Looking for a low-cost SLS 3D printer? You might want to check out the Sinterit Lisa.

The Lisa is made by Sinterit of Krakow, Poland, where it was announced only a few weeks ago as their very first product. It’s a relatively small volume 3D printer that uses a powder / laser process to print very high quality objects in durable material.

The machine’s build volume is a reasonable 150 x 200 x 150mm, which should meet the size requirements for a great many objects. Layer thicknesses can be as small as 0.06mm, making for some fine results.

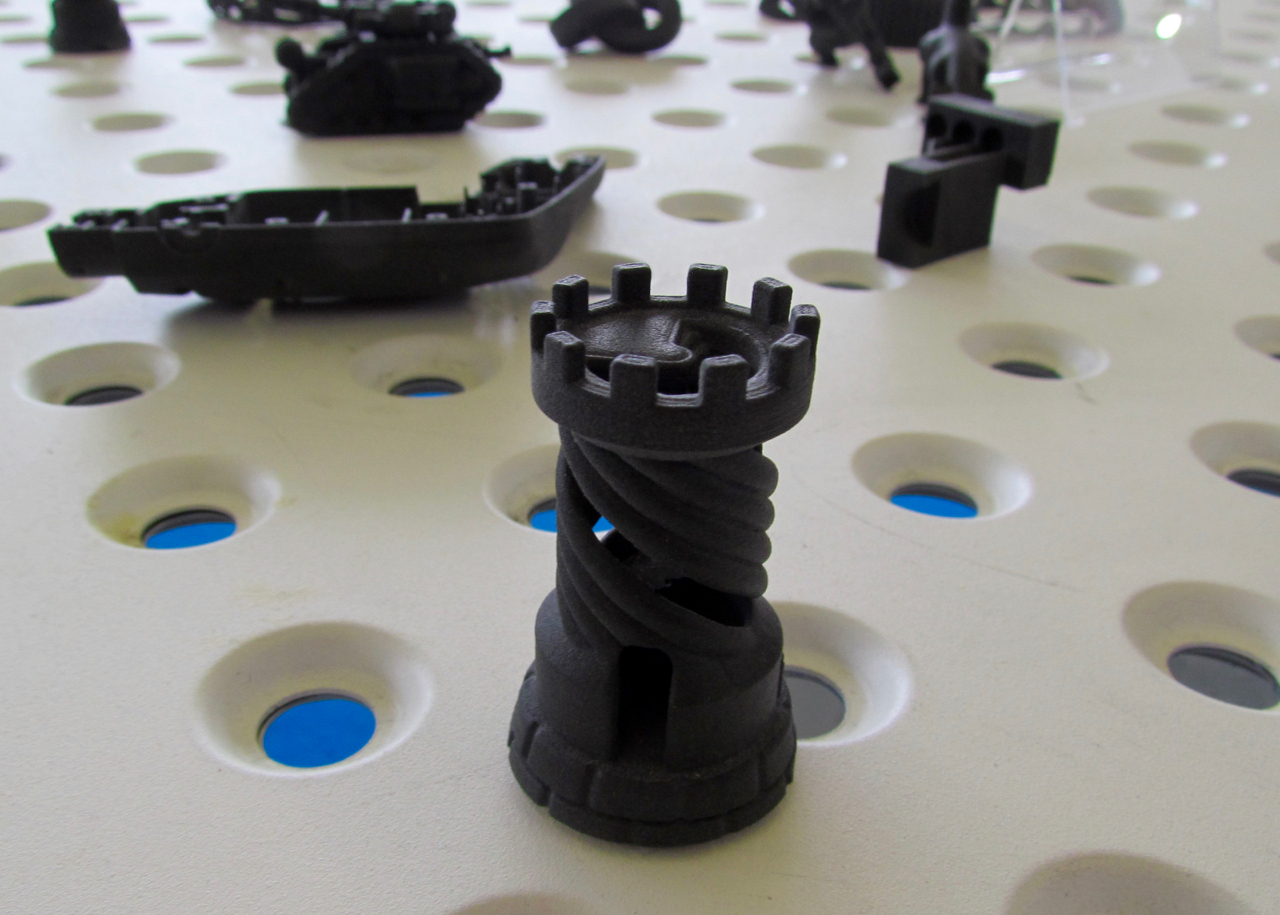

Here we can see the famous 3D printed rook, used by many companies to demonstrate resolution capabilities. In my opinion, the Sinterit Lisa passes the resolution test very well.

Here is a Nervous System-style bracelet, of equal quality.

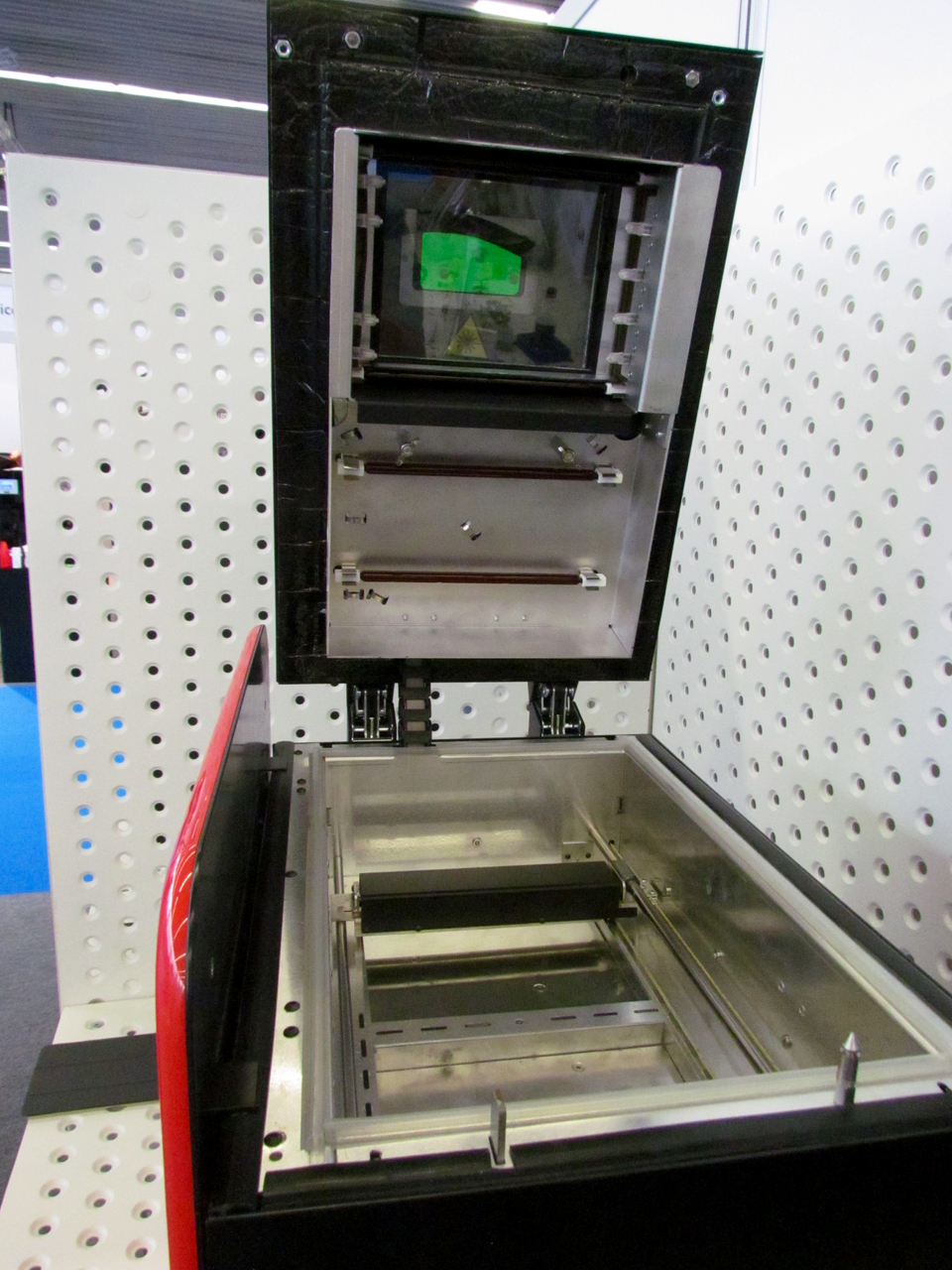

Inside the Sinterit Lisa is a laser that is the key to their price advantage. While the more expensive machines use a galvo laser system in which the high power laser remains stationary and the beam is directed by a complex system of mirrors, the Sinterit Lisa uses a less expensive diode laser that is sufficiently light to move around itself and directly blast the powder bed without the need for mirrors.

This approach simplifies the mechanics somewhat and helps arrive at their list price of €12,800 (USD$13,800), which while higher than consumers or hobbyists would pay, is vastly less than the high-powered SLS machines you can obtain from other vendors, which can cost in the six-figure range.

But the machine is not simply a laser and a powder bed. The Lisa’s design includes the ability to precisely control the temperature of the components to ensure appropriate quality. There are independent heating controls for the piston, cylinder, feed bed and print bed.

How fast is this machine? The specifications say it can 3D print as much as 20cc per hour, or about 10mm per hour, depending on model geometry.

I asked about the ability to reuse powder, which is an issue in some other SLS-style machines, and was told that 1kg of powder is sold for €110 (USD$122) and can be reused if not fused into the print. However, they also explained that you should have at least 25% “new” powder in the machine at all times to ensure quality.

The Sinterit Lisa also comes with dedicated software to slice 3D models and operate the machine, as well as WiFi and an onboard camera to monitor activities.

Currently Sinterit offers only black PA-12 nylon material, hence the dark colored sample prints shown above. However, they explain they’re working diligently on producing white nylon very soon.

I suspect this machine will be a huge success, not only because of the quality, but because of the price. It’s perhaps the least expensive way to obtain a professional SLS 3D printer. But you’d better hurry because we’re told they have “many orders” and a lead time delay is growing. Apparently they are frantically hiring assemblers for their manufacturing plant to keep up.

My only negative on this machine is that you can only get it in a red cover. Why can’t we have blue?

Via Sinterit