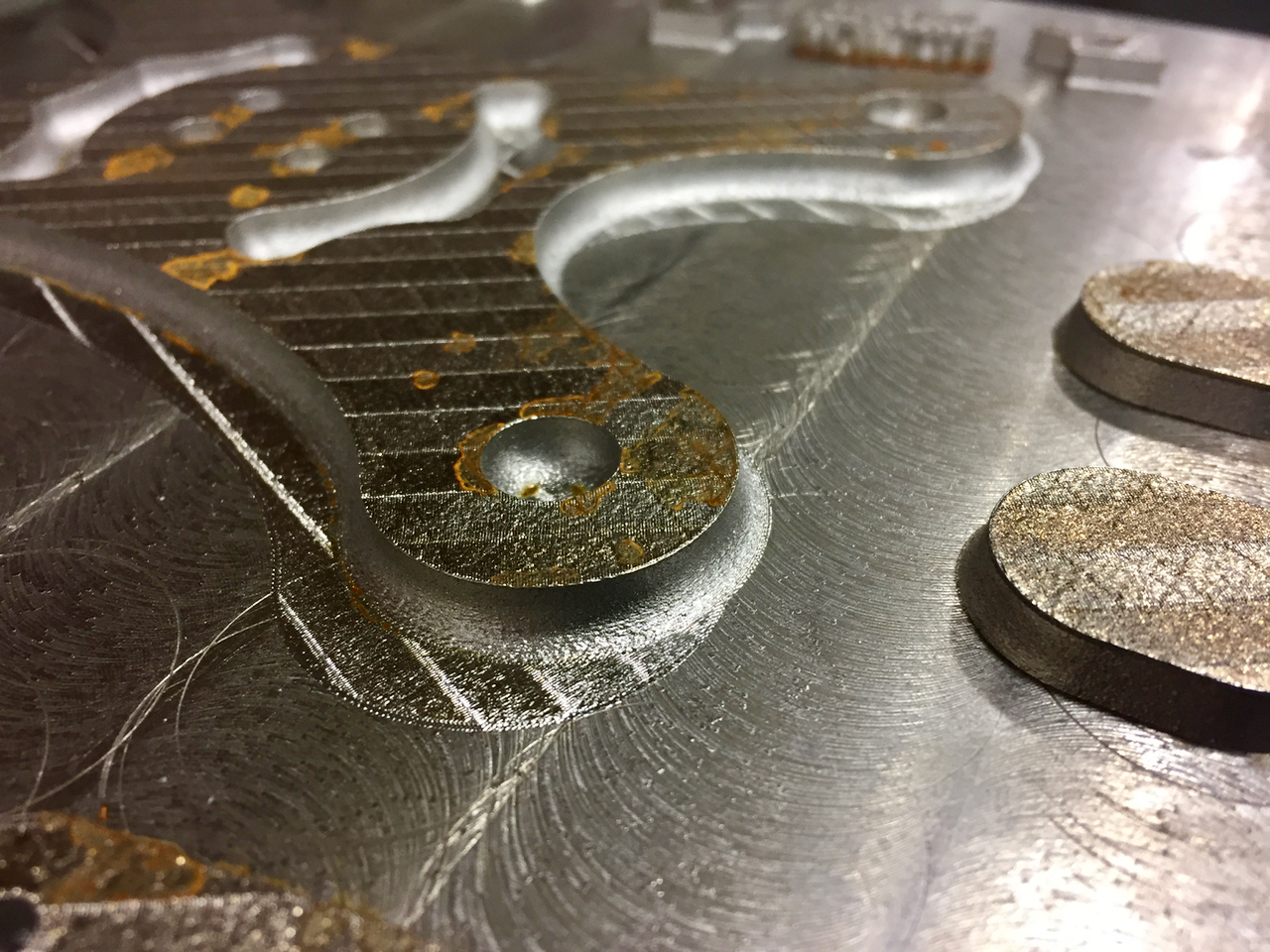

3D metal printers typically produce their results on a thick metal plate, as shown here.

The parts are removed by using an expensive device known as a wire EDM, which can very precisely cut a plane across the plate to separate the parts. So you must have one of them too.

Yes, you end up with a bunch of used plates, but they are recyclable: simply run them through the wire EDM again and they become a clean, flat surface for the next job.

Once the part is removed, it may require finishing. This means you must have CNC mills ready to accept the part and polish its surface, for example. At Precision ADM they have several such machines, as shown here. They are large, expensive and extremely heavy. One of them actually required the operation to take apart the floor and pour in one meter of concrete to provide sufficient strength to hold up the machine.

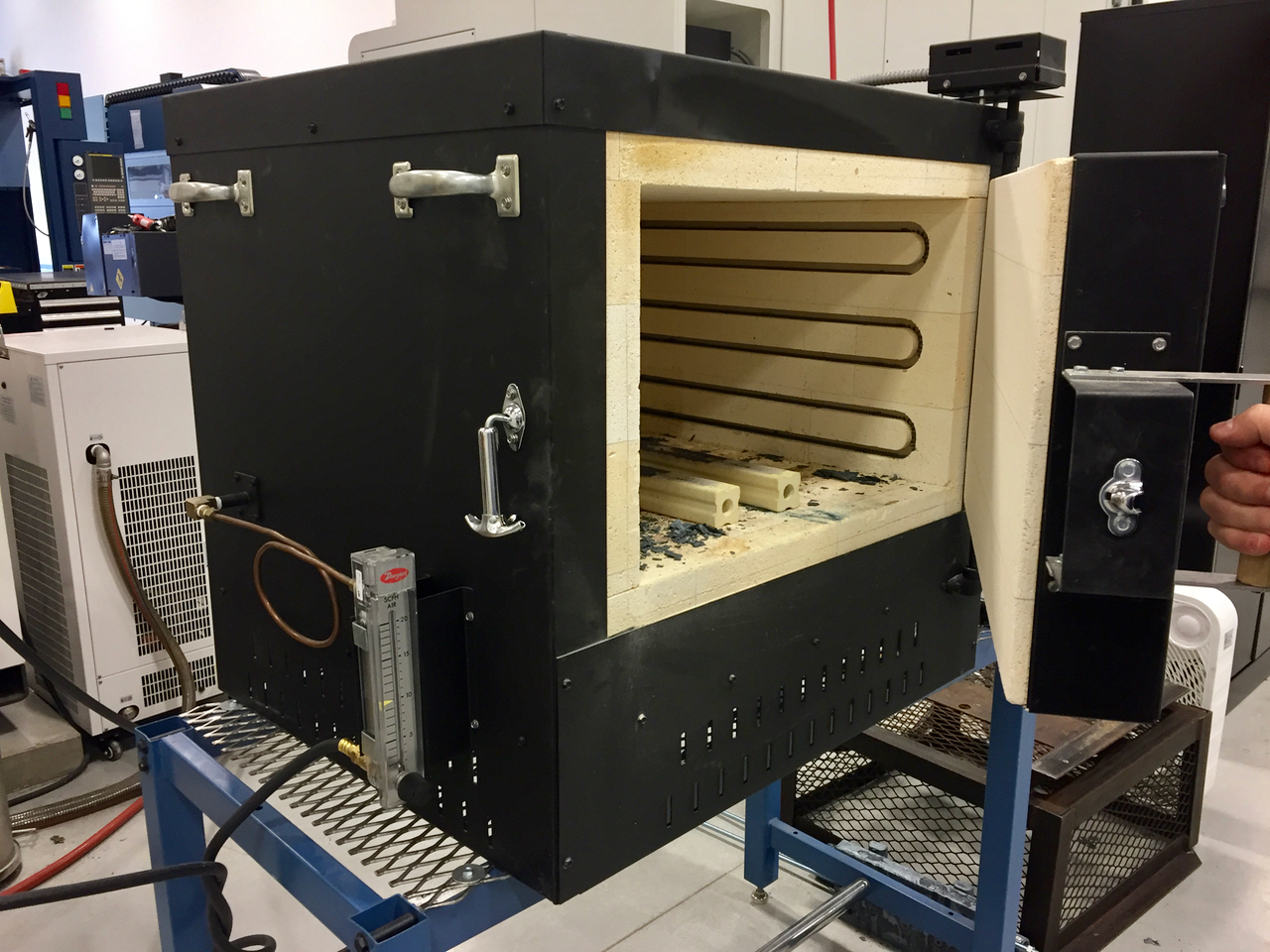

3D metal printing is very challenging in terms of temperature management. For example, a complex piece with lots of support material may warp during printing because the heat flows through the support structure were not optimized properly.

Precision ADM explained that some prints actually warp these thick plates, and that to cut them with the wire EDM they must re-heat them in this furnace to take out the warp. This is a highly complex problem and the company has been using dedicated software to simulate solutions for specific projects.

All of this requires a team of very skilled technicians that can design the processes, tune the machines and operate everything flawlessly. That’s something few companies can say they have, and is a major reason why you might consider outsourcing your 3D metal printing to a service like Precision ADM.

And you have to do this all at a cost that makes sense for the client. It’s an extremely challenging business to be in.

I spoke with CEO Martin Petrak, who explained the huge challenges and opportunities for such a business.

The opportunity is to produce highly complex – and customized to the individual – metal components for use in medical applications at a far lower cost. But, Petrak explained, there is a significant certification process to undergo. One big challenge they had was how to certify that the part contains no loose particles. It’s something the company had to design a specific process to solve.

Petrak explained they’ve developed a complex ten-step process for developing solutions to take them through a project with a client. The expertise they’ve gained through experience is considerable and would be missing from any first-time 3D metal printing operation.

However, once done, they can use their certified process to produce as many as required. In other words, there’s a huge hill to climb at first.

I expect companies like Precision ADM to gradually grow their capability to enable them to take on extremely complex 3D metal printing projects in the future.

Via Precision ADM