Netherlands-based Innofil3D has released a video showing their new “Pro1” 3D printer filament that has some very strong characteristics.

I’ve always thought there should be significant innovations in 3D printer materials as well as the machines that use them. One of the companies pushing the envelope in this regard is Innofil3D, who have just announced a new product line dubbed their “Innofil3D Professional Series”, with the flagship product “PRO1”.

They call it “Professional” because they’ve been able to develop a new plastic that offers these advantages over common 3D print material:

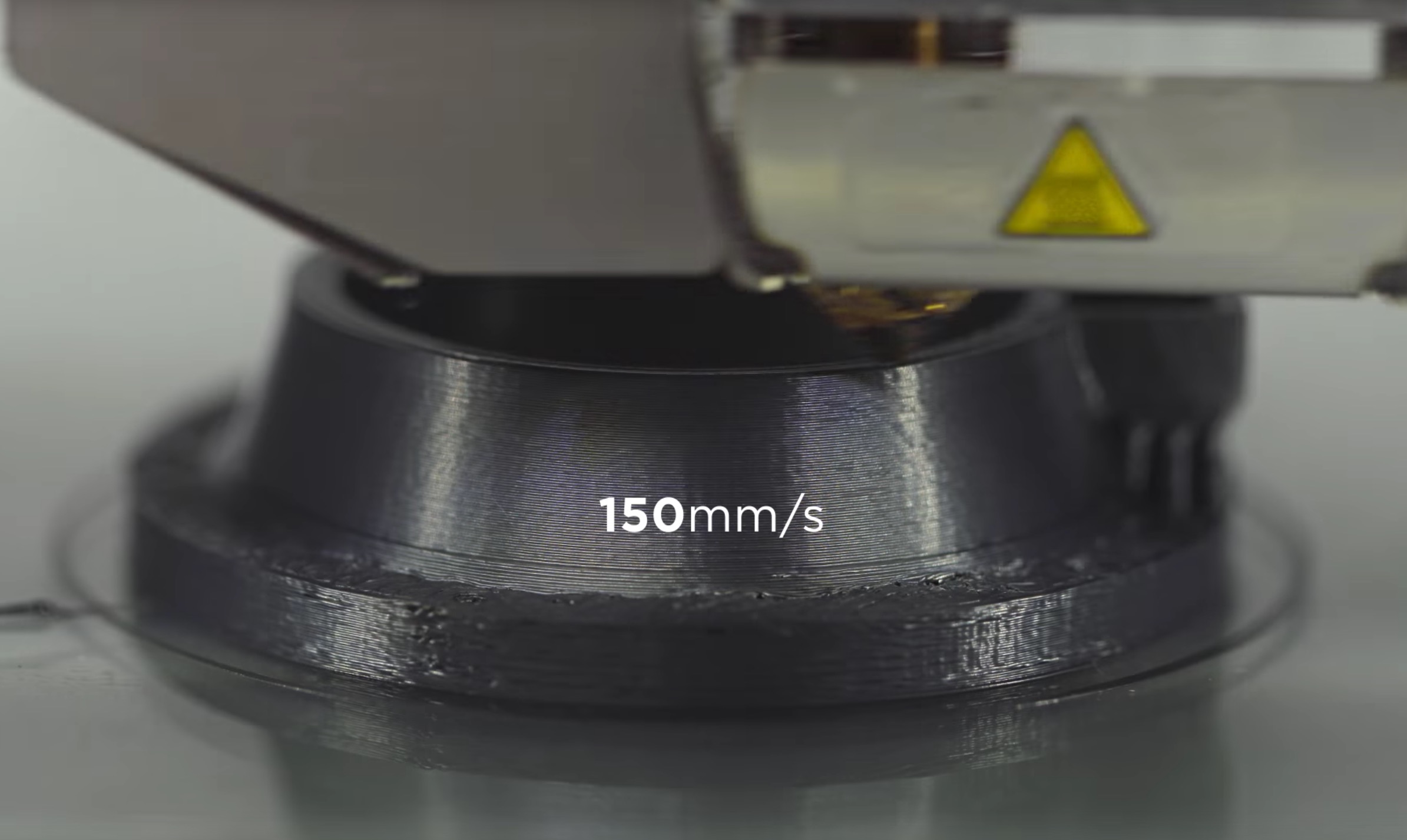

- SPEED: Reduce your printing time with 30%-80%, (subject to printer and object limitations)

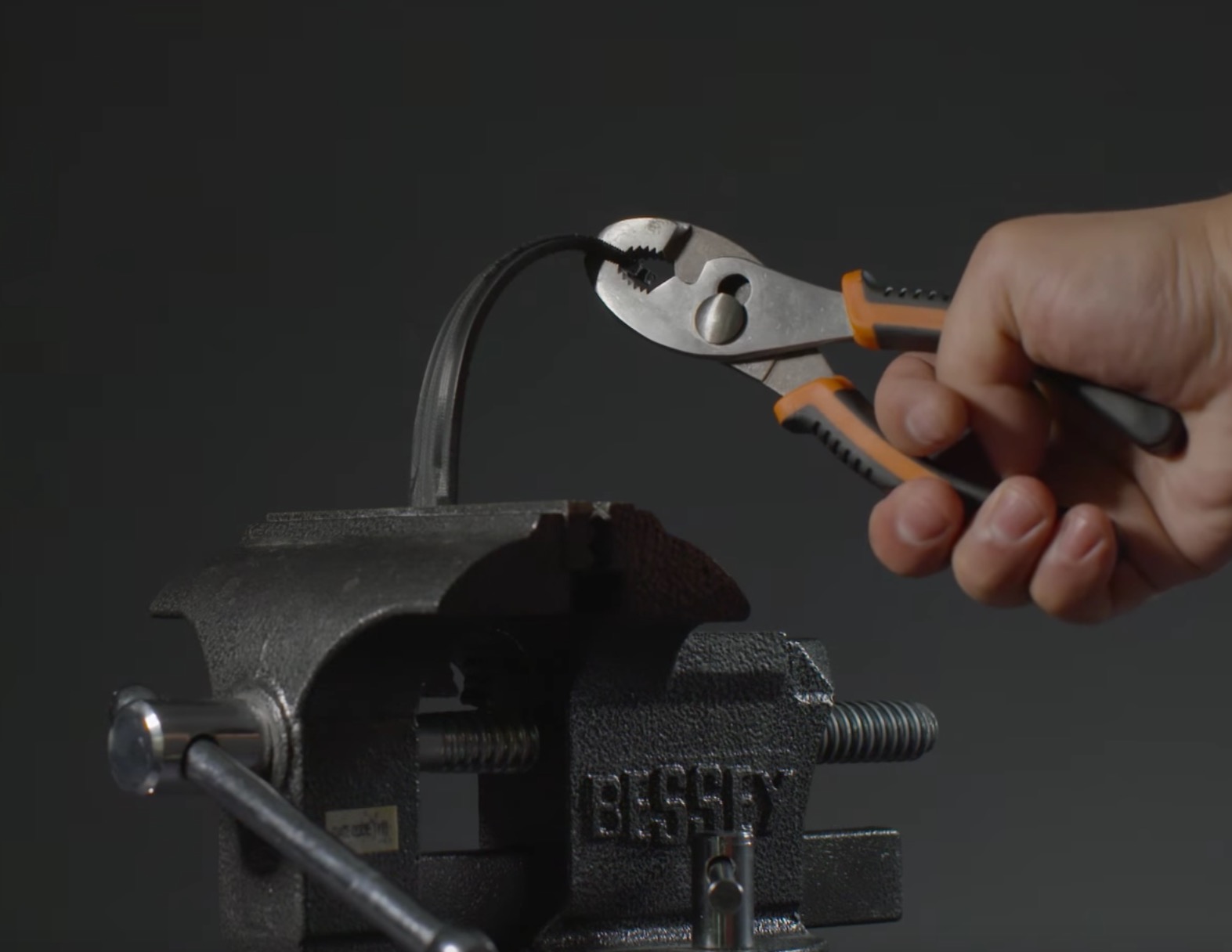

- STRENGTH: Excels overall beyond printed ABS in mechanical property

- VERSATILITY: One filament that can be tuned towards blazing speed and excellent surface finish

- CONSISTENCY: Truly consistent filament, also between colours and batches, it will perform as expected, every time.

It’s a very enticing combination of factors, and perhaps the first time I’ve seen a 3D printer filament address the needs of both High Speed and High Strength simultaneously.

They say the PRO1 filament can be printed at up to 150mm/s, which is quite fast – although not as fast as the fastest plastic extrusion 3D printers. However, it would be interesting to try this material at even higher speeds.

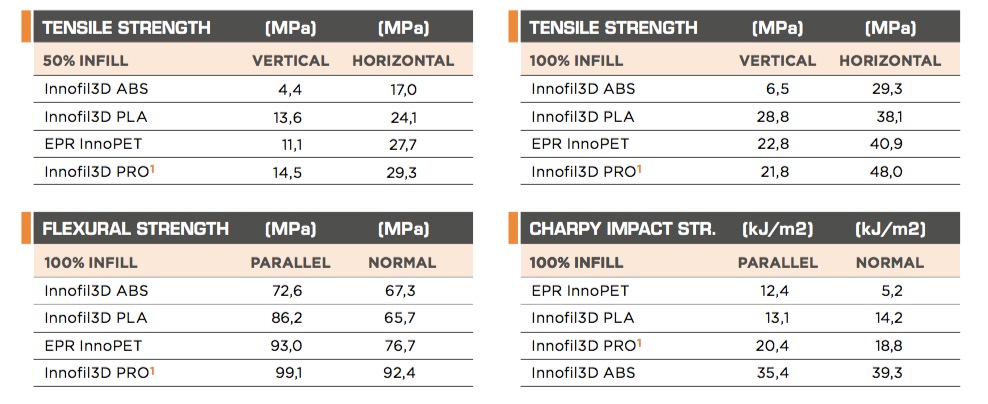

How strong is PRO1? Well, Innofil3D provides several different metrics, but in all cases it seems to be at least somewhat stronger, but in some cases, much stronger. Check out these statistics:

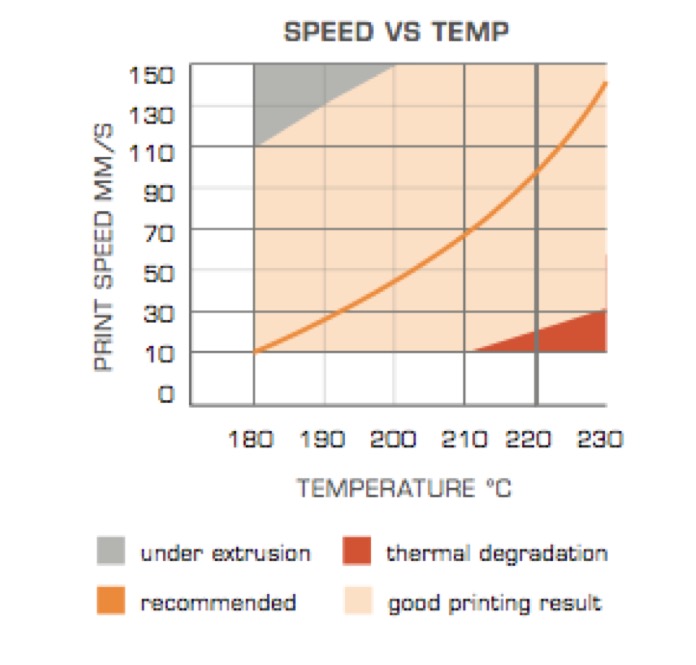

Another extremely interesting feature is the large temperature window in which PRO1 can successfully print. This diagram shows the thermal window:

This large window means that you can withstand a large variation in hot end temperature and still get a decent result, while other plastics have more precision required.

Of course, the filament also carries the expected high quality dimensions and coloration.

And did I mention it doesn’t warp (very much) or emit odors during printing?

Via Innofil3D