This is a big deal: a company has figured out how to perform automated operations on 3D printers.

The startup Tend.ai is actually all about the efficient training of robots, but was triggered by a need in the 3D print world.

The problem being solved is one that’s bothered me for many years: every single print operation requires human intervention, and sometimes very significant intervention. You must carefully remove the completed (or failed) print, restore the machine to pristine operational condition for the next print, and sometimes reload print materials, too.

It’s ALWAYS done by a human and poses a massive limitation on the capabilities of 3D printing. No matter how fancy a 3D printer gets, it always requires someone to watch it, load it, unload it and fix it.

I have been enamored of primitive 3D printing automation solutions, like MakerBot’s now defunct “automated build platform”, that would automatically unload the prints into bucket. That simple change transformed the little 3D printer into a true factory, capable of pumping out large quantities of items all by itself.

Sadly, that feature faded away into the 3D printing ether years ago.

But now Tend.ai has developed a cloud-based robotic training solution that could alleviate such concerns.

Here’s how it is supposed to work:

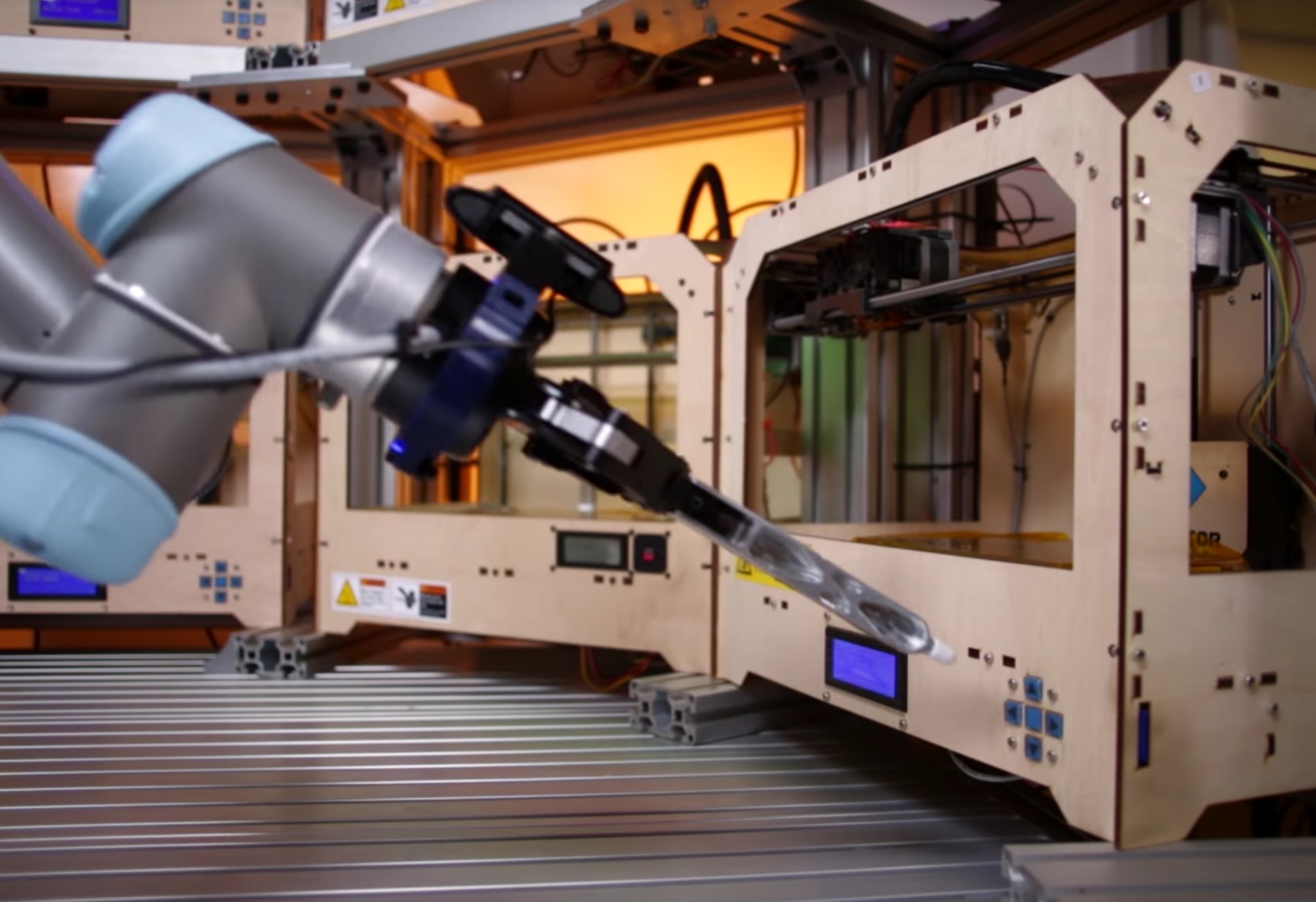

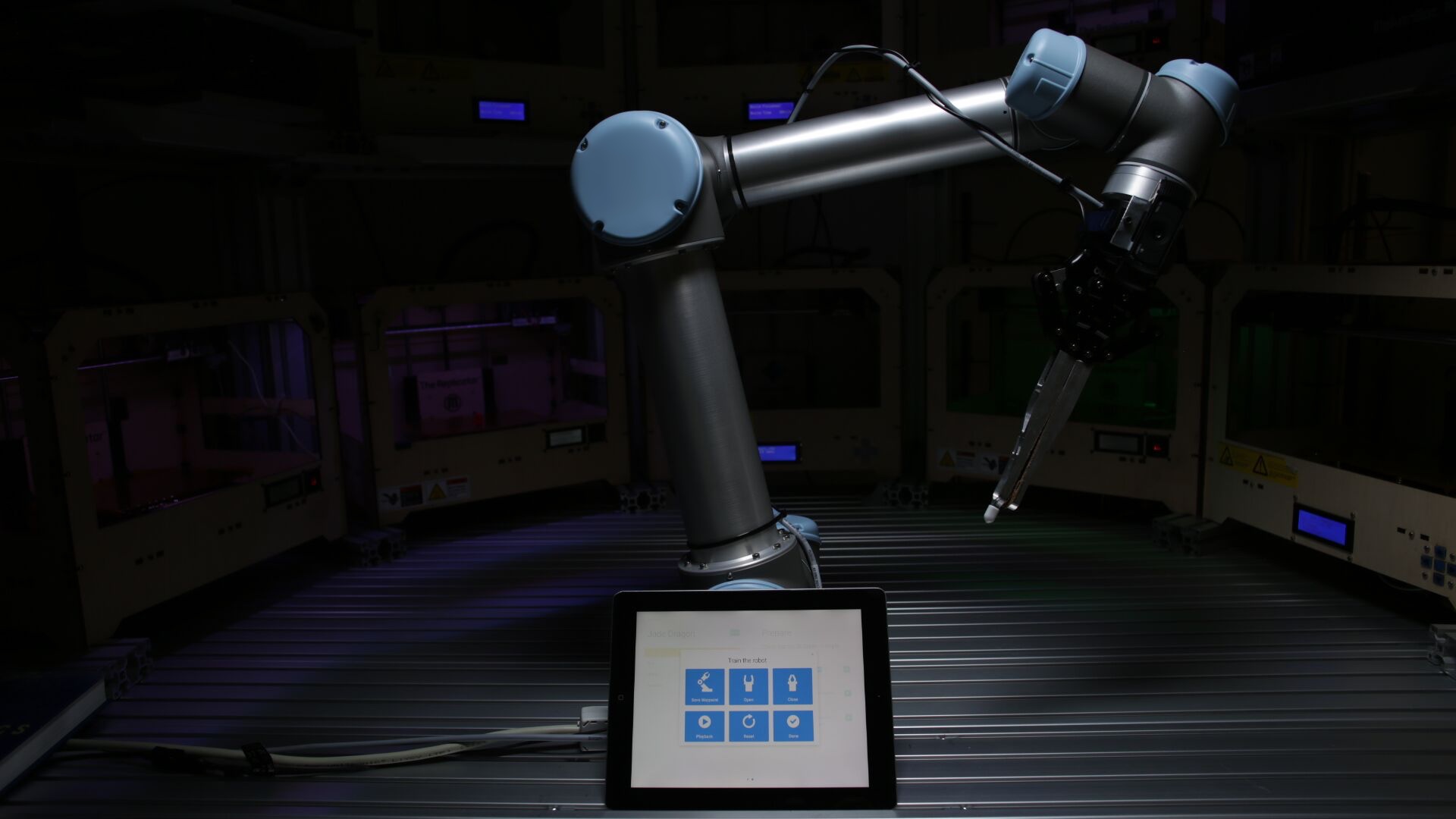

- Install a typical industrial robot near your 3D printer

- Attach a webcam to the active part of the robot arm

- Plug in the robot and webcam to a set-top box from Tend.ai

- Train the robot to perform the manual tasks required to operate the 3D printer

This video shows how it works:

It looks simple, but it’s likely more challenging. I can think of a two major concerns:

The robot will perform operations as trained – but will you be able to identify all the failure scenarios? What happens when one occurs that you missed? Could your equipment be damaged? Creating robust automation workflows is specific skill that not everyone has, so it’s up to Tend.ai to provide as much assistance as possible.

Will ALL operational tasks be do-able by a robot? Could a robot remove the print from the bed? If the print is loosened merely by a cooling period, then perhaps. But if it requires the print bed to be removed and print pried off with a scraper, that’s a lot more difficult. Oh, yes, the print bed would have to be replaced accurately, too.

But if Tend.ai can get around those challenges, there are a number of advantages that I can think of:

Unattended operations becomes more-or-less a reality, however given the state of reliability of many desktop 3D printers, I’d simultaneously ensure there are smoke detectors, heat sensors and automated fire extinguishing gear present. Hmm, maybe the robot could operate those, too?

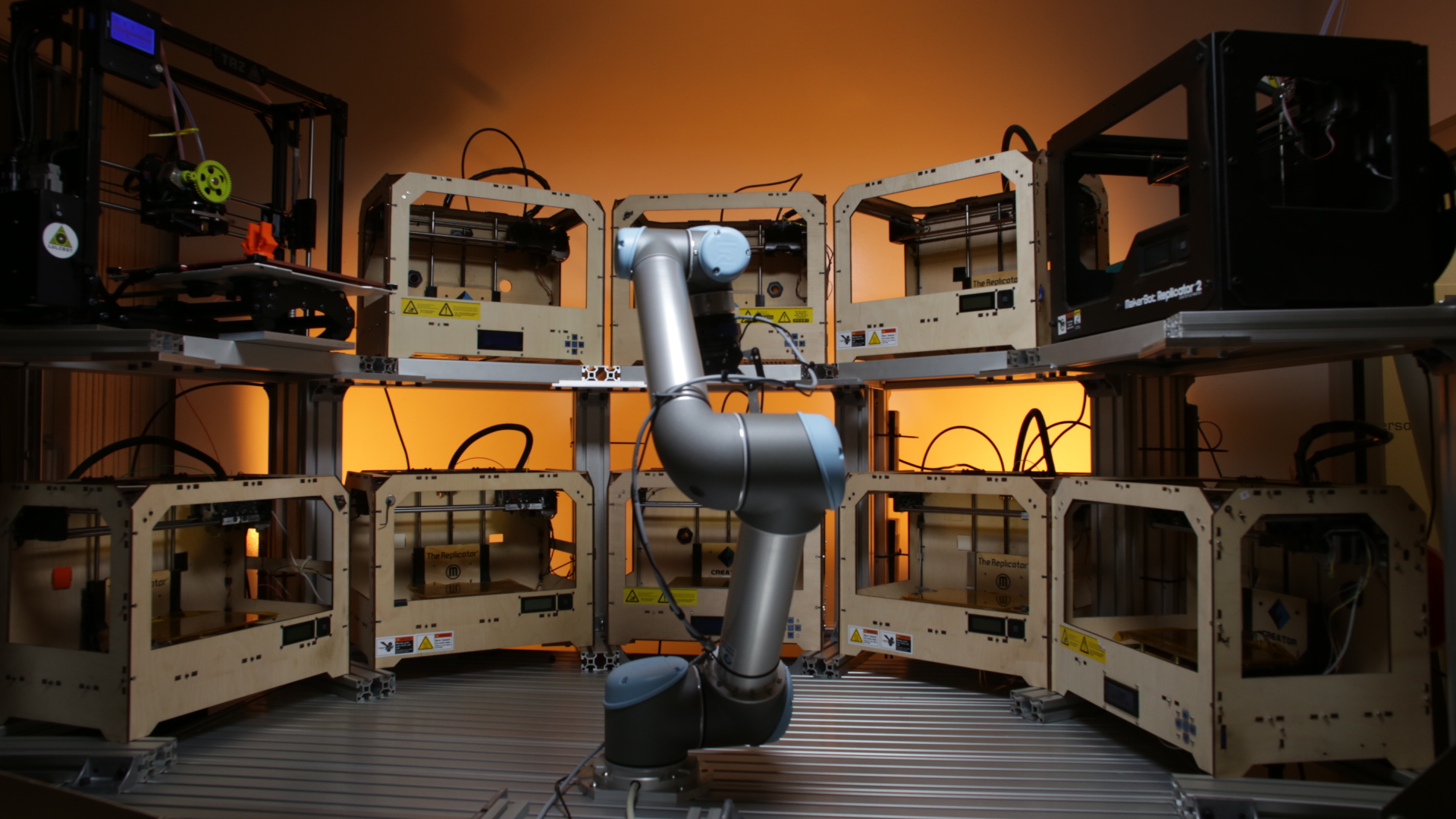

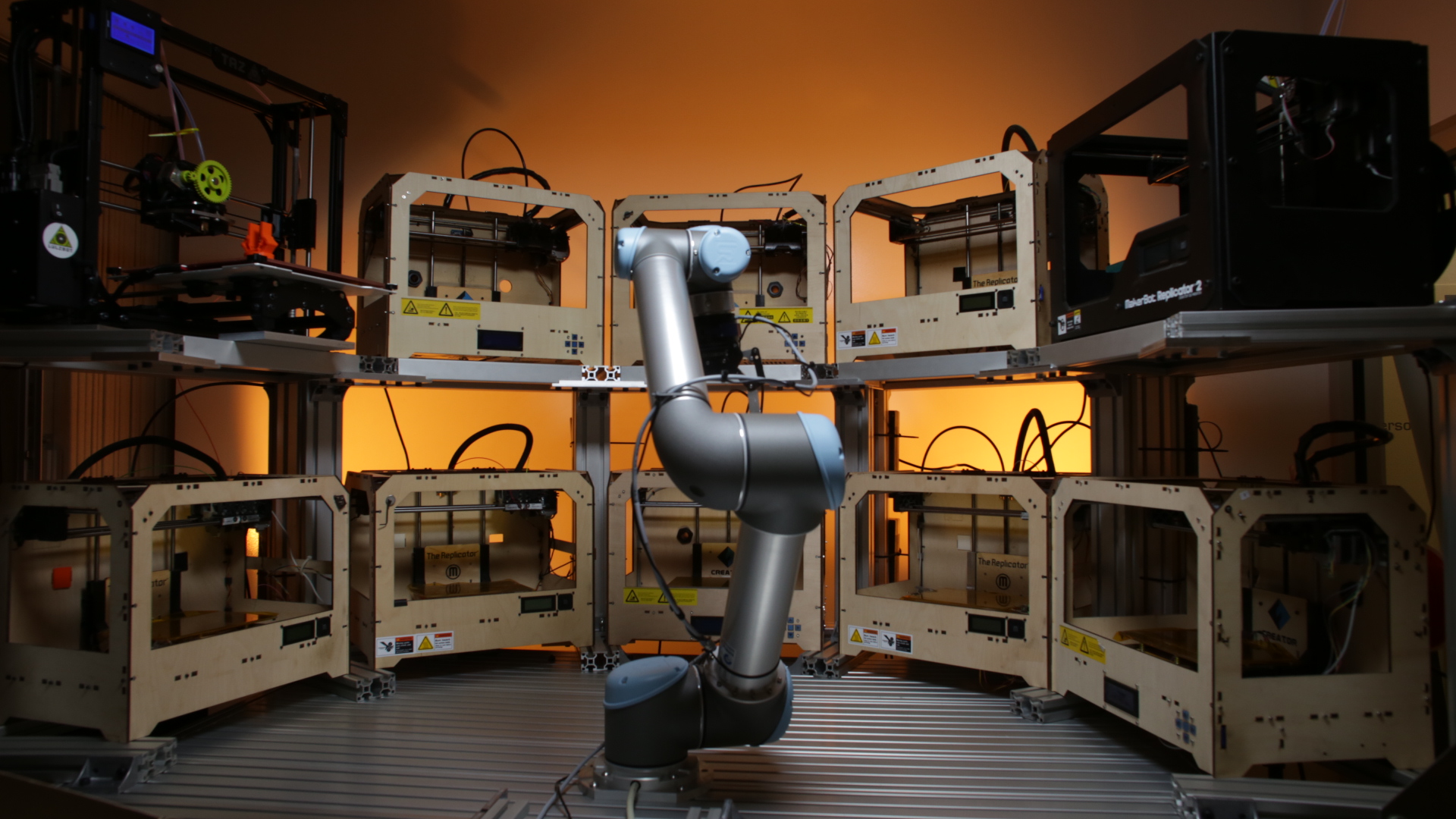

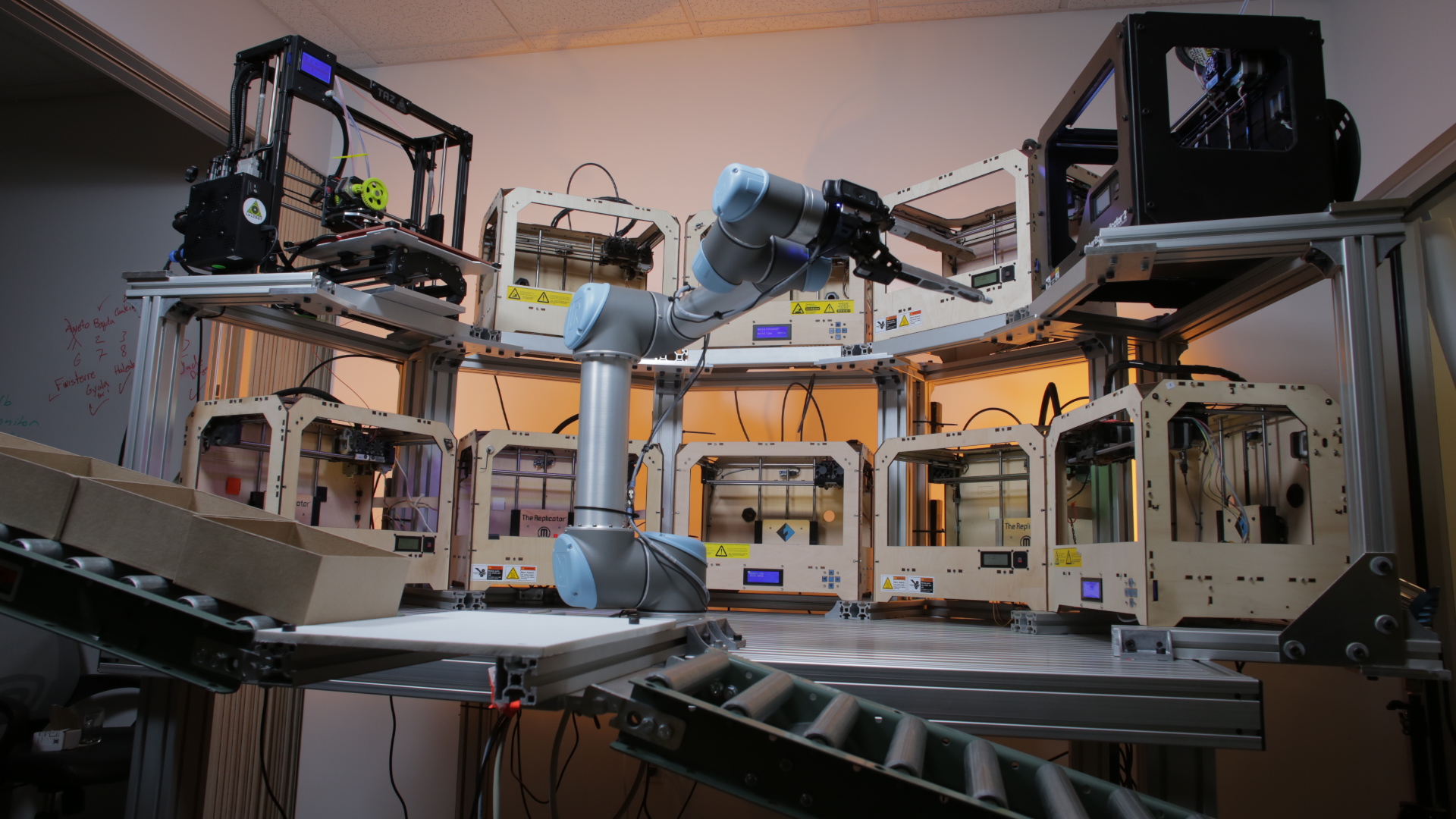

Parallel manufacturing becomes a reality. In the image above you can see how a series of desktop 3D printers have been arranged in a circle for easy access by the robot arm. This shows how you could scale up a 3D print operation into something capable of performing many print operations in parallel. In other words, the completed units-per-minute count can go way up. The printers are transformed into a kind of factory.

Shown in the video are only 3D printers, but Tend.ai can operate other machines too, such as laser cutters or CNC machines. But think of this: 3D printing is but one stage of many during the lifecycle of making an object. Consider the possibility that a robot could take a completed print and shunt it into DIFFERENT machines for post-processing. It could, for example, smooth the raw print in a tumbler before moving on to the paint station.

It’s all quite new, but very promising. I’m hopeful that either Tend.ai or their community will pump out “operational templates” that can simplify the reliable implementation of this concept.

They launch in July.

Via TechCrunch and Tend.ai