VSHAPER has demonstrated a new 3D printer that could point towards a tilted future of 3D printing.

The Polish company produces a line of professional desktop 3D printers, including some capable of handling very high temperature materials. While we had a close look at these machines at FormNext, the one that caught our eye most was a demonstration machine.

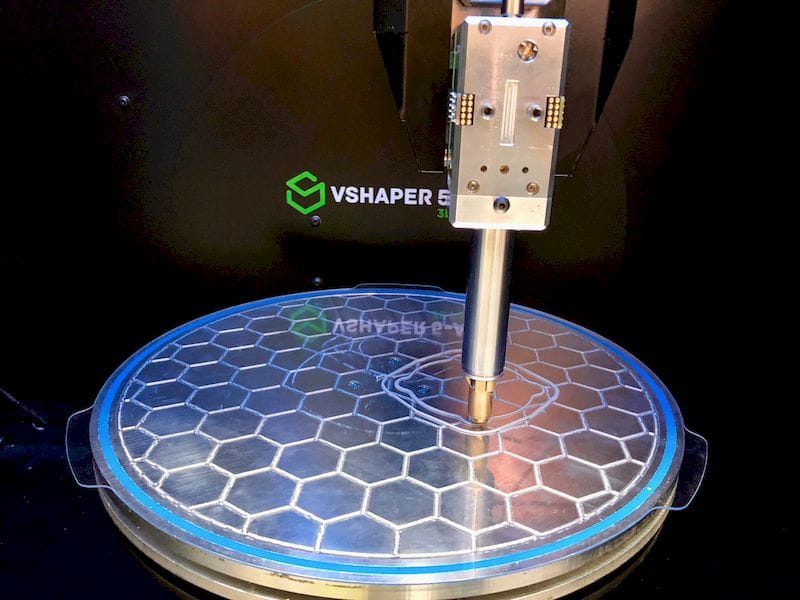

Rather than using the more frequently encountered cartesian or delta-style motion systems, the unnamed prototype 3D printer uses a 5-axis robot mechanism. In this concept, a robot arm moves the extruder around its 300mm diameter x 300mm tall build chamber to deposit material from a more or less conventional hot end.

However, there’s a twist. Or rather a tilt.

In this prototype the build plate can tip at different angles during printing operations. By coordinating movements with the robot arm, the system is easily able to 3D print objects without the need for support structures!

How does it accomplish this? By simply tilting the object in mid-print to compensate for the overhang.

Filament extrusion systems typically have some tolerance for overhangs of about 45 degrees or even more in some cases. Thus by tipping the print this can be completely overcome.

And indeed it works. Here we see an example print from the prototype device, where you can clearly see the layer lines. Note that they are NOT parallel to the base, something we’d see on virtually all other 3D prints of this object.

There’s another interesting advantage here, in that the strength of the object can be adjusted somewhat through this process. It’s well known that the weakest point of a filament extrusion 3D print is the layer adhesion; if a print is going to break, it will be on the layer lines.

With this process it should be possible to make more choices about the orientation of the layer lines, making a part stronger where it needs to be. In a typical 3D printer you get only one choice of how to orient all the layer lines in the entire part.

Of course, such choices might compromise the ability to 3D print without support structures, but then you’d simply add some structures where needed and trim them off afterwards.

Another interesting feature is the heated chamber. The source of the heat is the build plate, as you might expect, but there’s a difference. The heated plate is divided into 18 unique zones that can be independently controlled. This can save energy and also speed up printing as less time would be required to heat smaller sections of the plate.

There’s more. This device is intended to act as a multi-tool manufacturing device. The idea is to use a tool changer to swap out the 3D print extruder and replace it automatically with, say, a milling head.

The software required to manage this system is no doubt complex, due to the requirement to incorporate the 5-axis movements as well as the tool changing aspect. However, VSHAPER’s “SoftShaper” software is intended to do this.

We’re told the price of this machine will be in the €300,000 (USD$356,000) range and it could emerge in 2019, so it’s quite a ways off.

Via VSHAPER