I’m looking at a curious 3D printing system called “Print A Drink” and wondering where this approach could go.

It’s a 3D printing process that could be used in other, more powerful ways: Print a Drink is a system where edible droplets are injected into a clear liquid drink to form an interesting 3D pattern.

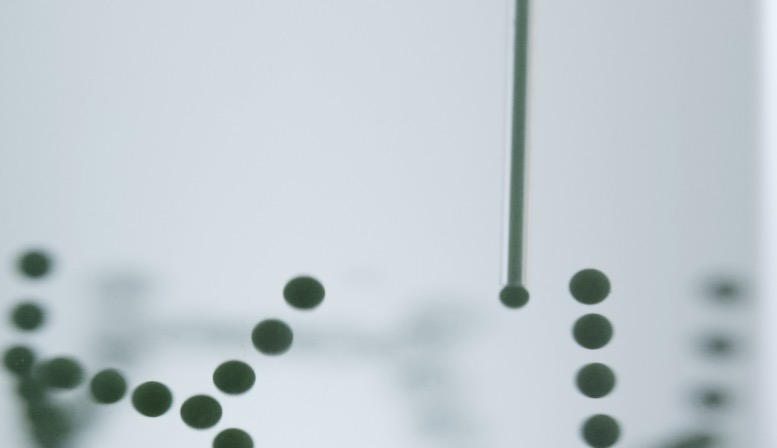

Here you can see the needle-like injector depositing spherical droplets of “something” into the drink.

The result, shown here is pretty impressive and could be something of interest to bars and pubs worldwide. Since the drops are few the printing process is likely very rapid and could be actually practical within a customer environment.

The project was Benjamin Greimel at the University of Linz in Austria. They explain:

PRINT A DRINK combines methods from robotics, life sciences, and design to explore a completely new field of 3D-printing. Rather than building up objects layer by layer, the process uses a high-end KUKA Robots to accurately “inject” microliter-drops of edible liquid into a cocktail. Within a minute, PRINT A DRINK can build up complex 3D structures in a wide range of drinks – creating fascinating augmented cocktails using only high quality ingredients.

It’s a very cool project, but I am quite inspired by this approach. It may in fact be a new type of 3D printing not yet explored by others. We’ve seen approaches using extruded plastic, powder fusion, particle melting and others, but never like this.

Imagine if this process was transformed into an object producing system: a liquid holds up arbitrary 3D structures that are quickly injected into position like Print a Drink. Then, either a chemical, photo or heating process solidifies the deposited material. The liquid is drained, baked or boiled off to release the object.

This might actually work. Is anyone investigating this approach? Are you allowed to talk about it? Do you have to kill us if you tell?

Via Print a Drink