An intriguing new professional desktop 3D printer appeared on Indiegogo, and their approach seems quite unique.

The Ark is billed as the “first 3D printer for architects”, which at first I found a bit strange, as 3D printers have been used for decades by architects. There has long been use of 3D printers by architects to produce realistic 3D models of proposed structures, and this led to relatively common use of the sole color 3D printing process of the day, from the former ZCorp. In fact, one of our very first posts talked about this almost ten years ago.

So what makes the Ark the “first 3D printer for architects”? Technically, it’s a bit hard to tell by looking at the machine’s specifications.

This is a plastic extrusion machine that prints only in PLA-type materials, making it largely unsuitable as a machine for engineers hoping to use more exotic materials like ULTEM. Other PLA-only machines are far lower priced and targeted at consumers, educational markets and DIY folks, each of which is unlikely to purchase the far more expensive Ark.

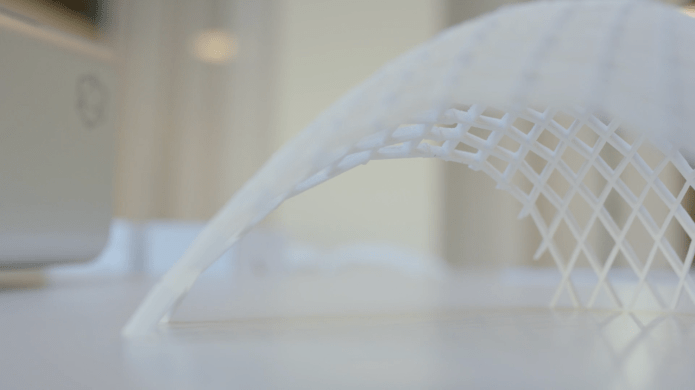

Currently Platonic offers only several “architecture friendly” PLA materials, including: Matte White, Wood, Crystal Clear, Terracotta, Clay, Granite and Concrete.

The pre-assembled Ark boasts a 0.05mm layer size, which is very good, surpassing the defacto standard of 0.10mm layers on most competing machines. Its build volume is a modest 200 x 200 x 200mm, and print speeds are typical, up to 100mm/second using its Bowden-style system.

The machine includes an auto-leveling system to ensure reliable printing, but is an open format machine lacking an enclosure for heat control.

It’s connected via network for easy access, and is equipped with a swappable nozzle system with two sizes of nozzle.

I know what you’re thinking. This is a pretty typical desktop 3D printer, with almost no notable technological features. Machines with these specifications are easily found from many sources at pricing far less than the Ark’s listed prices. There are even more machines of this type littering the failure zone of crowdfunding, where incompetent management blew up the company before they could even ship their machines.

Then, you ask, what could possibly be the attraction to this machine?

It’s not the machine; it’s how it is used.

Platonics has taken an extremely different approach to the design of this machine that should be a model for other 3D printer manufacturers.

It’s almost as if the “3D printer” part of their system was incidental, because the bulk of their value proposition is in how the machine is operated. Here’s what they did:

They targeted a very specific market, Professional Architects. They spent considerable time talking with actual architects around the world to understand how they work with 3D printers.

They documented the workflow required of architects when using existing 3D printers, and in that workflow identified the points of inefficiency that could be attacked.

These points of inefficiency were specifically addressed in the design of the Platonics Ark system:

CAD to Print: The Ark system’s software is able to directly interface with the most common 3D CAD systems used for architectural design, including Archicad, Revit, Rhino, Vectorworks and Sketchup. Thus there is no need for “export to STL” and “import STL”. Of greater importance, perhaps, is that they’ve managed to integrate a sophisticated STL repair facility into the workflow, so that models are automatically fixed before being printed. The bottom line here is that an architect in a CAD tool can simply “print” and be done with the job.

Fully Automated: Yes, this machine includes auto-leveling, but there are a number of additional automation features. The system automatically performs its own maintenance, such as cleaning nozzles and extruders. I’m not sure exactly how they do this, but it sounds like a reasonable idea. Of course, the machine is completely set up and ready to go when you receive it.

Support system: A special “premium support” package offers some very interesting features, including a dedicated account manager to help with any support issues; a recycling program for unused prints; and perhaps the most interesting feature, “automatic restocking”. In this feature, the machine detects when it is printing each type of material (evidently the spools must include some type of RFID chip that is read by the machine). The system then gauges when you should be running low on supplies and automatically orders more spools from Platonic! While the Ark is an “open materials” machine, this might be a reason to use only Platonic materials.

Pricing of the machine is, as always, in several different aspects. The basic Ark is available at a 40% discount at €2,095 (USD$2,460), with a regular price of €3,495 (USD$4,110). This unit is not integrated with the 3D architectural CAD systems.

For one that is integrated, you must step up to the €2,575 (USD$3,030) version, also 40% discounted during launch.

If you’d like an Ark with the Premium Support feature, you must pay €2,995 (USD$3,520).

All machines are to be delivered in May 2018, so there is a bit of a wait.

I have to say that as startups go, this one appears quite competent. They have a large team, have developed the machine and systems – and have been running them at pilot sites successfully. This is unlike many other crowdfunding launches were there is barely even a CAD image of the imaginary machine.

The company has also partnered with a reputable german manufacturing firm to produce the machines, and that alone tells me they’ve spent some time engineering the design for manufacturing. It seems quite promising.

But the moral of the story here is that struggling 3D printer companies should do exactly what Platonics has done: picked a very specific market and SOLVE THEIR PROBLEMS. It makes little sense to build a generic machine and hope someone might buy it, especially given the massive amount of choice available today.