Monica Sokolowski studied medical imaging, managed dental imaging centers and thought out-loud about the challenges of finding eyeglasses that fit each unique face perfectly.

Her current project in Custom 3D printed eyewear was born from her background in dental surgical guides and a desire to wear glasses that fit. She lives and works in Toronto, Canada.

Nora Toure: Monica, could you let us know about your background and what brought you into 3D printing in the first place?

Monica Sokolowski: I’m a medical radiation technologist, so I initially worked in a hospital setting acquiring images of patients through MRI and nuclear medicine. My husband (an oral radiologist) opened Canaray (an oral radiology practice) in November 2010 and once it started growing, I took over the management of the imaging at all of the locations. We realized that dentistry was transitioning from analog to digital, and decided to start producing CAD/CAM surgical guides in January 2012, based on 3D surface scans of dental models and 3D cone beam CT data.

Eventually, we procured our first 3D printer, in order to eliminate several lab steps. At the time we were one of the first small companies to make the leap to 3D printed surgical guides to directly distribute to our customers. We lost money on probably every guide we made for the first 3 years, but the desire to keep learning and improving kept us going, I think…It was more about building a foundation for the future than a short term moneymaking gambit.

The field was young, our customers were forgiving, and we spent a lot of time fiddling with techniques and parameters (because online information was sparse at the time) until we established a workflow that consistently produced good results. From there, we slowly increased the numbers and types of printers in our lab.

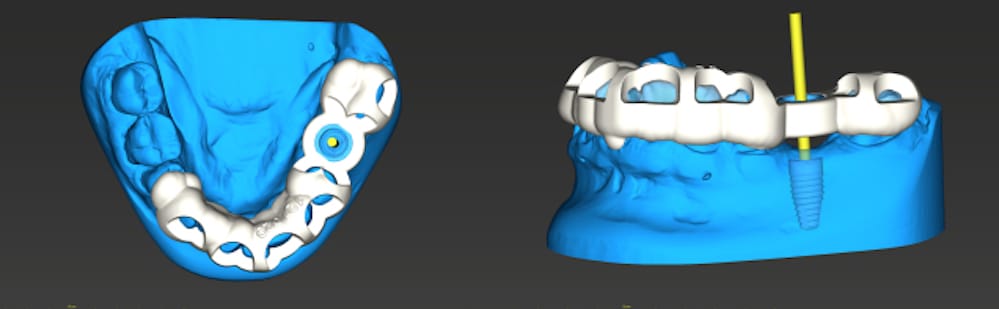

An example of CAD models of a dental surgical guide (shown in white) on a surface scan of a dental arch (shown in blue). Both items would be 3D printed, but in different materials with properties pertinent to their function.

Read more at Women in 3D Printing