It seems there are an increasing number of 3D metal printer options recently, and there’s one more from CoLiDo.

Print-Rite, the company behind the CoLiDo brand of 3D printers, is a 35 year old aftermarket 2D printer consumable company, who began developing simple desktop 3D printers a few years ago. Today they boast a rather extensive product line, including a huge delta-style unit.

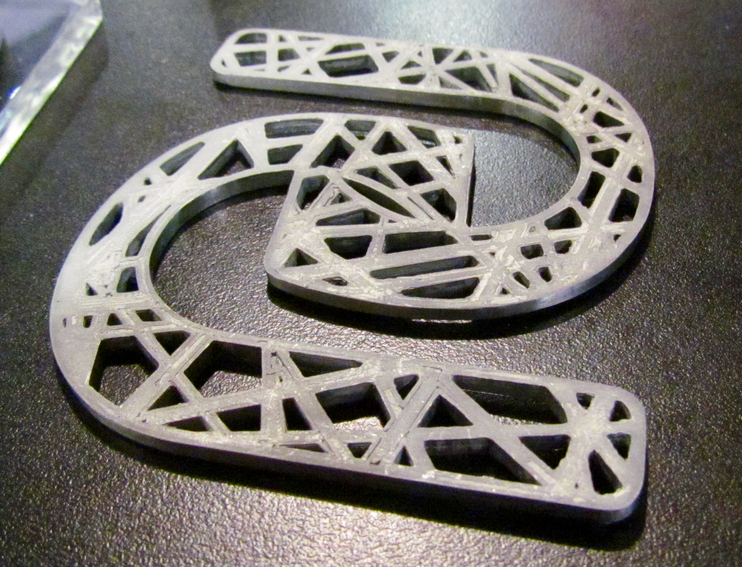

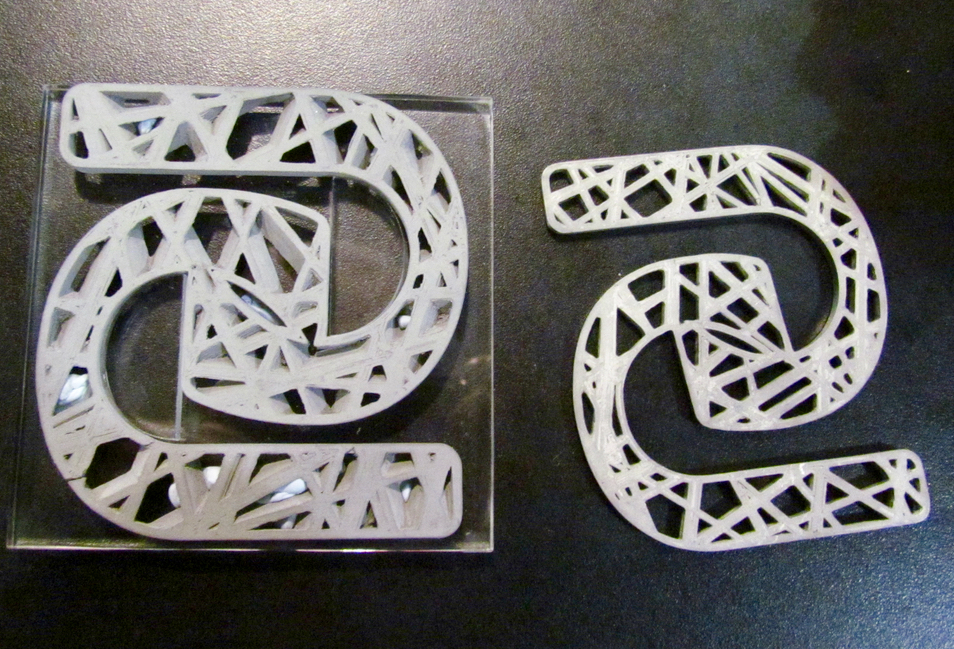

The CoLiDo product line has thus far focused on polymers, with a number of filament-powered machines. But at CES in Las Vegas last week the company showed evidence – hard metallic evidence – that they’ve been working on a secret 3D metal printer.

The new machine was not shown, but samples were shown, as seen here and at top.

Their process is one that is becoming familiar among low-cost 3D metal printing options: post-sintering. Here’s how the CoLiDo process works:

- They’ve developed a special filament that contains around 90% metal particles

- This filament is printed on a specially designed desktop 3D printer in the usual manner

- The “green” part that’s produced is removed from the printer and fired in a furnace

- Firing can take, in the example of stainless steel, 24 hours at 1600C to complete

- The non-metallic portions of the print are burned out at these temperatures

- The metallic particles fuse together to form a dense, solid metallic object

- The completed part shrinks approximately 19% from its green state

Obviously, this process will be spectacularly less expensive than conventional powder-energy systems. The quality and consistency of the 3D printed metal parts, however, is unknown and will require considerable testing.

Nevertheless, this process could enable metal printing at much lower prices, making the capability available to many more people and companies, should their application fit within the quality envelope of CoLiDo’s printed parts.

Is there a price for this amazing machine? None yet, apparently. But we will find out in July, when this machine begins beta testing with clients.

Via CoLiDo