When we met with Ultimaker last month the company was excited to explain one of their customers had discovered a new 3D print use case: portable 3D printing.

We wrote about this concept somewhat in a previous post, but there’s more to the story.

To catch up, the scenario they described involved a customer taking their Ultimaker to a project site where they plugged it in and were able to quickly 3D print a series of iterative prototypes that rapidly led to a successful conclusion. In that case, it was developing a custom air intake for a sports car, which was only available for testing during a brief weekend period and could not be moved.

The idea of taking a 3D printer onsite for work is interesting, as it could short-circuit several steps in a typical project workflow:

- Travel time to ship 3D models and prints between the site and the normal printer location are eliminated

- Interactions with the customer occur instantly when the print completes

- Onsite testing occurs immediately

- Measurements can be taken or concepts examined onsite as required without delay; no lengthy conversation delays required

It’s a very interesting business concept, and while it would be applicable in only certain situations, those would certainly benefit.

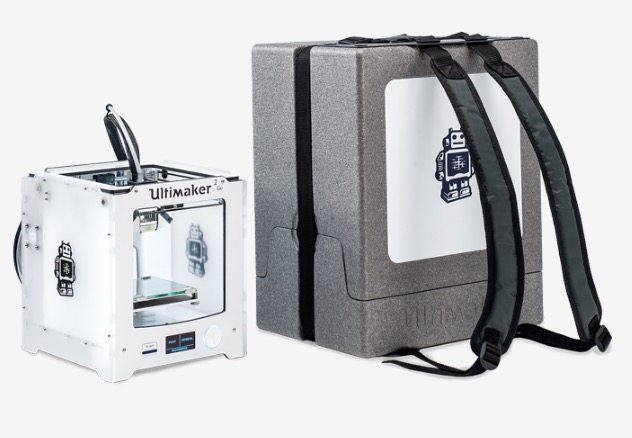

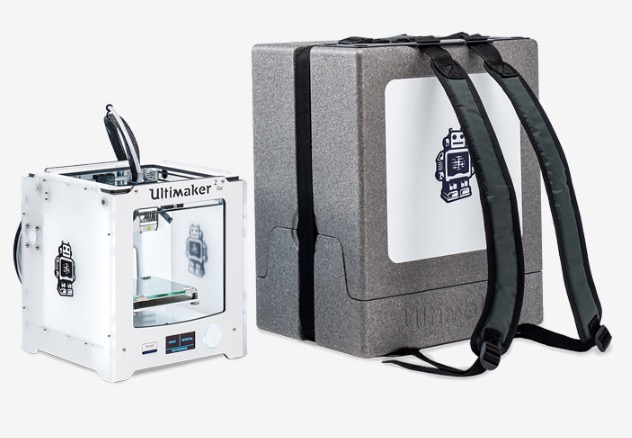

Then I noticed that Ultimaker now sells a backpack to accompany their Ultimaker Go 3D printer – you remember, the portable unit?

It seems they really believe in this portable 3D printing concept, which hasn’t really been fully exploited by any other 3D printer vendor as far as I know.

But they need to do one more thing: make a larger backpack for the Ultimaker 2+.