Researchers at Trinity College in Dublin have worked out a new process for 3D printing live, complex bone structures.

BioPrinting is a very tricky business. Unlike conventional 3D printing in which a single material is deposited in layers to form a complete 3D object, biological material has a peculiar requirement: it must be ALIVE.

In order to meet that ultimate requirement, you can’t just print “cells” and hope it works. Life is a machine made of many interacting components. The cells must be supplied with nutrients that must travel within conduits, solid structures must hold up the entire apparatus.

That’s hard to 3D print.

Some success has been achieved by depositing living cells on a “scaffold” structure and let them “grow” by themselves into the desired object, whereupon the scaffold dissolves.

But up until now there hasn’t been a good way to 3D print bone structures.

Researchers at the AMBER materials science centre in Trinity College have discovered a way to do this.

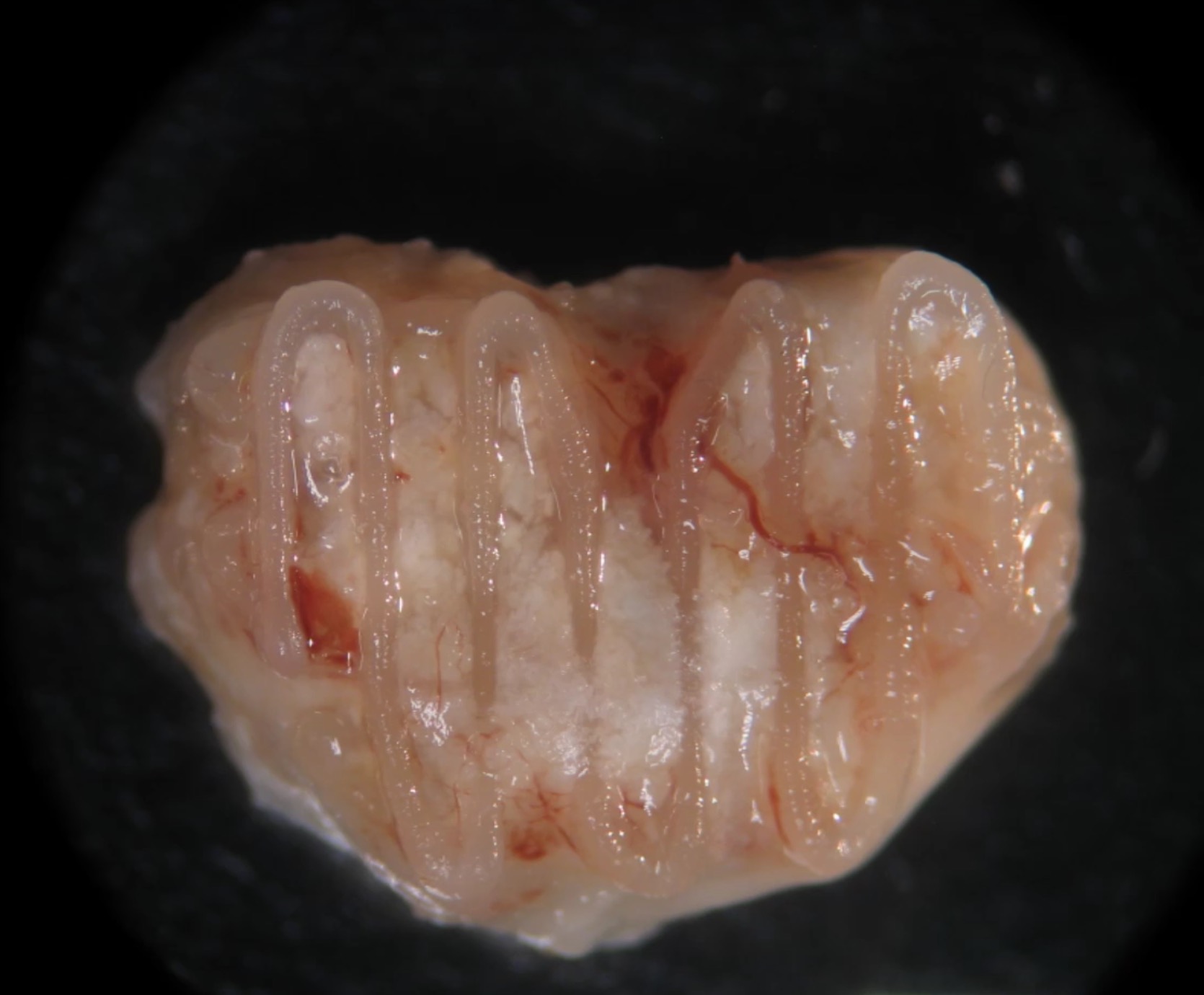

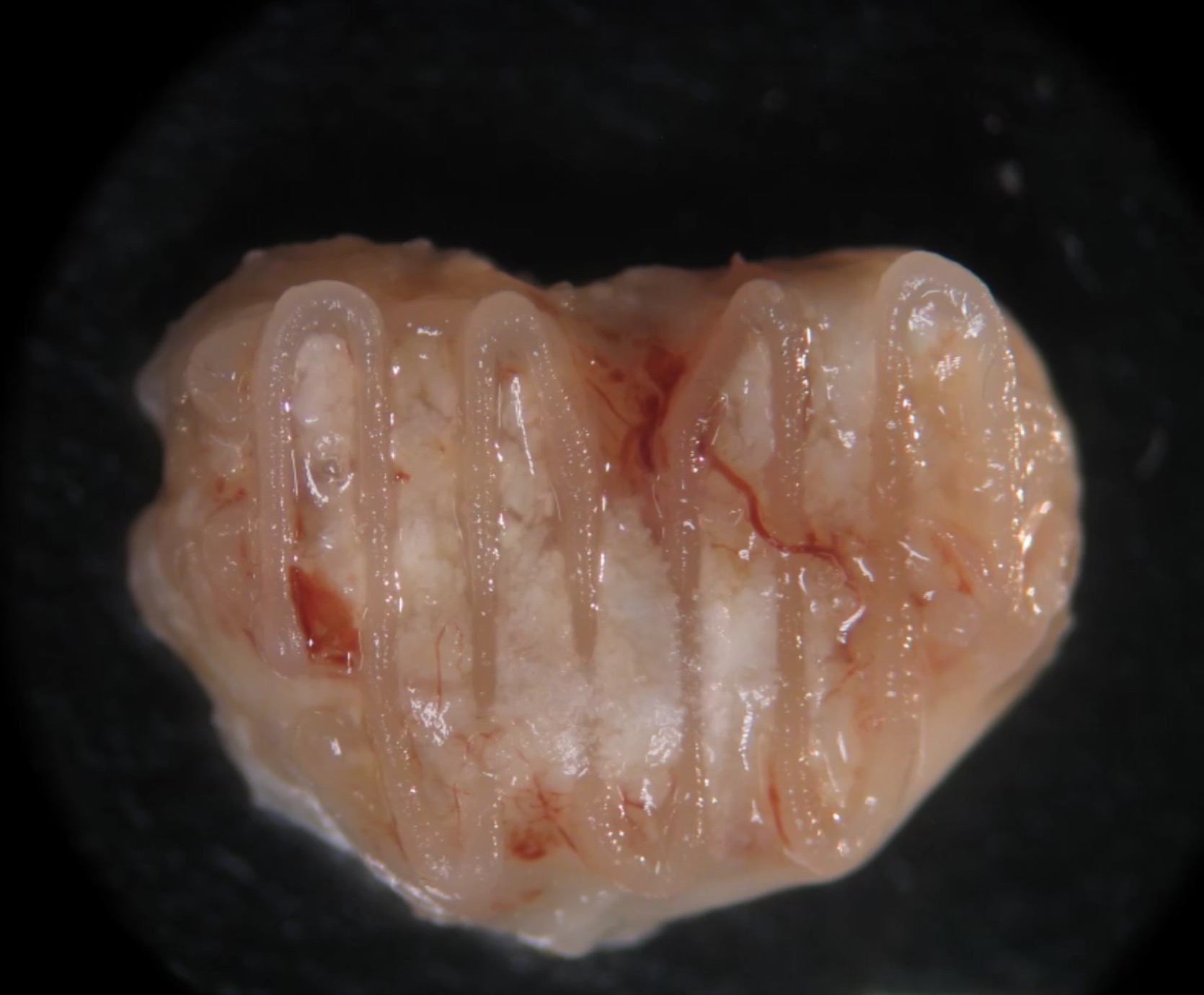

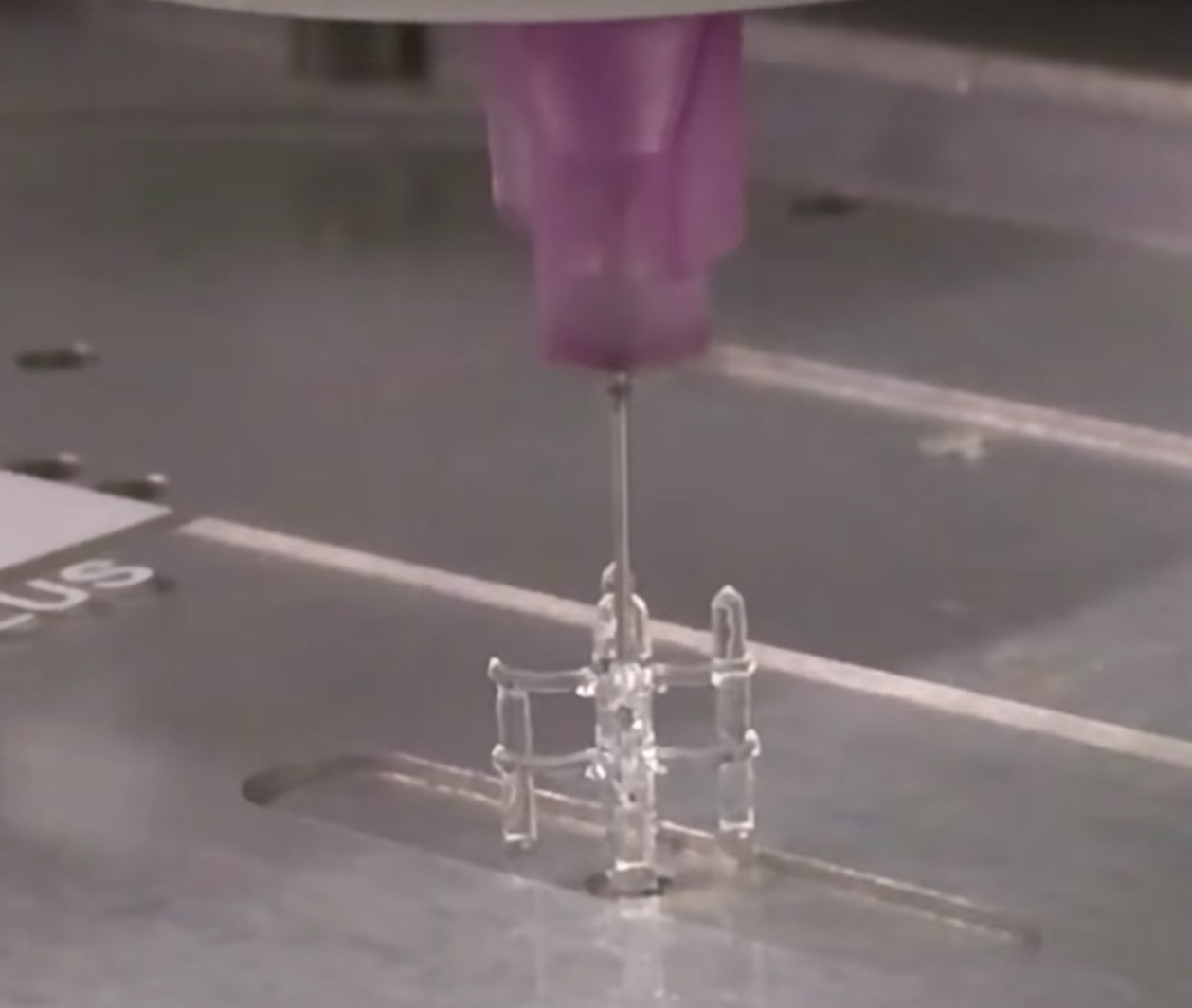

Their approach is two-fold. First they 3D print a structure in cartilage, which is impregnated with adult stem cells. The stem cells begin growing true bone material in the shape of the cartilage structure. Evidently the cartilage provides an excellent medium for growing bone.

Here we see a video of the process.

The implications of this development are strong, as current bone replacement methods involve grafting transplants, either from a donor or from one’s own body. Both have significant challenges and drawbacks.

If it proves feasible, the AMBER approach could enable bone replacements for very complex structures, such as the jaw or face.

This may eventually become quite important, as there are apparently 2.2 million bone grafts performed each year around the world.