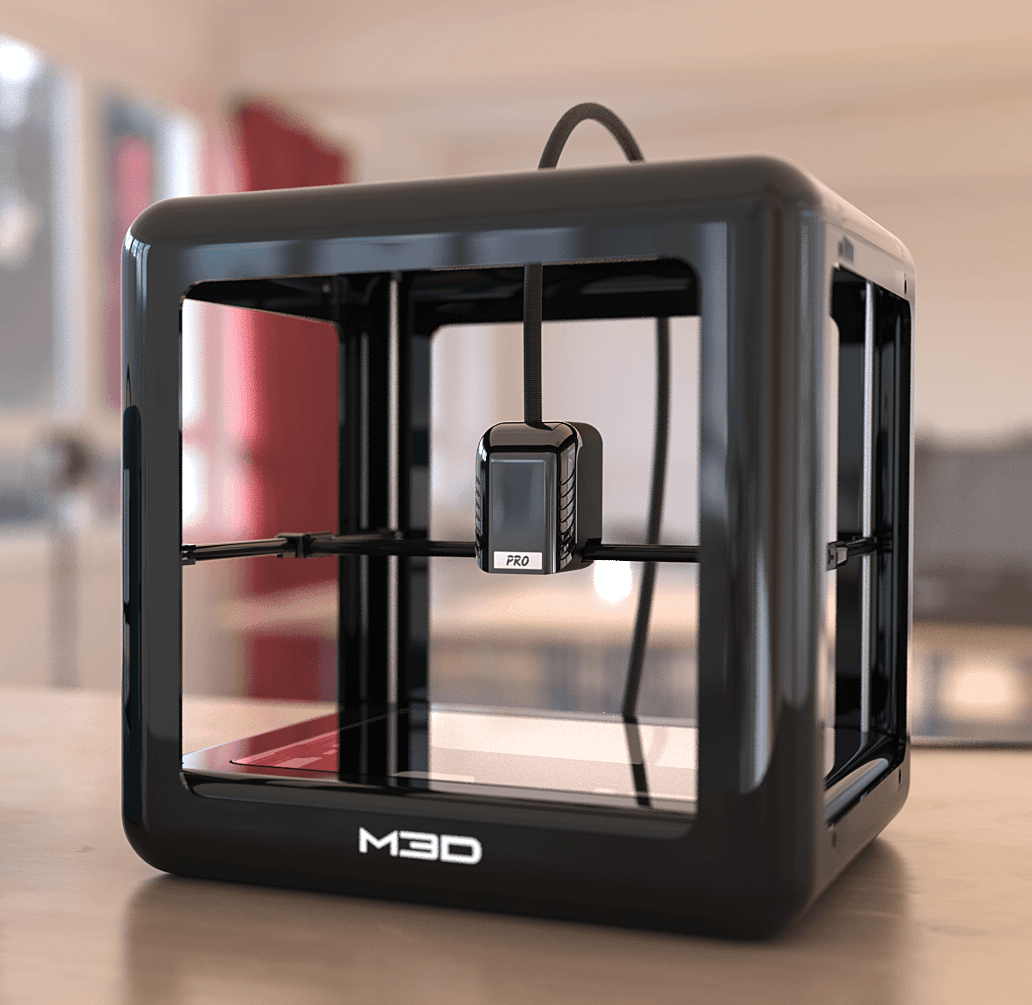

Remember the M3D Micro 3D printer from years ago? This machine has now grown into the new M3D Pro model that just happens to be launched today.

We previewed the M3D Pro a couple of months ago, but today there’s more information available on the company’s Kickstarter page, where they’re officially launching the new device to the public.

The original M3D 3D printer was a very low cost unit, and to be honest, it did not have a great deal of fancy features. But nevertheless, it proved to be extremely popular and ended up being one of the best sellers in the low-cost desktop 3D printer market.

But with such sales comes a great deal of user experience, technical learning and most importantly increased financing. Combine these factors together and you get a new, more advanced machine, the M3D Pro.

The new machine has been designed largely around direct user feedback on their experience with the original machine. As such, there are several interesting new features, many of which we covered in our original breakdown.

Early desktop 3D printers all suffered from the same phenomenon: poor reliability. While there have been multiple approaches to this dilemma, M3D has taken a very unusual approach. They explain:

Today’s 3D printers operate on faith that they will run properly for many hours after hitting print. We realized that the 3d printer needs to be totally redeveloped so that every single aspect of the printer can be measured so that it can be corrected in real-time. Our solution for this problem was to add full sensor feedback – on everything we could. Temperature, voltage, current, position, speed, bed leveling – and more. Over two-dozen sensors in total.

While other 3D printer manufacturers do some of this, I’ve not yet seen this as a foundational philosophy from any other company. Two dozen sensors is a huge number for such a low-cost machine. I’m not certain there’s that many sensors in some of the high-end equipment I’m familiar with.

It appears they have five temperature sensors: two on the extruder mechanism, and three on the brand-new glass heated print surface. There are also a number of positional sensors. Power, current and voltage sensors are also present.

But sensors are not so important unless they are leveraged in some way. This is what the M3D does. For example, their motion system employs lighter stepper motors, which normally might be a problem. Instead, the sensor network is used to carefully tune their movements, providing an ability to use lower-cost components but still provide a reliable solution.

Similarly, they’ve developed an advanced design for their glass print surface, which heats extremely efficiently. This permits them to use a lower-cost power system as compared to other machines, again while still providing the reliability. Of most interest to users will be the rapid heating due to the efficient design: they say it heats up to operating temperature in less than a minute.

By the way, that heated print surface is quite important as it takes the machine from a PLA-plastic-only world into one where many different types of materials can be 3D printed.

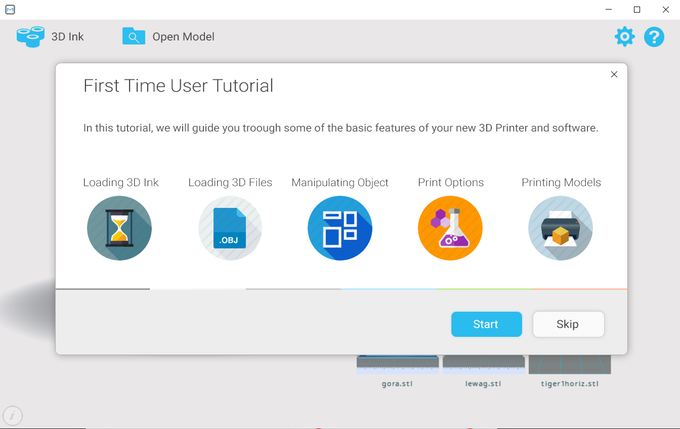

The M3D Pro’s software interface now includes a comprehensive tutorial mode that should make life a bit easier for the less technically inclined customers.

As was their first 3D printer, the M3D Pro also is open to any 1.75mm plastic filament. There are no “chipped” cartridges and the operator will have complete freedom to choose filaments from any vendor. This, combined with the heated print bed, provides a very versatile platform for printing many different materials.

Finally, they’re providing a near-unprecedented two year transferable warranty on the machine. A few companies offer a one year warranty, and some offer only 30 or 90 days. Many companies offer NO warranty at all!

If that’s not enough, the company has published a list of the features they’re developing for future enhancements to the M3D Pro, and they look extremely interesting. Some of the items noted in their lists:

- Higher extruder force

- Precision linear rods

- Power saving (ability to recover from power failure?)

- Skip recovery (detection and recovery from belt slippage)

- Automatic bed calibration

- Networked printer

- Self troubleshooting

There’s much more in the list, making this machine pretty attractive.

But wait – I haven’t yet mentioned the most important feature: the price. As you recall, the original M3D Micro was a very low-cost machine, and that doesn’t change much with the M3D Pro.

For the Kickstarter, the earliest birds will get one at the ridiculously low price of USD$399. After the initial quantities are consumed, which could happen very quickly, the price slowly rises to USD$499 and up. Get one fast, if you can!

Via Kickstarter and M3D