The other week we had a really close look at the FELIX Pro 1 and found a couple of very interesting features.

Every 3D printer company hopes to differentiate their product by introducing new features that aren’t found elsewhere. FELIXPrinters is no different. Their FELIX Pro 1 desktop 3D printer, introduced late last year, is their most advanced device thus far.

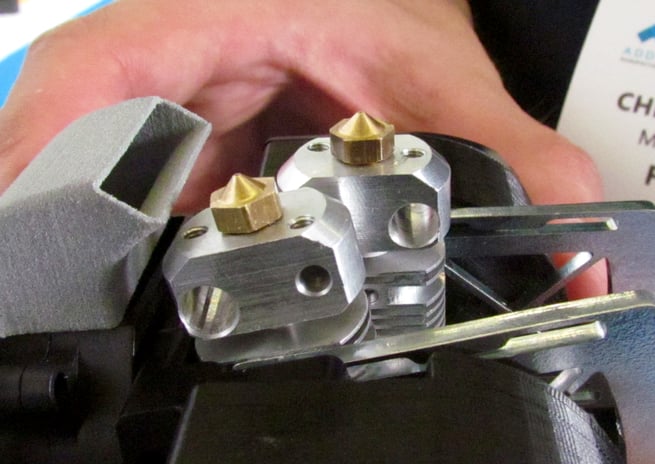

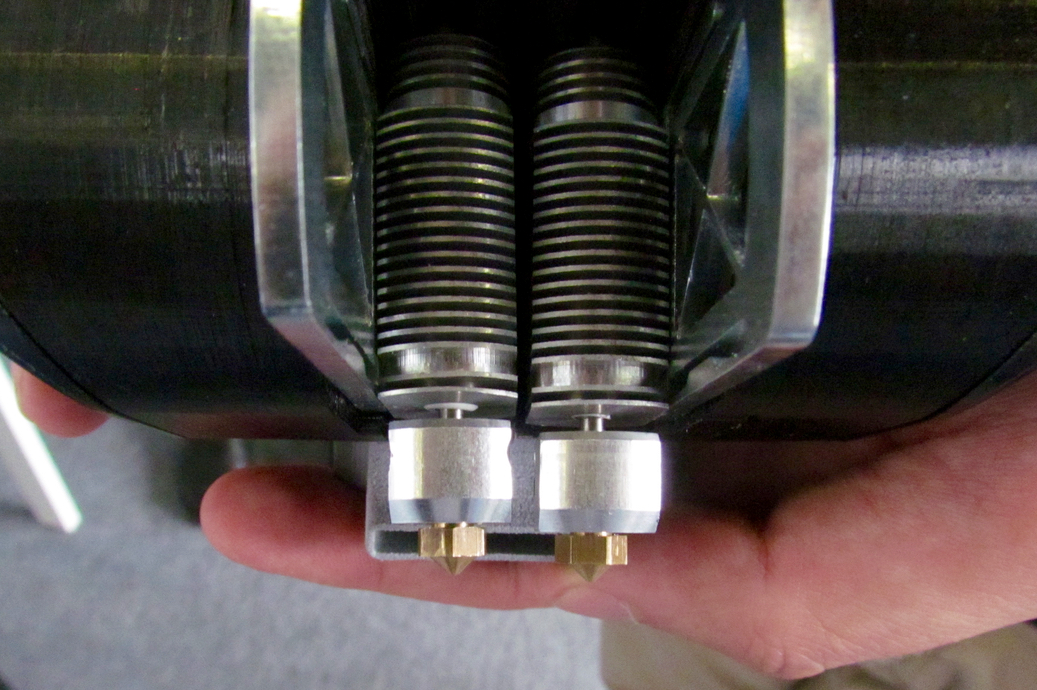

I saw two very interesting features on this machine, the first of which is the “swing extruder”.

This feature addresses a problem so often encountered when using dual extruders. In the typical arrangement, two hot ends are closely positioned and move about the build platform in tandem. It’s advantageous to have them as close to each other as possible to ensure the maximum possible build volume on the X-axis (you lose the distance between the hot end nozzles).

But this proximity causes a frequent problem: should your extrusion end up slightly higher than the current layer, perhaps by being brought up a bit by a retraction operation or pushed up by a slight warp. This protruding material can sometimes get caught up on the non-extruding hot end, causing unexpected pressure on the incomplete print.

In some cases, this effect can literally rip the print right off the platform and cause the entire print operation to fail. If the dislodged print happens to fall into the motion system of the 3D printer, you could even cause significant damage to the machine.

But none of this can happen on the FELIX Pro 1, because it uses a special mechanism to shift the height of the unused extruder.

Check out this image showing the two hot ends: they’re not at the same level. Sure, it’s not very much, but this is sufficient to avoid almost all protruding material.

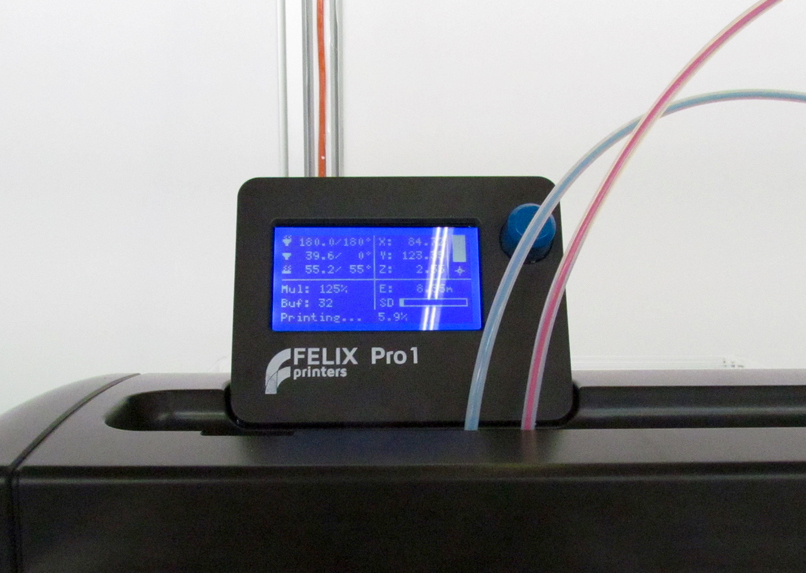

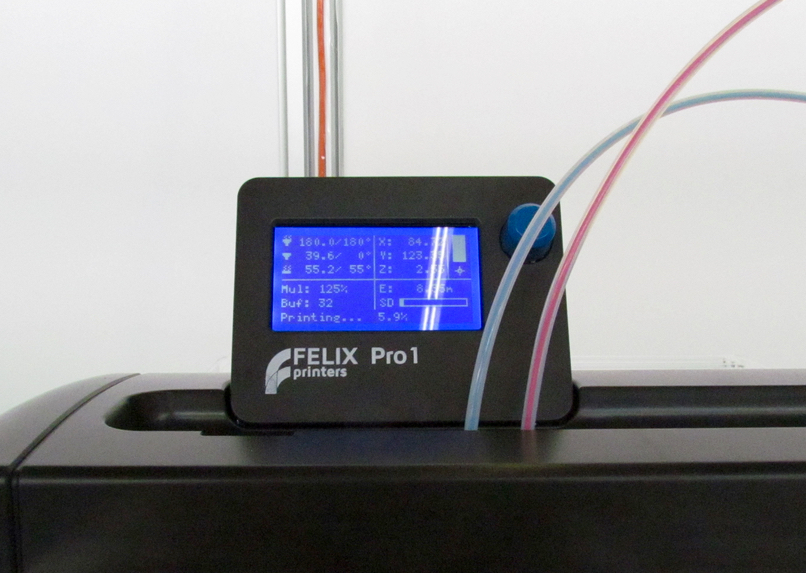

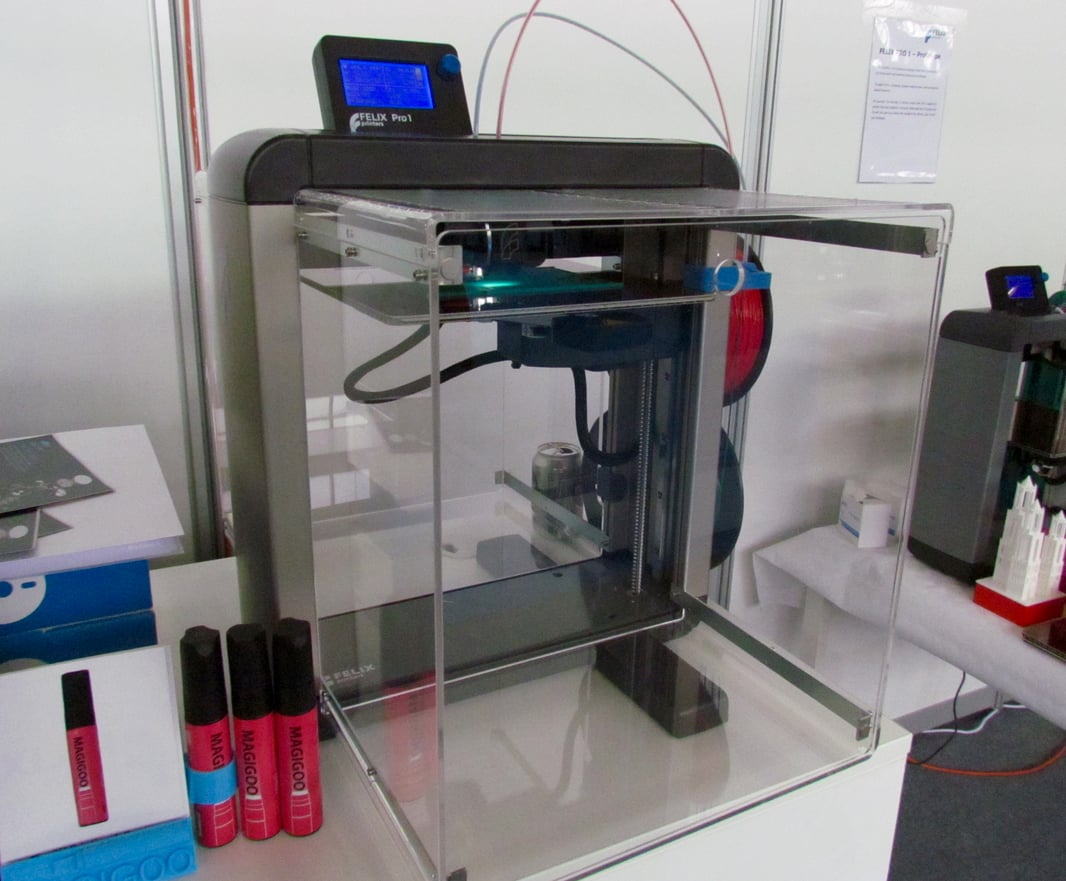

The second feature is an accessory enclosure. Normally, the FELIX Pro 1 is an open-style machine where the ambient atmosphere can flow into the build volume. An enclosure can capture incidental heat from the build platform and raise the ambient temperature within the enclosure. This higher temperature will make prints much more reliable and enable more practical printing of tricky plastics such as ABS.

Here we see the enclosure at top, where there are vents to permit escape of excess heat. Also note the smart entry slot behind where the filament can freely enter the chamber without compromising the enclosure too much.

The enclosure has another interesting side effect: it prevents kids and pets from accidentally getting too involved in a live print operation. It’s possible this feature alone could encourage sales of the FELIX Pro 1 in the education market.

The FELIX Pro 1 may be made by a small Dutch company, but it’s quite a versatile machine.

Via FELIXPrinters