Swiss students have invented a new twist on 3D printing without support material.

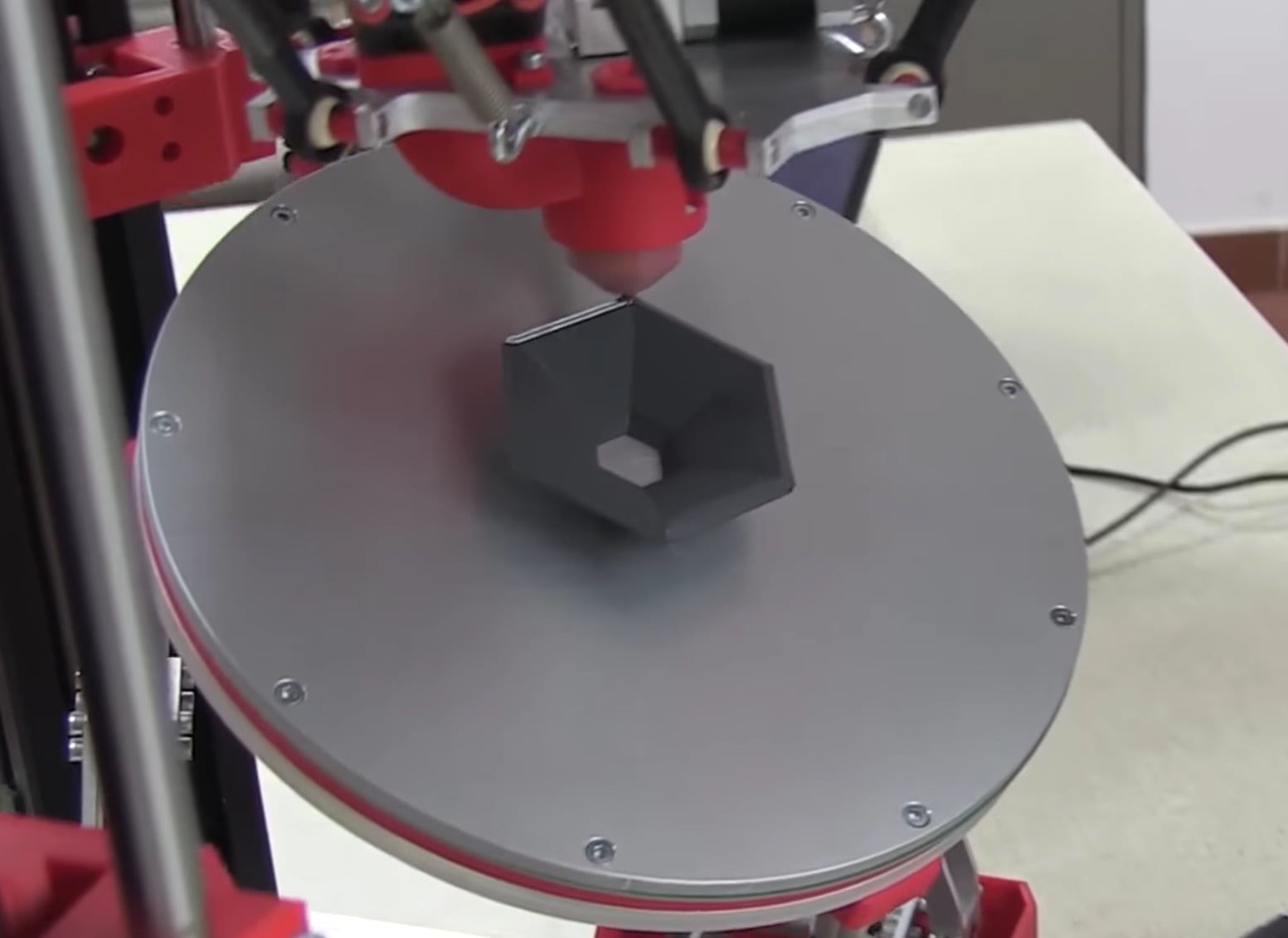

Their idea is to tilt the print bed as the object is being 3D printed. This effectively changes the angle of deposition on previous material and if coordinated properly, can essentially eliminate overhang angles entirely.

This is accomplished by mobilizing the print bed. As you can see in the video, the print surface is tilted in arbitrary directions through a type of delta-style apparatus mounted underneath the bed.

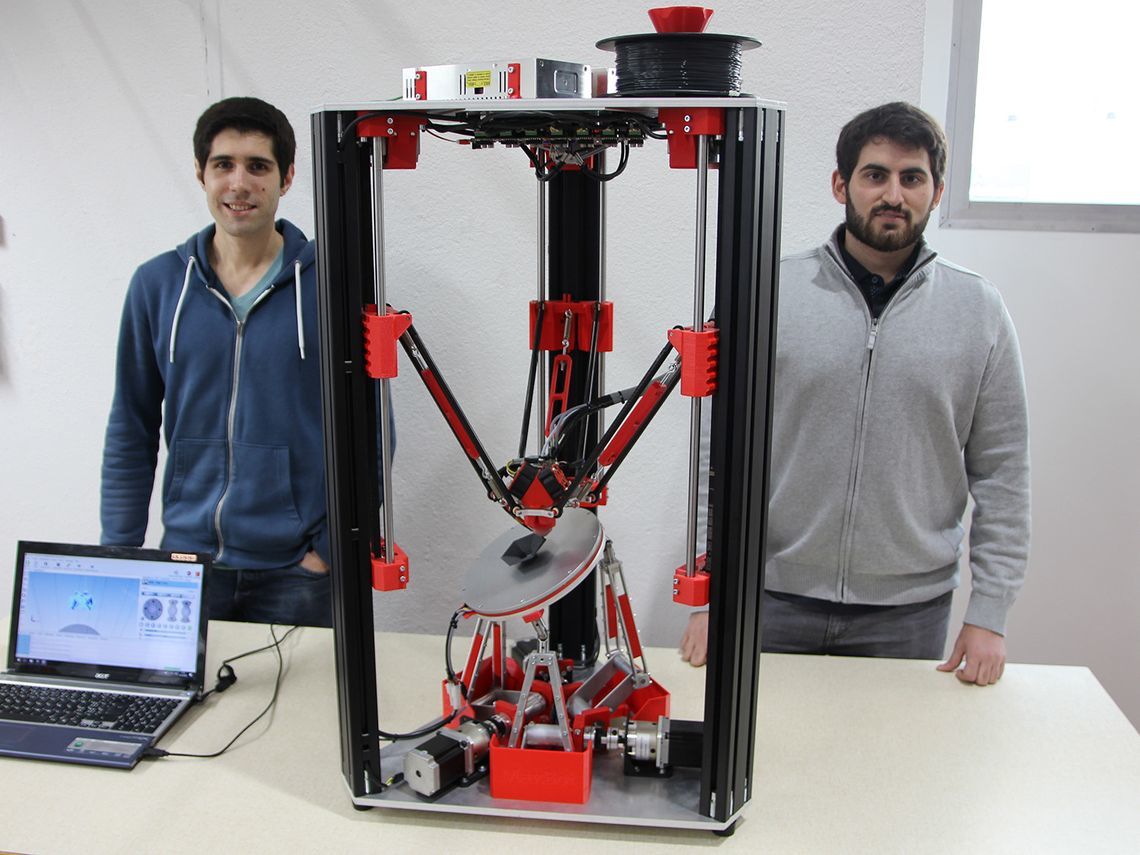

To make this work, the students from the Zurich University of Applied Sciences, Oliver Tolar and Denis Herrmann, had to compose software that would coordinate motions between the tilting print surface and the moving delta extruder, something you might not find in a typical 3D print slicing engine.

The result of this capability is the idea that you could 3D potentially 3D print an object without the need for support material: just tilt the bed appropriately at the moment of extrusion to remove the overhang.

This concept is startlingly reminiscent of Stratasys’ new Robotic Demonstrator, a multi-axis 3D printer based on a robot arm. Like the Swiss machine, the Robotic Demonstrator simply uses its axes to tilt the print to remove overhangs.

However, this approach would be vastly less expensive than Stratasys’ concept and could possibly become a standard style feature on many desktop 3D printers.

Can this actually eliminate support structures? In many cases, I think it could, but there are certainly pathological geometric shapes that might not be applicable, or those whose design might exceed the tilting capability of the bed.

But for most cases of simple objects, this capability would be hugely welcomed and used every day.

I’m hoping this concept makes its way into products as soon as possible.

Via Heise (German) and Hackaday