This article originates from Women In 3D Printing and is part of our effort to support the use of 3D printing technology by women. The article is re-published with permission.

Eva Wolf is the co-founder of California-based AirWolf 3D, a 3D printing equipment manufacturer.

She is telling us more about her business and what brought her into 3D printing below. We also share her thoughts about the industry and her actions to involve more women in our additive manufacturing industry.

Nora Toure: Eva, could you let us know about your background and what brought you into 3D printing?

Eva Wolf: This is my 3rd career. I have a bachelor of science in Business Management. For 15 years I worked in the government bond field, then I discovered painting and began painting murals and portraits for a living. Then 4 years ago I fell in love with 3d printing and I haven’t looked back.

Nora Toure: Could you tell us more about your first experience with 3D printing?

Eva Wolf: About 4 years ago, my husband, Erick, woke me up at 2 am so that I could check out his newly built 3D printer. It was making it’s first part – a headlight for a small scale model car. I thought it was a dream because it all seemed so surreal! He was thrilled that after weeks of building and tinkering, it was operational. To me it looked and sounded like a machine from a sci-fi film. It was unbelievable that it could make an object appear out of thin air …and it was exhilarating. I was hooked!

Nora Toure: And now, you build printers! You are the co-founder of AirWolf 3D. Could you explain to us what AirWolf 3D is?

Eva Wolf: AirWolf3D printerWe manufacture additive manufacturing equipment, consumables and accessories. Among many things, AirWolf 3D make high performance and durable desk top 3d printers for pro-sumer use. We offer printers, filaments, adhesives and educational support. A great majority of our products are sold to educators and professional engineers and designers.

We are about quality and performance. We are about 3D printing with a wide variety of engineering-grade materials. We are about making products here in the USA and creating jobs. We are about encouraging teachers to bring this technology into the classroom.

Nora Toure: How did you come up with this idea in the first place?

Eva Wolf: After watching Erick’s first 3D printer for a few minutes, I began to wonder, “Could there be a market demand for such things.” So we built a second machine and put together a classified ad on Craigslist. To my surprise, it sold within 24 hours. It was then that I knew that we were on to something. Shortly thereafter I taught myself web design, ecommerce and I created our first website. Our company was born in the garage.

Today we engineer, manufacture and ship 3d printers from our 12,000 sq. ft facility in Southern California. We offer trainings, professional workshops onsite and support our 75 resellers worldwide.

Nora Toure: How do your printers differentiate from other products on the market?

Eva Wolf: We print large parts in a variety of engineering grade materials with reliability and repeatability. Our focus is to provide companies and schools with additive manufacturing capabilities such as:

-

Printing with a wide range of materials, from low temperature TPU to stronger and lightweight Polycarbonate

-

Making large scale prototypes on a large build platform

-

Printing long beautiful print jobs

-

Safe and easy to use 3d printers that are completely enclosed

-

What do you think of the 3D printing industry today?

I have seen many changes over the last 4 years. In 2012, most of our customers where early innovators and early adapters, filled with hope, but also having realistic expectations of this newly available technology. Then there was an attempt by some larger name brands to take this technology main stream while it was still in its infancy and perhaps not ready for primetime. Now that the dust has settled and the hype is over, there is a little bit of disillusionment in the industry with users and investors. Some of this is due to less than stellar experiences with other products. The good news is that desktop 3D printing has come a long way and growth is still occurring in the education sector. It is evolving rapidly, with advancements in hardware and user friendly software making it easier than ever to 3D print. I think that more and more companies will continue to explore 3D printing to identify their competitive advance.

Nora Toure: Where do you think the industry should go?

Eva Wolf: I would like to see 3D printing used to inspire and educate more students. A 3d printer can capture the imagination of our youth and sometimes inspire them to pursue studies in STEM. A 3D printer can also help bridge the gap between a 2-dimensional CAD drawing (on a screen) and a tangible real part they can hold in their hand.

For many students, this connection creates a spark that ignites a new passion for science, technology, engineering and math. I have seen it first hand, many times, and would like for all students to have a similar experience. We work with STEM teachers to develop 3D printing lesson plans, which are available for free on our website.

As more and more classrooms adopt this technology into the curriculum, a growing future generation of graduates will be skilled with advanced 3D printing experience and perhaps contribute to the manufacturing workforce and talent pool, here in America.

Nora Toure: In your opinion, how could we encourage more women to become involved with 3D Printing?

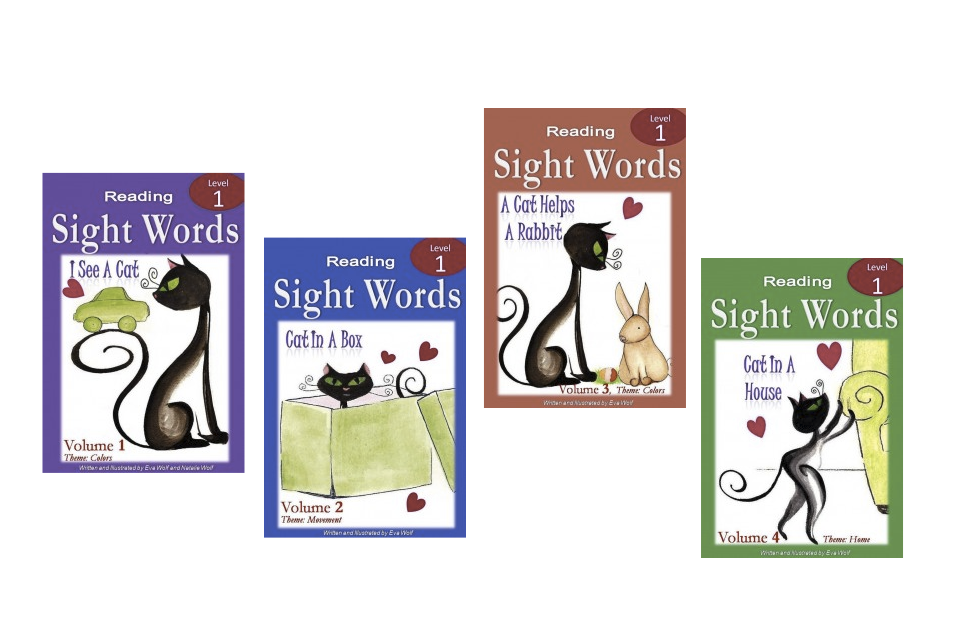

Eva Wolf: One way is to “start them young.” A 3d printer can be a STEM related tool that is gender neutral. It starts with discouraging the stigma that boys are better at engineering. Sometimes, exposure to female role models can help. My daughter and I are writing and illustrating a children’s books about 3d printing and its target audience is young girls. It is filled with inspiration case studies of girls that invent and 3D print amazing things. The estimated completion date is August 2016 and you can sign up for updates here on sightwordkids.com.

Another way is through education. Nearly half of the employees at AirWolf 3D are women and everyone is required to learn to 3d print-it is mandatory. All new Wolfpack members sit in on a 3 hour hand-on training. I have found that sometimes, my generation of women can be a little intimidated by 3D printers. However, after a few days of encouragement, we take to a 3D printer like a fish to water. I believe that feminine intuitiveness and creativity is a definite advantage for any tech company. We hold company-wide design competitions and encourage everyone to create, 3D print and participate in these challenges. It’s always interesting to see that often times women will approach old problems with a fresh perspective and innovative solutions.

You can check AirWolf 3D equipment here, and follow Eva’s & daughter’s work on the book here.

And don’t forget to join the Women in 3D Printing group on LinkedIn and Facebook.