When reviewing the specs for 3D printers, you might encounter the term “CoreXY”. What is a “CoreXY” system?

The term refers to a particular design for the X and Y motion systems on not only 3D printers but also other types of CNC machines.

The motion system is a critical component of 3D printers, particularly filament-based cartesian designs where the hot end must be moved rapidly in three dimensions. While the Z-axis is a separate matter, the X and Y axis motion systems can be more complex and there are multiple methods of doing so.

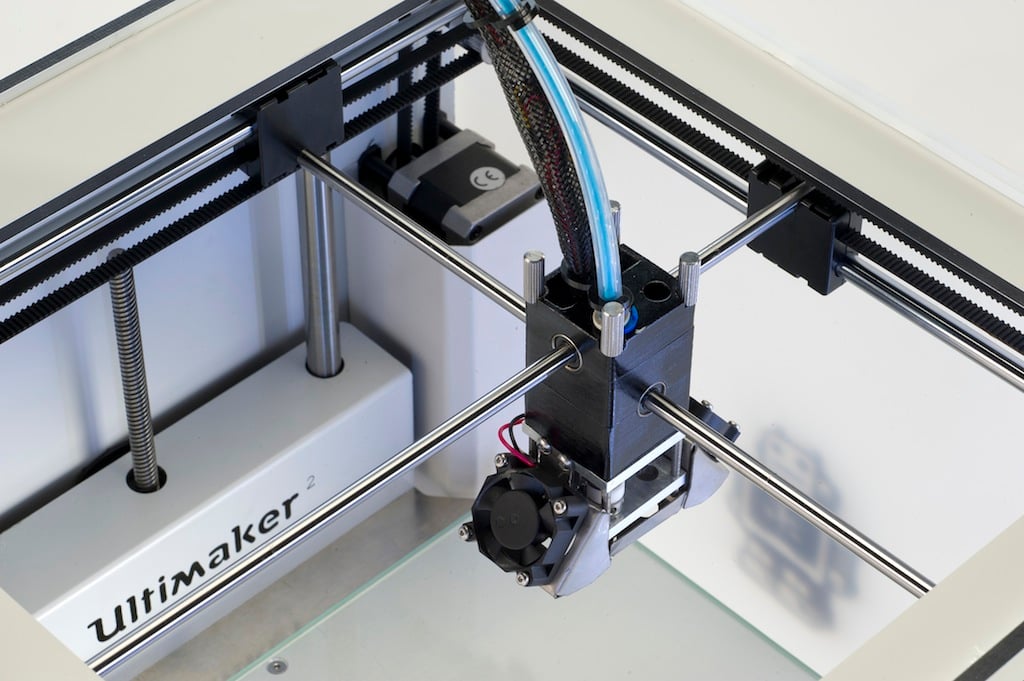

Here’s a design used by Ultimaker on their machines. Other manufacturers use a variety of other schemes.

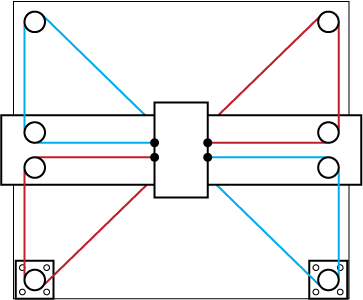

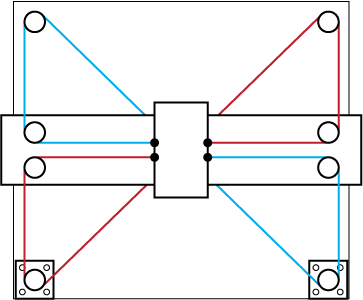

But one design that’s becoming more popular is the CoreXY system, as described in the excellent CoreXY site made by Ilan Moyer. Here’s how it works:

As you can see, the system requires only two stepper motors and provides a means of moving both axes independently or simultaneously. The major benefit of the design is that the motors remain in a static position.

This is different from some other designs in which one of the motors must be moved along the axis. The weight of the motor makes it more difficult to change directions as inertia prevails.

Therefore, it is theoretically possible for a CoreXY-based system to operate faster than some other designs.

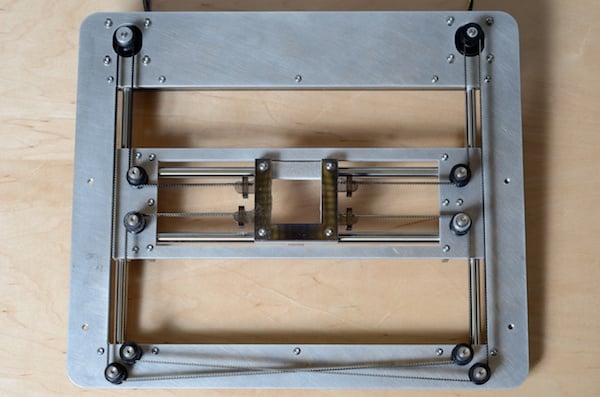

The CoreXY design is merely a concept and not an implementation. It’s left to machine designers to develop specific plans to implement their own CoreXY system. Here is a typical implementation made from waterjet-cut aluminum plate:

But what does this all mean? It’s a specification you can look for when examining a 3D printer, and it might – or might not – mean the printer could be somewhat faster when printing than other models. Or it might not, as print speed is a statistic determined not only by the motion system, but by a number of other system components.

Via CoreXY