3D Platform has long been known as a producer of “huge” 3D printers, but the word “huge” will have to be replaced after this announcement.

Their flagship product, the 3DP Workbench, was a well-received 1m-sized 3D printer, far less costly than most industrial alternatives. It was essentially a highly-tuned, scaled up version of a desktop 3D printer. It even uses the same spools of plastic that desktop machines consume, although for printing large objects you might need more of them. Quite a few more.

But now that’s all changed with the introduction of two brilliant new 3D printing concepts.

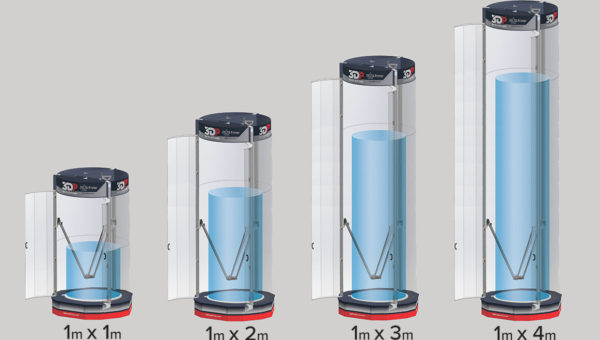

The first is the 3DP Delta Additive Manufacturing Series. As you might guess from its name, it’s a delta-robot style 3D printer. These have been around in the industry for a while, but never at this size.

The 3DP Delta AM Series from 3D Platform comes in four sizes. The first size is large, 1 x 1m (cylindrical – this is a delta, machine, remember!) The next machines are 1 x 2m and 1 x 4m! But the largest is the 1 x 4m version. (For non-metric types, that’s an astonishing 13 feet tall!)

Previously, the tallest machine I’d seen was the also very tall Leapfrog Xcel, which requires a ladder to get to the top. It seems that the 3DP Delta AM Series will require an elevator!

For 3D printing the tallest objects, this is the biggest you can get.

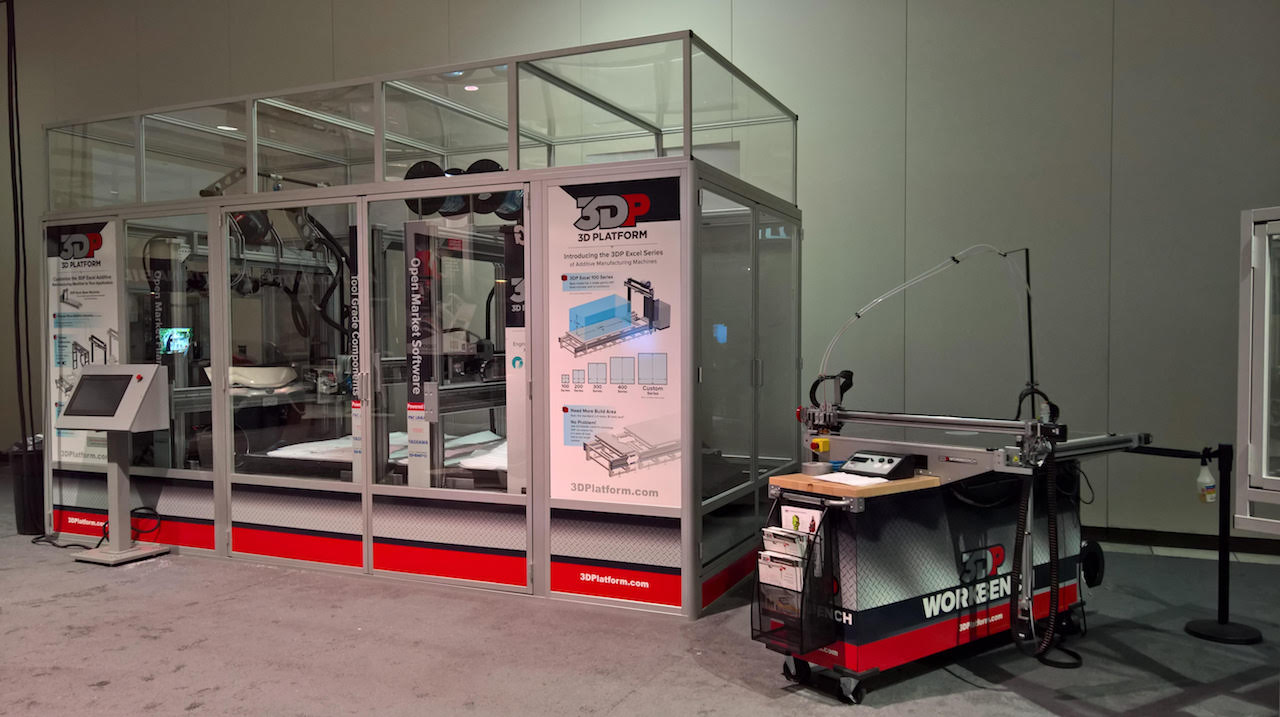

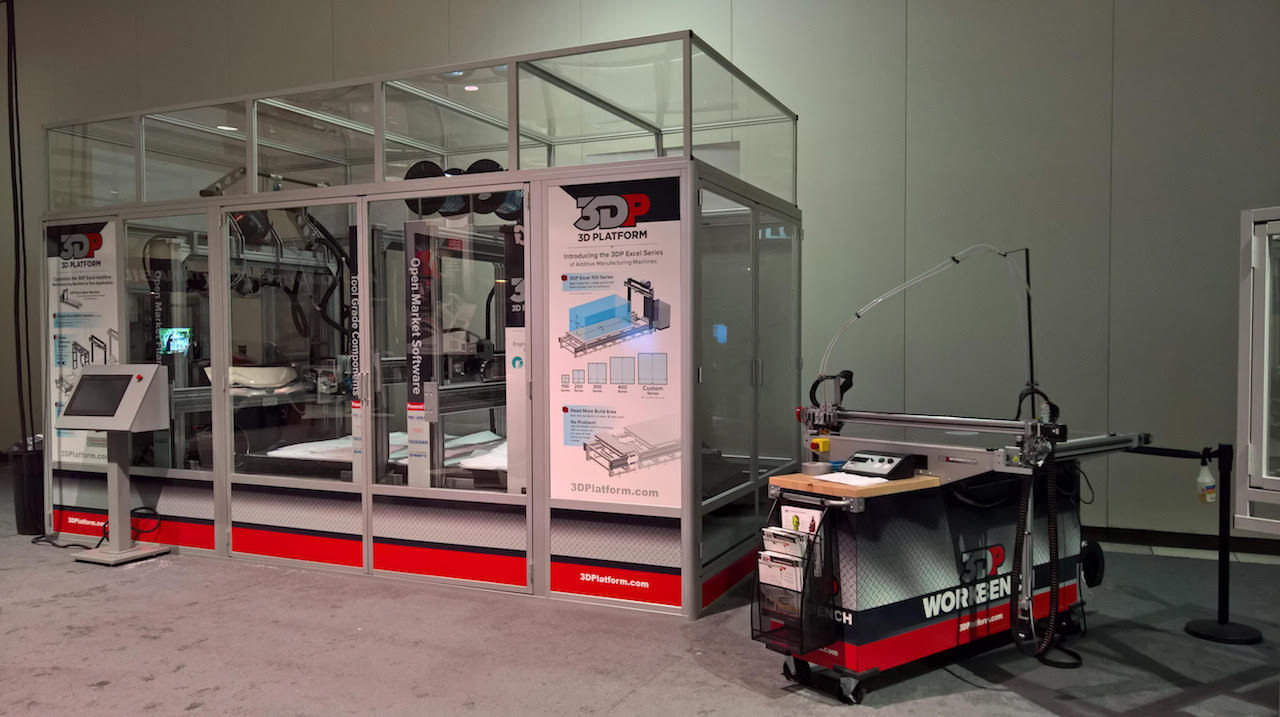

The second concept unveiled by 3D Platform is more intriguing. It’s called the 3DP Excel Additive Manufacturing Series, shown at top.

The concept is a kind of gantry system on which they can hang not only 3D printing extruders, but also CNC equipment, creating a hybrid capability. You can also install robotic equipment to add the ability to do assembly functions.

The 3DP Excel AM Series starts at a similarly large 1.2 x 1.2 x 2.4m build volume, which is quite large. That’s the “100 Series” size. They also offer a 200, 300 and 400 series that are 2m, 3m and 4m on a side. And they can also custom build even larger if requested.

There’s another extremely important feature on this machine: it’s throughput. As you might imagine, the larger the print, the longer it takes to complete. That’s been the case, more or less, with 3D printers ever since they were conceived. But 3D Platform has broken that barrier with some very interesting developments.

The Series 100 can use a 6mm spooled filament for printing (as opposed to the previous 2.85mm filament) and it uses larger sized nozzles. This enables greater ability to deposit material.

But that’s not all. The 3DP Excel AM Series can use standard plastic pellets as its input material in addition to filament. This is not only less expensive but also enables the delivery of even more material during printing.

In fact, with a huge 4.5mm hot end nozzle, the Excel can deposit up to an amazing 55kg of material per hour! Theoretically in a single day this machine could print up an object weighing more than a tonne! No other 3D printer can do this.

I can’t wait to get a look at these new machines.

Via 3D Platform (Excel) and 3D Platform (Delta)